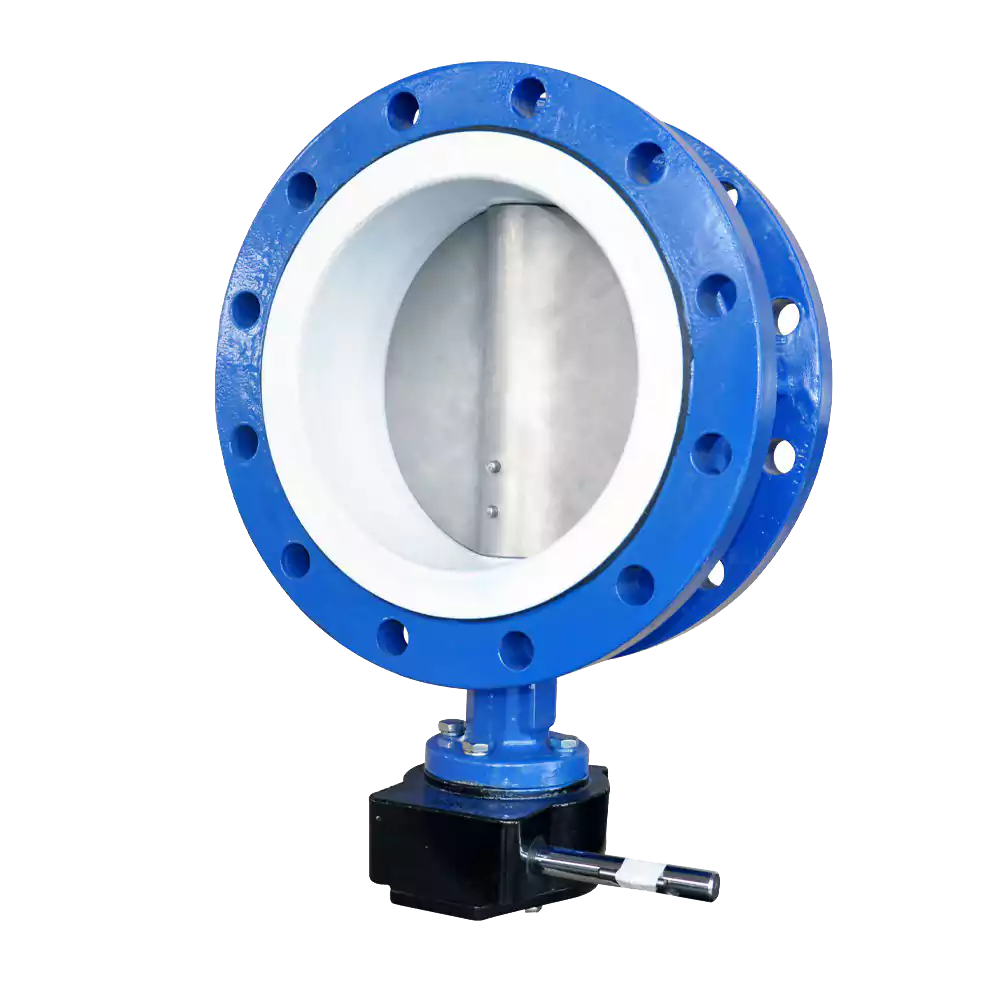

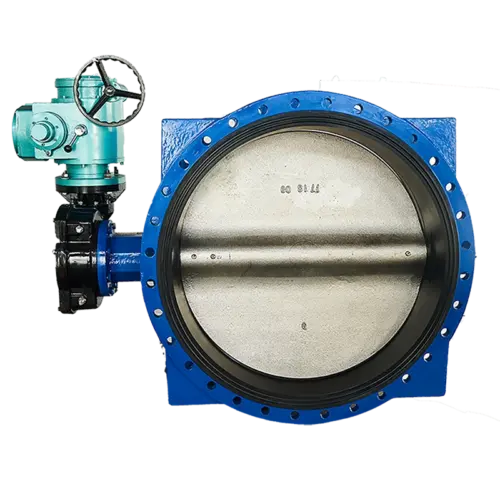

CF8M Disc PTFE Seat Flanged Butterfly Valve

Basic Info of PTFE Seat Flanged Butterfly Valve

- Ductile iron: has high tensile strength, wear, and temperature resistance. It ensures long-lasting performance and corrosion resistance. so it it a best material for soft seat butterfly valve.

- Soft valve seat: EPDM has good sealing and wear resistance, and can achieve zero leakage.

- Replaceable soft seat: When the valve seat wears, it affects use. This type of seat can be replaced without damaging the valve body. It makes maintenance easier, extends the valve’s life, and cuts maintenance costs.

- CF8M is a cast stainless steel material equivalent to 316 stainless steel.

It offers excellent corrosion resistance, making the butterfly valves suitable for handling corrosive fluids like chemicals, seawater, and food-grade substances. - The double flange design makes the soft seat butterfly valve easy to install. It suits various pipeline systems, including pipeline end systems.

