Invitation to Visit ZFA VALVE at FENASAN 2024

Invitation to Visit Us at FENASAN 2024 Dear Valued Customer, We are excited to invite...

Top Factors to Consider When Choosing a Reliable Valve Manufacturer in China

The Chinese manufacturing market is very diverse. Many manufacturers produce high-quality valves, and everyone claims...

Butterfly Valve Seat Types and Selection Guide

Butterfly valves are versatile and efficient devices for flow control. They are found in many...

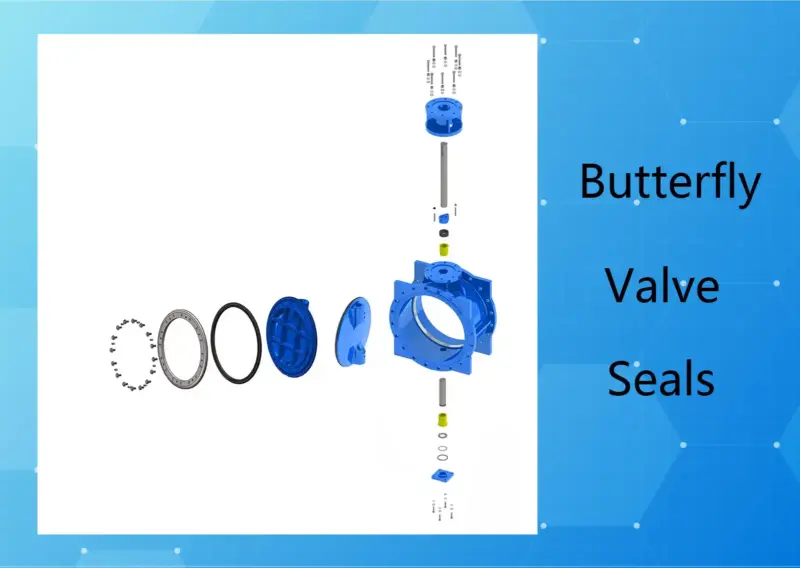

A Comprehensive Guide to Butterfly Valve Seals

1. Introduction to Butterfly Valve Seals A butterfly valve is a quarter-turn rotary valve that...

Understanding API Standards For Valves

The world of valves is vast. They are critical for diverse industries, including oil, gas,...

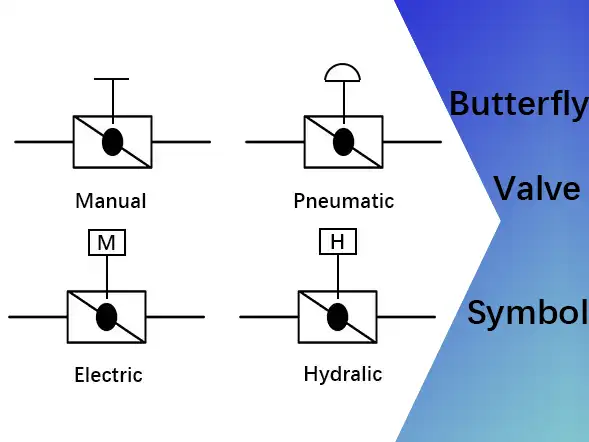

Butterfly Valves Symbol

1. Introduction to Butterfly Valves 1.1. What is a Butterfly Valve? A butterfly valve is...

Russian WASTETECH/ECWATECH Exhibition Invitation

Dear Customer: We sincerely invite you to attend the upcoming Exhibition WASTETECH/ECWATECH in Russia. As...

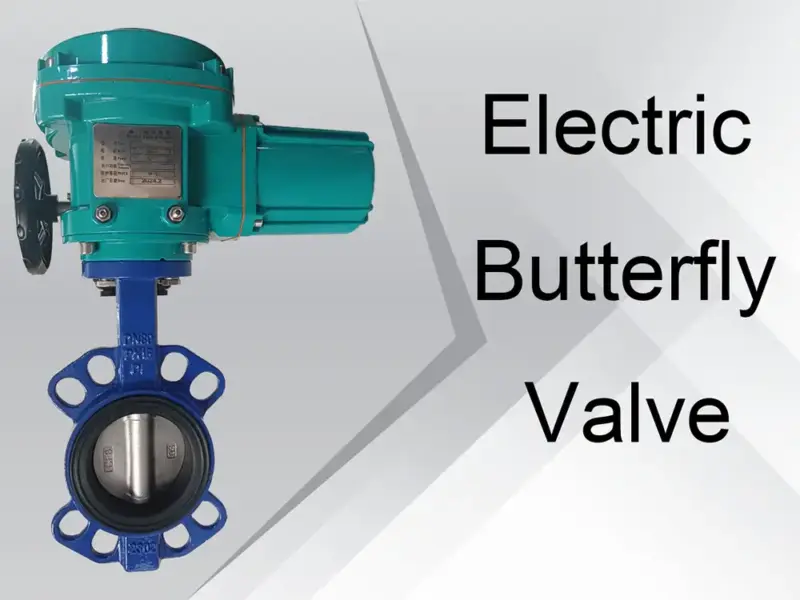

How Electric Butterfly Valves Work: A Complete Guide

1. Understand Electric Butterfly Valve Components Electric butterfly valves have five main parts: valve body,...

High Performance Butterfly Valves for Industrial Applications

Compared to general service butterfly valves, high performance butterfly valves provide superior operating performance. The...

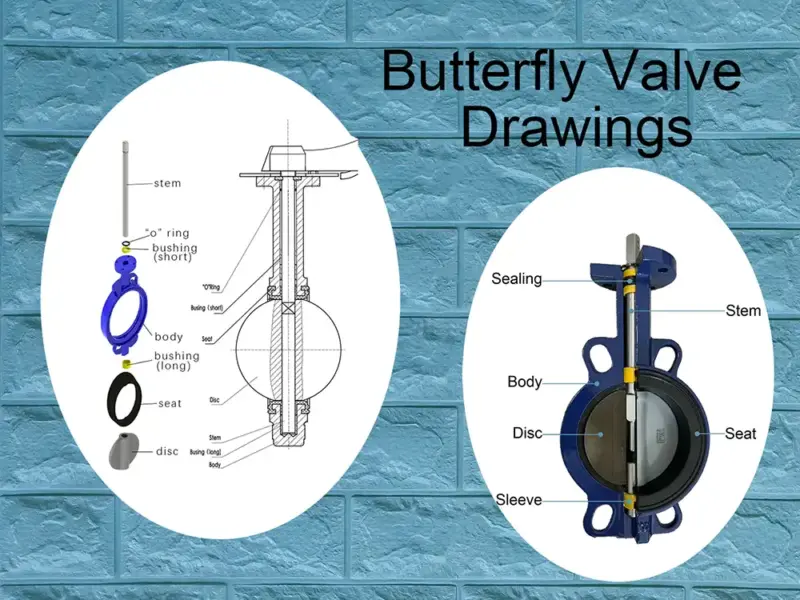

Importance of Butterfly Valve Drawings

1. Brief Introduction Creating a detailed document describing every aspect of butterfly valve drawings can...