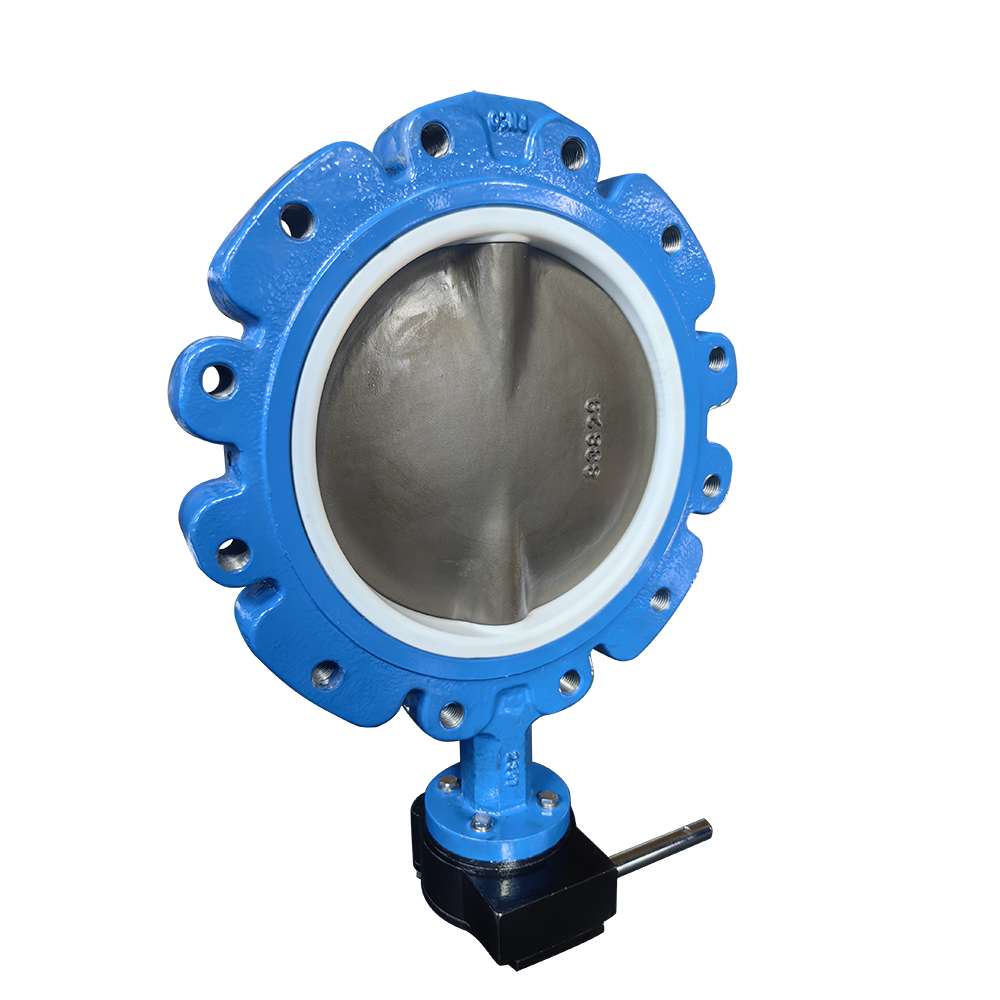

PFA Lined CF3M Disc PTFE Lug Butterfly Valve

Features of PFA Lined Lug Butterfly Valve

- PFA-lined cf3m disc: CF3M is equivalent to SS316L, but has enhanced corrosion resistance, making it ideal for highly corrosive environments. So the PFA-lined disc has superior chemical resistance compared to PTFE. It can handle highly corrosive chemicals such as hydrofluoric acid, nitric acid, and strong bases.

- Excellent high temperature performance: PFA material can withstand high temperature environments, ensuring the reliability and performance stability of the valve under high temperature conditions.

- PTFE seat: Well-known as the king of plastics, it provides a non-stick surface and chemical compatibility with a wide range of fluids.

- Simple structure and operation: The PTFE lug butterfly valve adopts a simple structural design. It is easy to operate and does not require complicated maintenance work, and it can reduce maintenance costs and operation difficulty.

- Lug design enables the valve to be installed in a pipeline where one side of the pipeline can be removed without disturbing the other side.This is called dead end service.

- The worm gear transfer rotational motion from a handwheel into linear motion to rotate the PTFE lug butterfly valve disc.

Material Options of Lug Butterfly Valve

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Standards of PFA Lined Disc Lug Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

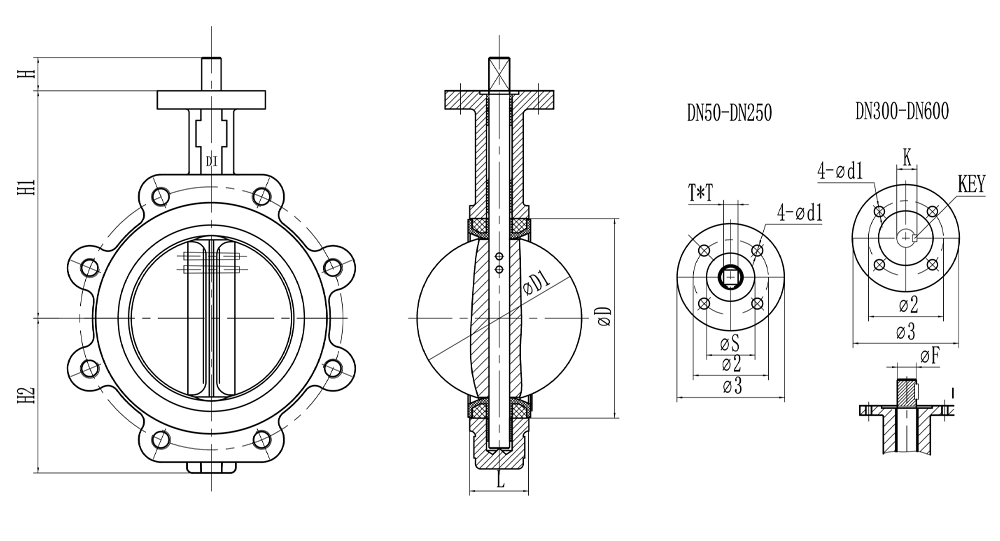

Paraments of Hard-Back Seat Lug Butterfly Valve

| SIZE | øD | øD1 | L | H | H1 | H2 | ø2 | ø3 | 4-ød1 | T*T |

|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 76.3 | 52.8 | 42 | 30 | 140 | 60 | 70 | 90 | 10 | 11 |

| DN65 | 89 | 64.6 | 45 | 30 | 150 | 67 | 70 | 90 | 10 | 11 |

| DN80 | 103.9 | 79.1 | 45 | 30 | 160 | 87 | 70 | 90 | 10 | 11 |

| DN100 | 135 | 104.4 | 51 | 30 | 180 | 105 | 70 | 90 | 10 | 11 |

| DN125 | 159 | 123.3 | 55 | 30 | 190 | 118 | 70 | 90 | 10 | 14 |

| DN150 | 188.4 | 155.6 | 55 | 30 | 210 | 130 | 70 | 90 | 10 | 14 |

| DN200 | 238.2 | 202.5 | 59 | 35 | 235 | 166 | 102 | 125 | 12 | 17 |

| DN250 | 292.4 | 250.5 | 66.6 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 344.2 | 301.6 | 76.5 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

| DN350 | 375.2 | 333.4 | 76.5 | 35 | 360 | 255 | 125 | 150 | 14 | 22 |

| DN400 | 439.5 | 389.6 | 101.5 | 50 | 381 | 293 | 140 | 175 | 18 | 27 |

| DN450 | 490.5 | 440.5 | 113.5 | 50 | 425 | 325 | 140 | 175 | 18 | 27 |

| DN500 | 535.4 | 491.6 | 126.2 | 50 | 470 | 363 | 140 | 175 | 18 | 36 |

| DN600 | 653.7 | 592.5 | 153.2 | 60 | 565 | 425 | 165 | 210 | 22 | 36 |

Application of PFA Lined Butterfly Valve

- Chemical Processing Plants:

- Pharmaceutical and Biotech Industries:

- Semiconductor and Electronics Manufacturing

- Pulp and Paper Industry

- Mining and Metallurgy

- Water Treatment and Desalination

- Food and Beverage Industry

- Oil and Gas Industry

Manufacture Process of Butterfly Valve

Certificates of Zfa Butterfly Valve Company

WRAS

CE

ISO 9001

EAC Russia