Standards of Flanged Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Material of Flanged Butterfly Valve

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

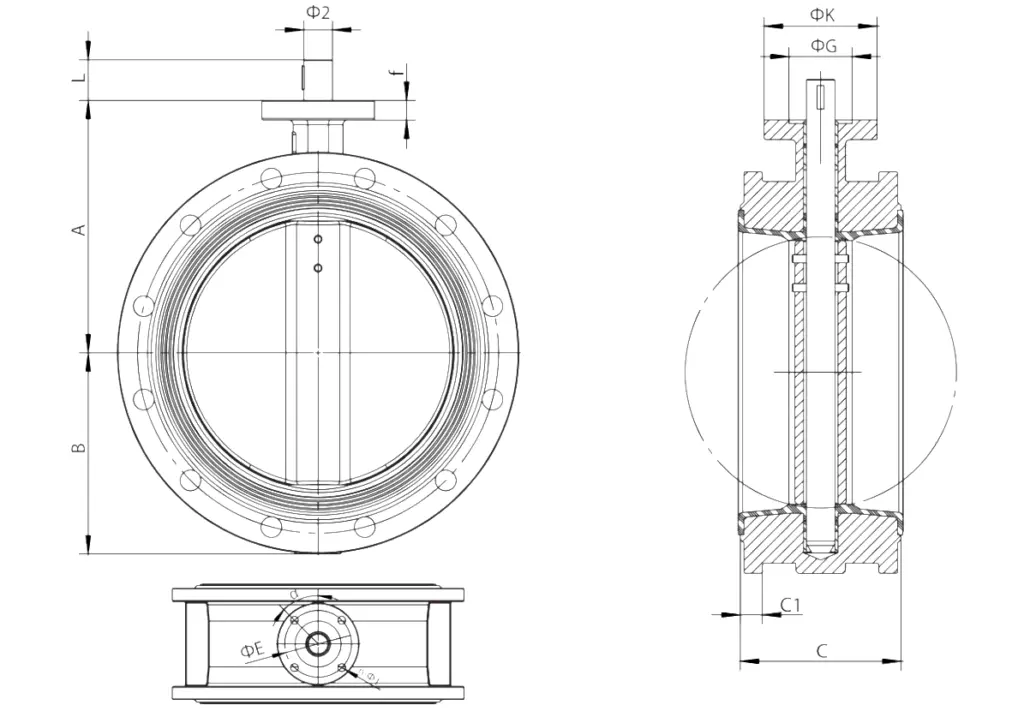

Paraments of Flanged Butterfly Valve

| DN | L | L1 | D | D1 | H | H1 | b | n-ød | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | PN1.0MPa | PN1.6MPa | PN1.0MPa | PN1.6MPa | ||||||

| 50 | 2″ | 108 | 180 | 125 | 125 | 150 | 326 | 83 | 20 | 4-ø18 | 4-ø18 |

| 65 | 2-1/2″ | 112 | 180 | 145 | 145 | 165 | 344 | 93 | 20 | 4-ø18 | 4-ø18 |

| 80 | 3″ | 114 | 180 | 160 | 160 | 200 | 363 | 100 | 22 | 4-ø18 | 8-ø18 |

| 100 | 4″ | 127 | 180 | 180 | 180 | 220 | 396 | 114 | 22 | 8-ø18 | 8-ø18 |

| 125 | 5″ | 140 | 180 | 210 | 210 | 250 | 421 | 125 | 24 | 8-ø18 | 8-ø18 |

| 150 | 6″ | 140 | 180 | 240 | 240 | 280 | 453 | 143 | 24 | 8-ø23 | 8-ø23 |

| 200 | 8″ | 152 | 270 | 295 | 295 | 335 | 578 | 170 | 26 | 8-ø23 | 12-ø23 |

| 250 | 10″ | 165 | 270 | 350 | 355 | 405 | 638 | 198 | 26 | 12-ø23 | 12-ø28 |

| 300 | 12″ | 178 | 380 | 400 | 410 | 455 | 731 | 223 | 32 | 12-ø23 | 12-ø28 |

| 350 | 14″ | 190 | 380 | 460 | 470 | 525 | 783 | 270 | 36 | 16-ø23 | 16-ø28 |

| 400 | 16″ | 216 | 450 | 515 | 525 | 580 | 888 | 300 | 38 | 16-ø28 | 16-ø31 |

| 450 | 18″ | 222 | 480 | 565 | 585 | 640 | 958 | 340 | 40 | 20-ø28 | 20-ø31 |

| 500 | 20″ | 229 | 480 | 620 | 650 | 705 | 1005 | 355 | 42 | 20-ø28 | 20-ø34 |

| 600 | 24″ | 267 | 480 | 725 | 770 | 825 | 1128 | 410 | 48 | 20-ø30 | 20-ø36 |

| 700 | 28″ | 292 | 640 | 840 | 840 | 920 | 1476 | 478 | 53 | 24-ø30 | 24-ø36 |

| 800 | 32″ | 318 | 640 | 950 | 950 | 1020 | 1533 | 525 | 58 | 24-ø33 | 24-ø39 |

| 900 | 36″ | 330 | 750 | 1050 | 1050 | 1120 | 1655 | 585 | 65 | 28-ø33 | 28-ø39 |

| 1000 | 40″ | 410 | 850 | 1160 | 1170 | 1340 | 1765 | 640 | 76 | 28-ø36 | 28-ø42 |

| 1200 | 48″ | 470 | 850 | 1380 | 1390 | 1560 | 1995 | 755 | 85 | 32-ø39 | 32-ø48 |

| 1400 | 56″ | 530 | 1000 | 1590 | 1590 | 1760 | 2310 | 910 | 103 | 36-ø42 | 36-ø48 |

| 1600 | 64″ | 600 | 1000 | 1820 | 1820 | 1970 | 2595 | 1030 | 123 | 40-ø48 | 40-ø56 |

| 1800 | 72″ | 697 | 1100 | 2020 | 2020 | 2180 | 2810 | 1140 | 135 | 44-ø48 | 44-ø56 |

| 2000 | 80″ | 760 | 1100 | 2230 | 2230 | 2345 | 3100 | 1250 | 145 | 48-ø48 | 48-ø56 |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia