Wholesale Bare Shaft SS CF8 Body Soft Seal Lug Butterfly Valves

Features of CF8 Lug Butterfly Valves

- CF8 is a cast stainless steel. It is similar to AISI 304 stainless steel. Stainless steel CF8 lug butterfly valves have excellent corrosion resistance. So they are suitable for a wide range of corrosive applications.

-

A “dovetail replaceable soft back seat” for a lug butterfly valve is a fully lug wafer butterfly valve with a replaceable EPDM soft seat. It reduces costs when the seat is broken.

-

EPDM valve seats have high elasticity and resilience. They seal the valve and prevent leaks. They have excellent sealing and chemical resistance. Also, it has excellent chemical stability. It can resist corrosion and erosion from many chemicals, so it suits various media.

-

Temperature adaptability: EPDM valve seats can work in a wide temperature range. They resist heat and cold from minus 20 to 80 degrees Celsius.

-

Centerline design: This lug butterfly valve has a centerline design. It makes the valve action more stable and accurate. It reduces the opening and closing torque. This improves performance and ease of use.

-

The oringin of the Best Lug butterfly valve is China.

-

Zfa valve wholesale cf8 lug butterfly valves all over the world.

Material Options of Lug Butterfly Valves

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

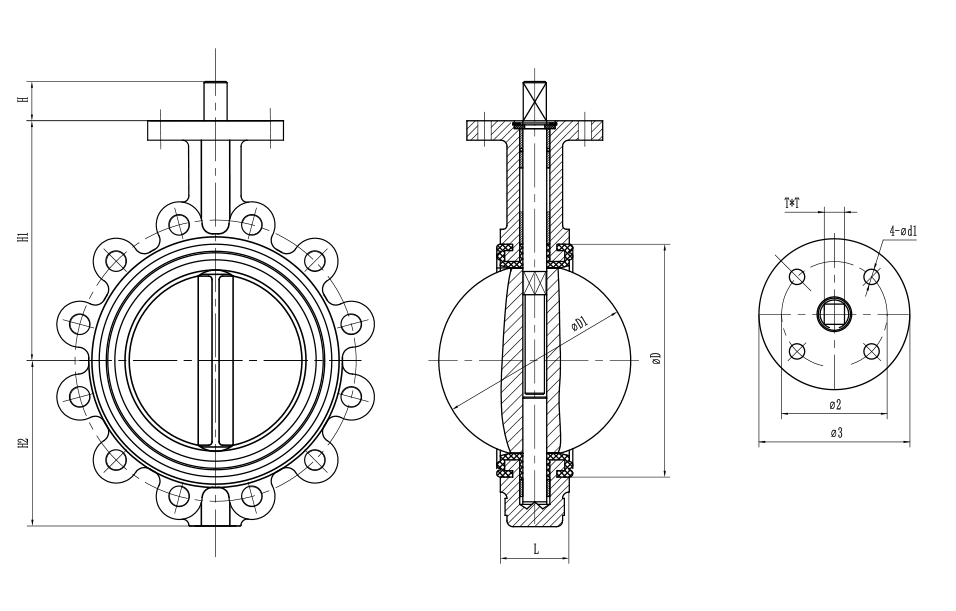

Paraments of Bare Shaft Lug Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ∅2 | ø3 | 4-ødl | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 76.3 | 52.8 | 43 | 46 | 30 | 140 | 60 | 70 | 90 | 10 | 11*11 |

| DN65 | 89 | 64.6 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11*11 |

| DN80 | 103.9 | 79.1 | 45.6 | 48 | 30 | 160 | 87 | 70 | 90 | 10 | 11*11 |

| DN100 | 135 | 104.4 | 52.0 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11*11 |

| DN125 | 159 | 123.3 | 56.0 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14*14 |

| DN150 | 188.4 | 155.6 | 56.0 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14*14 |

| DN200 | 238.2 | 202.5 | 60.0 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68.0 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78.0 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22*22 |

| DN350 | 375.2 | 333.4 | 78.0 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22*22 |

| DN400 | 439.5 | 389.6 | 102.0 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27*27 |

| DN450 | 490.5 | 440.5 | 114.0 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127.0 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36*36 |

| DN600 | 653.7 | 592.5 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36*36 |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia