CF8M Disc Soft Seat Lug 10 Butterfly Valve with Worm Gear

Features of 10 inch Lug Butterfly Valve

- Lug Butterfly Valve can be used for dead end service, it means the end of the pipeline, as there are threads in the ears, it is more stable than the wafer butterfly valve. So it allows replacement of one side of the pipe without affecting the other side.

- 10-Inch (DN250) is suitable for medium to large pipelines in industrial or municipal systems.

- Temperature adaptability: EPDM valve seats can work normally in a wide temperature range, with good heat resistance and cold resistance from – 20 to 80 degrees.

- Centerline design: This lug butterfly valve makes the valve action more stable and accurate, reduces the opening and closing torque.

- Stainless steel CF8M Disc (equivalent of 316 stainless steel), has excellent corrosion resistance, especially against chlorides and harsh chemicals.

- CF8M Disc and EPDM Seat are ideal for applications in chemical processing, and water treatment.

- Soft Seat is usually made of EPDM, and NBR, providing a bubble-tight seal and excellent flexibility for various temperature and pressure ranges.

- Lug Type Design Features threaded lugs on the valve body, allowing it to be bolted directly to the pipe flanges. This design enables easy removal of one side of the pipeline for maintenance without disrupting the other side.

- Worm Gear Actuator Provides smooth and precise operation by converting a small rotational input into a larger torque.

10 inch Lug Butterfly Valve Standard

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

10 inch Lug Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

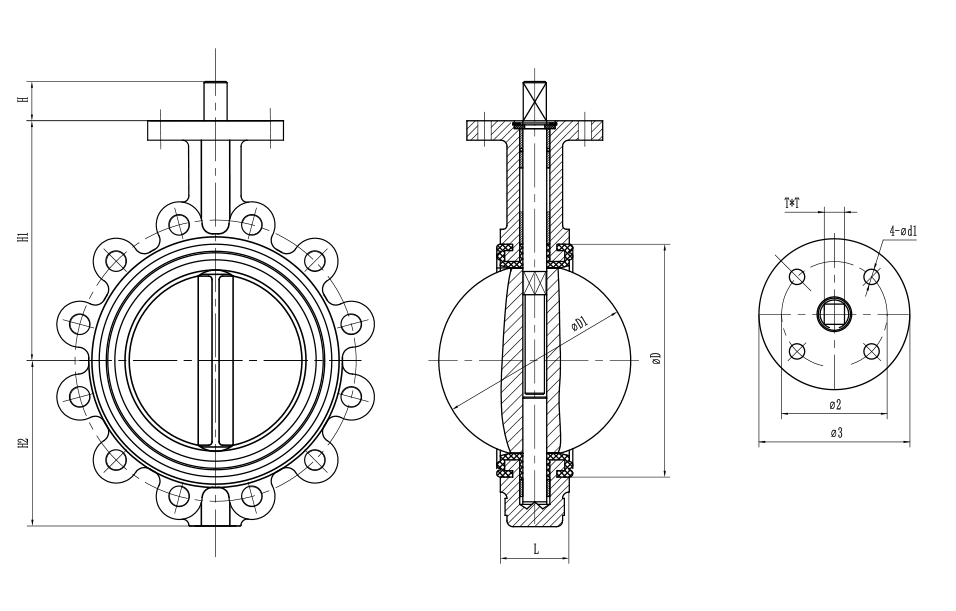

Paraments of Lug 10 Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ∅2 | ø3 | 4-ødl | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 76.3 | 52.8 | 43 | 46 | 30 | 140 | 60 | 70 | 90 | 10 | 11*11 |

| DN65 | 89 | 64.6 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11*11 |

| DN80 | 103.9 | 79.1 | 45.6 | 48 | 30 | 160 | 87 | 70 | 90 | 10 | 11*11 |

| DN100 | 135 | 104.4 | 52.0 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11*11 |

| DN125 | 159 | 123.3 | 56.0 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14*14 |

| DN150 | 188.4 | 155.6 | 56.0 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14*14 |

| DN200 | 238.2 | 202.5 | 60.0 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68.0 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78.0 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22*22 |

| DN350 | 375.2 | 333.4 | 78.0 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22*22 |

| DN400 | 439.5 | 389.6 | 102.0 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27*27 |

| DN450 | 490.5 | 440.5 | 114.0 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127.0 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36*36 |

| DN600 | 653.7 | 592.5 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36*36 |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia