Determining whether a valve is open or closed ensures efficient and safe operations. Butterfly and ball valves provide clear visual indicators through handle orientation for easy identification. Globe and gate valves, however, present challenges with no obvious visual cues. Identifying their operational status requires understanding the basic and working of gate valve. This article will discuss when the gate valve open or closed and how it works correctly.

What is a Gate Valve?

A gate valve is a mechanical device that regulates fluid flow in pipelines. The valve possesses a gate or open or closed wedge. The gate regulates the fluid flow through the pipeline. The valve does not restrict the flow of fluids when it is fully open. This characteristic makes it ideal for high-pressure, large-diameter applications across different industries. When the valve is closed, the gate firmly seals against the body. The sealing stops any leakage from the valve. The gate uses hard materials such as cast iron, stainless steel, or brass. These materials are selected according to the specific requirements of the application.

How Does a Gate Valve Work?

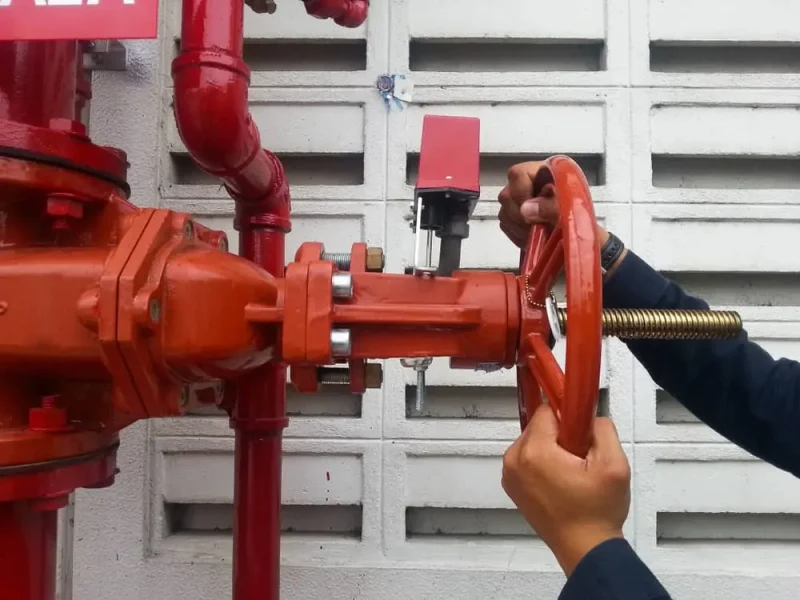

Knowing how a gate valve operates is important to use it properly. Gate valves operate by moving a wedge-shaped gate up or down within the valve body to regulate the flow of liquid or gas. The valve consists of two primary parts: the gate (or wedge) and the valve stem. The stem is attached to a handwheel or actuator, which is employed to open or close the valve.

As you rotate the handwheel or actuator, the stem operates the gate. When the gate opens, it forms an entrance for fluid flow. During closing, the gate descends and wedges against the body. This fully shuts off the flow to prevent leakage. Gate valves are not suitable for flow regulation or throttling. They are used only in fully open or fully closed positions. That is why they are best for on/off processes.

Gate Valve Diagram and Parts

A basic diagram of a gate valve shows the various parts and how they work together. The principal components of a gate valve are the body, gate, seat, stem, bonnet, and actuator. The gate, or wedge, travels up and down inside the valve to regulate the flow. The seat is the surface on which the gate closes when the valve is closed. The stem joins the actuator to the gate so the operator can manipulate the valve.

The movement of the valve stem is utilized by an actuator in the form of a handwheel, gear mechanism, or electric motor. You would have the valve body, stem that rises or lowers, and gate that will move up or down while a valve opens or closes from the typical gate valve diagram. Understanding every component within the gate valve diagram is crucial for knowing how a valve functions and operates.

Gate Valve Open or Closed: The Correct Operation

When using, the critical aspect to remember is whether you want the gate valve open or closed. The valve turn direction that you use to get these positions is referred to as the gate valve open-close direction. You must properly open and close the valve to prevent damage to the valve, system, or pipework.

1. Opening a Gate Valve

To open a gate valve, turn the actuator or handwheel counterclockwise. This motion will raise the gate, allowing the fluid to flow freely through the pipe. Turn the wheel slowly and steadily, ensuring the valve is fully open before stopping. If the valve is not fully open, it may obstruct or restrict flow, which could cause inefficiency or damage to the system.

2. Closing a Gate Valve

To shut the gate valve, rotate the actuator or handwheel clockwise. This will close the gate and form a seal that prevents fluid flow. Upkeep should be taken to shut the valve slowly without applying too much force. Forcing the valve may ruin the internal parts or jam the gate. Always make sure the gate valve is completely closed during shutdown to avoid any leakage.

Gate Valve Open or Closed: Common Mistakes to Avoid

Among the most common faults in operating a gate valve is not opening or closing it. Partially leaving the valve open can result in fluid flow restrictions that destroy the system. Closing the valve too abruptly can also produce leaks and wastage. A partially open or closed valve may quickly wear out if left as such.

Always verify the direction marked on the valve for proper actuator travel. Some valves have labels indicating the right direction, but this is not always the case. If no label has been used, consider that the valve opens counterclockwise and closes clockwise. This simple rule prevents errors during usage and ensures effective performance.

Gate Valve Open Close Direction: Tips for Proper Operation

To avoid mistakes, it’s helpful to remember the gate valve’s open-close direction. Generally, a gate valve opens counterclockwise and closes clockwise. Some gate valves may have different designs, especially in more complex systems. If unsure, turn the valve slowly in both directions to confirm.

In many industrial settings, gate valves are equipped with actuators or automated systems. These systems are especially useful in large-scale operations where manual operation is inefficient. Despite the system type, the basic principle of gate valve operation remains the same. Whether using a handwheel or automated actuator, the valve operates similarly.

Conclusion

Gate valves are an essential component in many industrial systems. They provide a reliable way to control fluid flow. Understanding what a gate valve is and how it works properly is important. Knowing the correct gate valve opening or closing procedure can help prevent system issues.

Always follow the gate valve open-close direction using a handwheel or an actuator. This will help you avoid mistakes and ensure efficient operation. It shows the internal components and how they work together. You can ensure its smooth operation by following the proper procedures for opening and closing a gate valve.