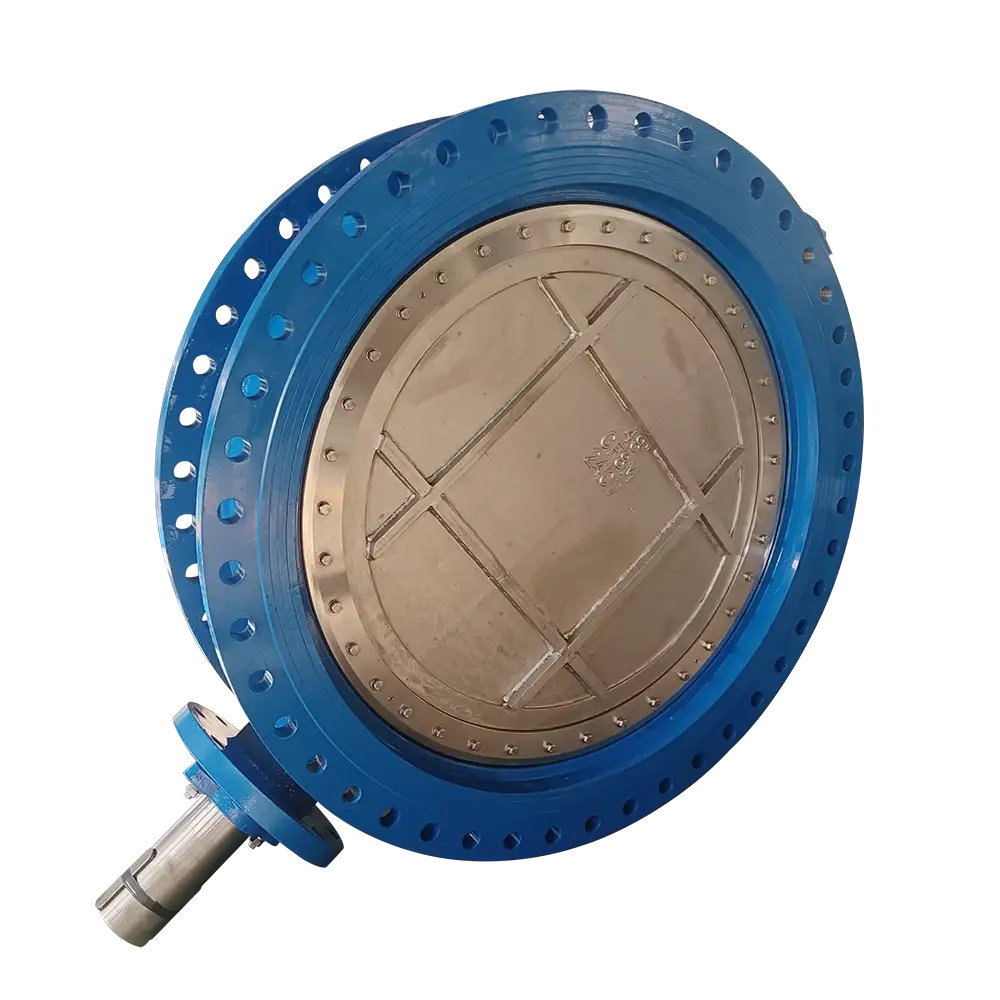

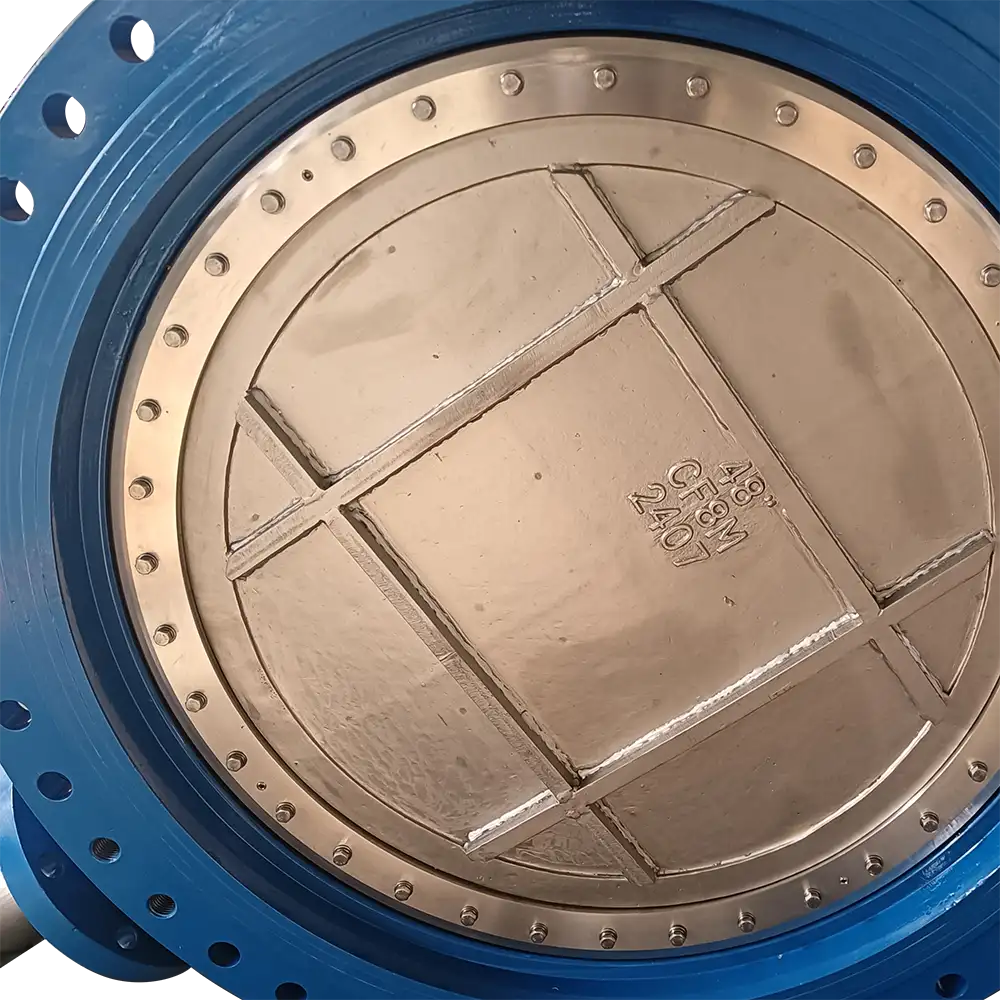

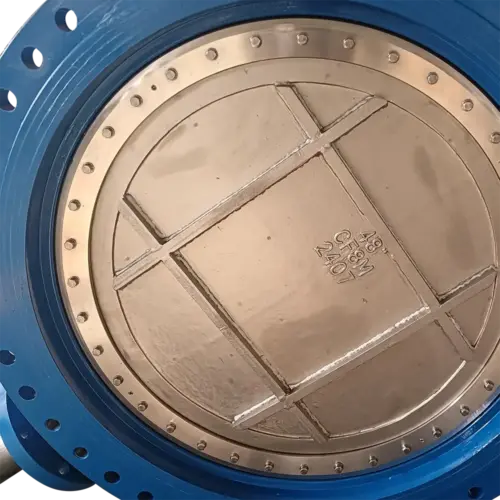

CF3M Disc Double Offset Butterfly Valve Bidirectional Sealing

Basic Info of Double oOffset Butterfly Valve

- CF3M (316L stainless steel) disc offers excellent corrosion resistance. so the double eccentric butterfly valves are ideal for harsh environments and chemical applications.

- Double Offset design maximally reduces seat wear, minimizes friction, and enhances sealing performance for extended service life.

- Bidirectional Tight Sealing ensures leak proof in both side flow directions.

- The double offset butterfly valve design reduces the torque required for operation, allowing for smaller actuators and cost savings.

- The double offset butterfly valve can be operated manually (gearbox) or automated with pneumatic, electric, or hydraulic actuators.

- The doubke eccentric butterfly valves are esigned to meet international standards like API 609, AWWA C504, ISO 5752, and ASME B16.34 for reliability and safety.

Double Offset Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Worm Gear, Electric, Pneumatic | |||

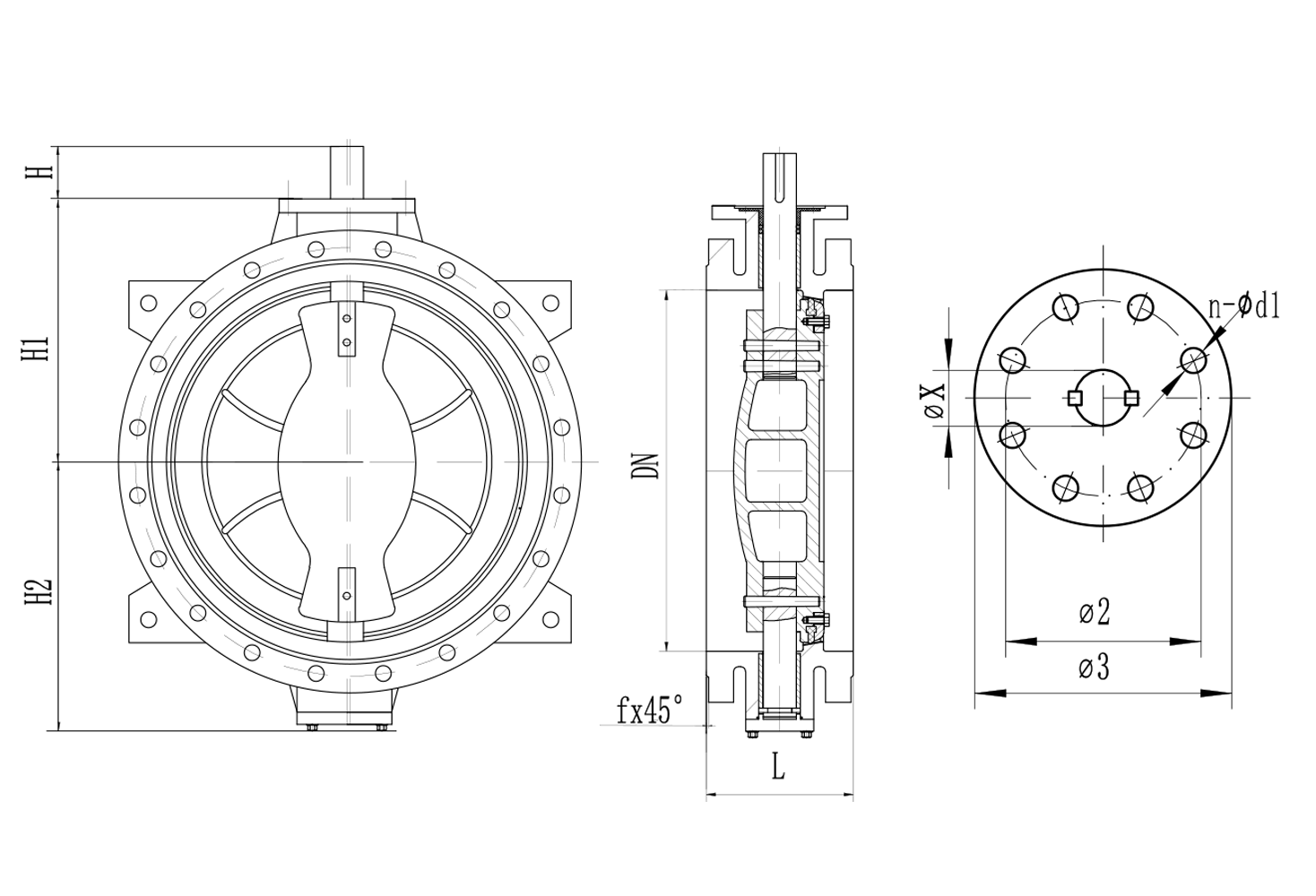

Paraments of Double Eccentric Butterfly Valve

| SIZE | H1 | H2 | L | f | ø2 | ø3 | n-ød1 | øX |

|---|---|---|---|---|---|---|---|---|

| DN100 | 178 | 123 | 190 | 3 | 70.0 | 90.00 | 4-10 | 20 |

| DN150 | 217 | 162 | 210 | 3 | 102.0 | 125.00 | 4-12 | 20 |

| DN200 | 250 | 175 | 230 | 3 | 102.0 | 125.00 | 4-12 | 25 |

| DN250 | 281 | 206 | 250 | 3 | 102.00 | 125.00 | 4-12 | 30 |

| DN300 | 306 | 246 | 270 | 4 | 125.00 | 150.00 | 4-14 | 34 |

| DN350 | 334 | 284 | 290 | 4 | 140.0 | 175.00 | 4-18 | 33 |

| DN400 | 374 | 304 | 310 | 4 | 140.0 | 175.00 | 4-18 | 41 |

| DN500 | 433 | 375 | 350 | 4 | 165.0 | 210.00 | 4-22 | 51 |

| DN600 | 493 | 436 | 390 | 5 | 165.0 | 210.00 | 4-22 | 51 |

| DN800 | 581 | 574 | 470 | 5 | 254.0 | 300.00 | 4-18 | 85 |

| DN900 | 692 | 606 | 510 | 5 | 254.0 | 300.00 | 4-18 | 85 |

| DN1000 | 722 | 685 | 550 | 5 | 254.0 | 300.00 | 8-18 | 85 |

| DN1200 | 845 | 796 | 630 | 5 | 298.0 | 350.00 | 8-22 | 105 |

Manufacture Process

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia