Soft Back Seat Nylon Coated Disc Wafer Butterfly Valve

Basic Info

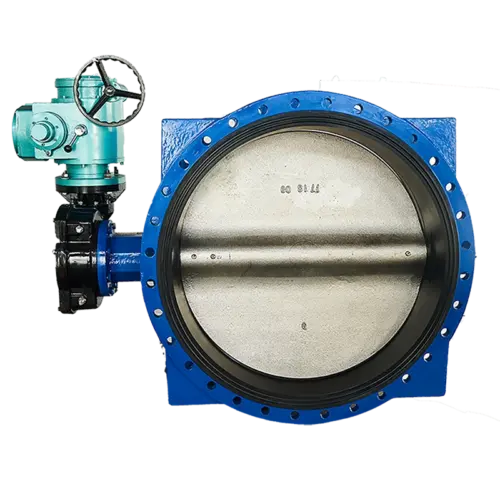

- Compared with the hard-backed valve seat, the soft-backed valve seat has a wider contact surface with the pipe flange, and the installation and sealing performance is better, without the need for a special flange for butterfly valves;

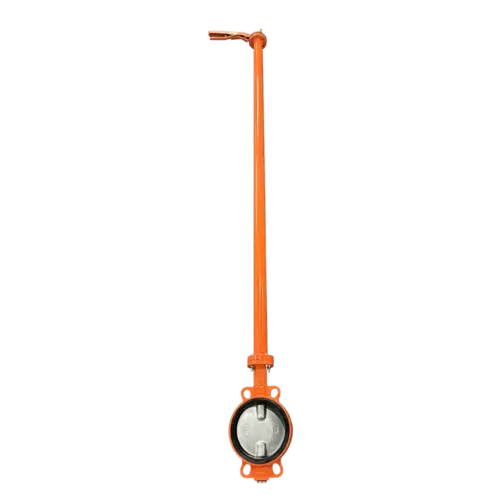

- A long neck butterfly valve is a type of butterfly valve designed with an extended stem or neck.

- The long neck allows the valve to be operated from above ground. So it is a popular choice for buried or underground pipeline systems.

- The long neck keeps the valve actuator or handle accessible above the insulation layer. It is deal for systems that require thermal insulation, such as in HVAC, chemical processing, and certain water treatment applications.

- Two shafts ensure low pressure drop, smoother opening and closing, allowing for more precise flow regulation.

Paraments

| SIZE | D1 | D2 | D3 | N×φD | α° | F | G | A | B | C | E |

| DN50(2″) | 52.6 | 100 | 120.6 | 4×19 | 45 | 52 | 266.7 | 273 | 161 | 43 | 32 |

| DN100(4″) | 104 | 156 | 190.5 | 8×19 | 22.5 | 52 | 266.7 | 346 | 200 | 52.1 | 32 |

| DN150(6″) | 155.6 | 212 | 241.3 | 8×22. | 422.5 | 52 | 266.7 | 397 | 226 | 55.8 | 32 |

| DN200(8″) | 202.4 | 264 | 298.4 | 8×22. | 422.5 | 52 | 359 | 485 | 260 | 60.6 | 45 |

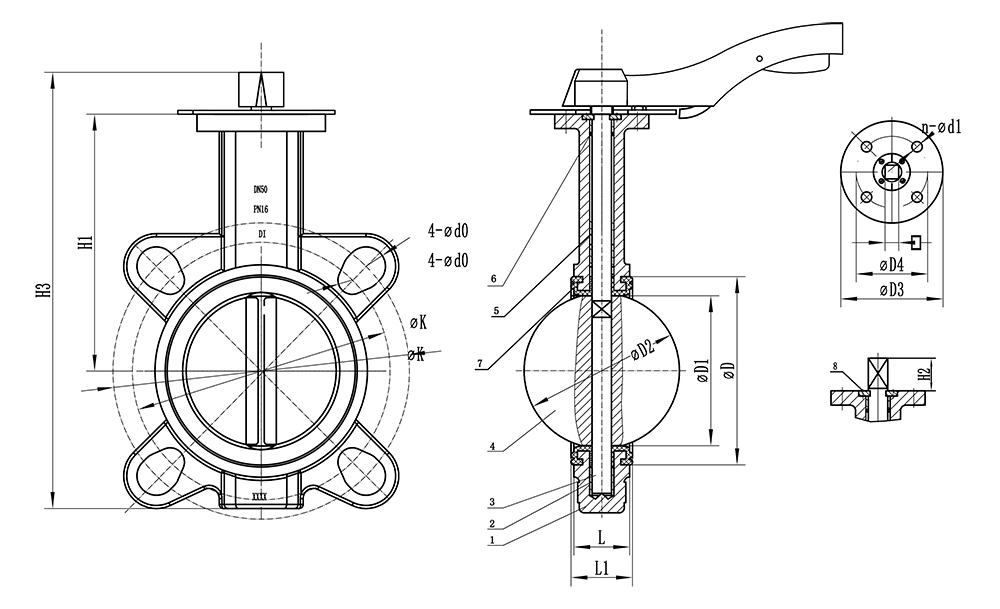

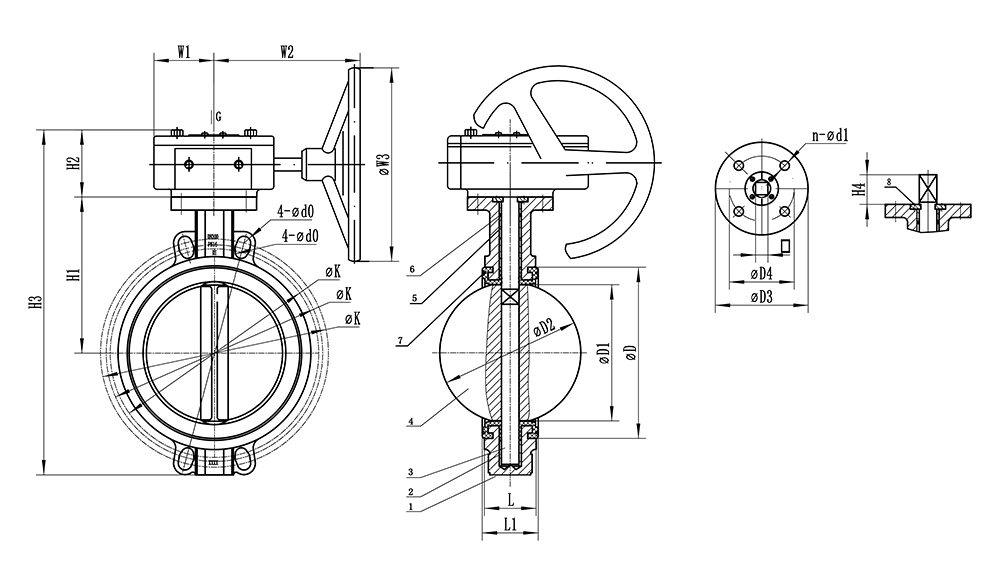

| SIZE | øK | 4-ød0 | øD | øD1 | øD2 | L | L1 | H1 | H2 | H3 | øD3 | øD4 | n-ød1 | □ | H4 | W1 | W2 | øW3 | |||||||

| PN6 | PN10 | PN16 | CL150 | PN6 | PN10 | PN16 | CL150 | ||||||||||||||||||

| DN200 | 8〞 | 280 | 295 | 295 | 298.5 | 4-ø19 | 4-ø23 | 4-ø23 | 4-ø22.3 | 246 | 194 | 202 | 60 | 64 | 235 | 86 | 487 | 125 | 102 | 4-012 | □17 | 35 | 75 | 238 | 300 |

| DN250 | 10〞 | 335 | 350 | 355 | 362 | 4-ø19 | 4-ø23 | 4-ø28 | 4-ø25.4 | 301.5 | 241 | 250 | 68 | 72 | 270 | 86 | 553 | 125 | 102 | 4-ø12 | □22 | 35 | 75 | 238 | 300 |

| DN300 | 12〞 | 395 | 400 | 410 | 431.8 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø25.4 | 352 | 290 | 301 | 78 | 83 | 310 | 118 | 658 | 25 | 102 | 4-ø12 | □22 | 35 | 81 | 227 | 300 |

| DN350 | 14〞 | 445 | 460 | 470 | 476.3 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø28.6 | 390 | 325.4 | 333.3 | 78 | 83 | 360 | 118 | 733 | 150 | 125 | 4-ø14 | □22 | 35 | 81 | 227 | 300 |

| DN400 | 16〞 | 495 | 515 | 525 | 539.8 | 4-ø23 | 4- ø 28 | 4-ø31 | 4-ø28.6 | 452 | 377 | 387 | 102 | 106 | 380 | 150 | 821 | 175 | 140 | 4-018 | □27 | 50 | 115 | 278 | 300 |

| DN500 | 20〞 | 600 | 620 | 650 | 635 | 4-ø23 | 4-ø28 | 4-ø34 | 4-ø31.8 | 564 | 480 | 491.6 | 127 | 132 | 470 | 150 | 981 | 175 | 140 | 4-ø18 | □27 | 50 | 115 | 278 | 300 |

| DN600 | 24〞 | 705 | 725 | 770 | 749.3 | 4-ø26 | 4-ø31 | 4-ø37 | 4-ø35 | 649.5 | 579.9 | 592.5 | 153 | 159 | 495 | 180 | 1120 | 210 | 165 | 4-022 | □36 | 60 | 144 | 304 | 300 |

Manufacture Process

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia