A check valve is a vital part of any fluid system, ensuring proper flow of fluids. But have you ever wondered what makes a valve “click” open and allows fluid flow? That’s where cracking pressure comes into play. But what is check valve cracking pressure, and how does it impact the performance of the whole system?

Knowing the answer is crucial before installing the check valve. Without the proper cracking pressure, the valve will fail to open or cause an overflow, resulting in pipe wear. Are you dealing with a check valve and new to the cracking pressure concept? Worry not! This guide will help you understand the check valve’s cracking pressure. Let’s get started!

What Is Check Valve Cracking Pressure?

The minimum pressure required to open a check valve is called cracking pressure. It is measured in PSI or bar. When the pressure of liquid overcomes the resistance of the check valve and pushes it to open, it is referred to as its cracking pressure. The value of cracking pressure varies with the type of valve.

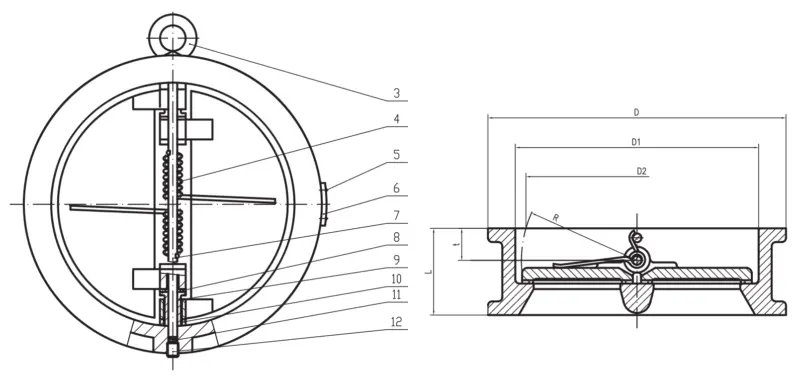

As you know, check valves are used in gas or fluid systems to prevent backflow. In simple words, check valves ensure fluid flow in a single direction. These valves have a disc, spring, or ball that remains closed when there is no pressure on the backside. However, when the fluid reaches the near valve, it imparts pressure on the disc.

If this pressure exceeds the valve resistance, it forces the disc to open, and fluid starts passing. This pressure is known as the cracking pressure of a check valve. However, the valve remains closed if the liquid or gas cannot impart enough pressure. The term cracking means slight and slow opening. When you apply pressure on the check valve, it doesn’t open instantly.

Instead, it opens slightly, allowing a small amount of fluid to pass. When pressure increases further, the valve opens fully and allows more flow. Remember, if the cracking pressure is too low, it will not be enough to open a valve. However, if the cracking pressure is too high, it will cause distortion. Thus, proper cracking pressure is crucial to maintaining system efficiency.

How to Calculate Cracking Pressure For Check Valves?

Calculating cracking pressure is crucial to work the valve effectively. If it is too high or too low, the valve will not open or cause leakage. So, how would you calculate the exact cracking pressure? Let’s find out in a few easy steps.

Step 1: Identify Valve Specifications

This is the first and most important step in calculating pressure cracking. To check valve specifications, you should check valve type and material compatibility. For example, some check valves are spring-loaded, using springs to control opening and closing. However, some check valves have a ball or disc to block backflow.

You should also check the check valve manufacturer‘s data sheet to determine whether the check valve has a pre-set cracking pressure. In fluid specification, you must check the viscosity, density, and flow rate. For instance, thicker fluids impart more pressure, and vice versa. Moreover, the fluid with a faster flow rate demands lower cracking pressure.

Step 2: Determine the Required Force

Once you know the check valve’s specifications, determine the force. This force allows fluid to impart pressure on the valve to open it. It is measured in Newton. If the required force is low, the check valve remains closed, and vice versa. So, this force should be strong enough to overcome the resistance of the spring.

It depends on two factors: The pressure of the fluid and the area of the valve opening. So, first, use a gauge to determine the pressure of the liquid. After that, measure the diameter of the valve opening. This diameter will give you a direct value for the area. When you have these two parameters, apply the following formula to measure force.

F= P × A

Step 3: Calculate the Effective Area

The effective area is the part of the valve where the fluid applies the pressure. In check valves, It is a door or opening point from where fluid passes. It is calculated in square inches or meters, depending on the valve size. If a valve has a large effective area, fluid needs to exert less pressure. However, a check valve with a small effective area requires more pressure to open it.

To calculate this area mathematically, apply the formula A=πr.

A= effective area

π= 3.14

r= Radius of valve opening ( Which is half of the diameter)

Step 4: Apply the Formula

Now that you have both the required force and effective area values, you just need to apply a simple formula. The formula for calculating cracking pressure on a check valve is:

P = F / A

P= Cracking pressure

F= Required Force

A= Effective Area

Let me simplify it with an example. Suppose the required force to open the check valve is 7 Newton. The value of the effective area is 2 square inches. Let’s put these values in the above formula.

P= 7/2 = 3.5 psi or bar

Quick Highlight: You can also calculate pressure cracking directly without mathematical calculations. For example, valve manufacturers often provide cracking pressure ratings on the labels. If not, you can calculate it by directly connecting a pressure gauge to the upstream side of a check valve.

Factors Affecting Cracking Pressure

Do you think check valve cracking pressure is a constant value? You are wrong! A tiny change in the valve’s environment drastically impacts the cracking pressure. Let’s discuss some factors that affect the cracking pressure of a check valve.

1- Valve Design

The design and physical appearance of the check valve highly affect the cracking pressure. HOW? For example, swing check valves have discs that can easily swing with a slight fluid force. Thus, these valves have lower cracking pressure. However, the cracking pressure varies with the ball’s weight in the check valve. Moreover, the size of the valve also affects the cracking pressure.

If the check valve is large, fluid will find more room to flow. As a result, it exerts low pressure, which directly decreases the cracking pressure. Lastly, check that the valve cracking pressure varies with the material. For instance, metal valves are heavier and difficult to open, requiring more pressure. On the other hand, plastic valves are lighter and have low cracking pressure.

2- Spring Strength

Spring strength is another factor that affects the cracking pressure. The spring is the key component that pushes the valve to shut down or open. When fluid exerts pressure on the valve, the spring contracts, allowing the disc to open and flow fluid. However, this only happens when the cracking pressure exceeds the spring strength.

So, if the check valve has a strong spring, the cracking pressure will be higher. In simple words, to push a strong spring aside, fluid needs more cracking pressure. However, if the spring is weaker, fluid requires less force to set it aside. As a result, cracking pressure is also reduced. Some check valves do not have springs at all; they rely on the gravity effect. These check valves have lower cracking pressure.

3- Fluid Type

The type of fluid passing through a check valve also influences cracking pressure. HOW? As you know, fluids are divided based on viscosity. Fluids with low viscosity are thin, and vice versa. So, when a low-viscosity or thin fluid passes through a check valve, it moves with less resistance. As a result, it passes quickly, and the cracking pressure decreases.

Conversely, if a viscous fluid passes through a valve, it moves slower. Therefore, a high force is required to ensure its smooth movement. As a result, cracking pressure increases. However, the cracking pressure is very low in compressed air and gas. They have low to zero viscosity and pass through the check valve more quickly.

4- Temperature and Pressure Conditions

Fluctuating temperature conditions highly affect the check valve cracking pressure. When a hot fluid passes through the check valve, it loses the spring and other components. As a result, the spring opens the valve disc more quickly, and fluid passes with less resistance. Less resistance means lower cracking pressure. The same is the case with external pressure.

The higher the external pressure, the lower the cracking pressure. Conversely, the spring becomes stiff when the fluid’s temperature is low. This doesn’t allow the fluid to pass quickly. Consequently, the fluid must exert more force, directly increasing the cracking pressure. Moreover, if the system’s pressure decreases, the cracking pressure increases.

5- Installation Position

Check valves can be installed in two positions: vertical and horizontal. Both of these positions affect the cracking pressure of a check valve. For example, gravity has no effect if the valve is installed horizontally. Only spring is there to resist the fluid. Therefore, fluid doesn’t require more force to pass, and cracking pressure decreases.

However, if the valve is installed vertically but the fluid flows upward, it moves against gravity. Now, along with the spring, the fluid has to face extra gravity resistance. Therefore, cracking pressure increases. The second case is when fluid flows downward. It moves with gravity. As a result, the resistance of gravity decreases, and fluid needs less force to pass. Thus, cracking pressure decreases.

Frequently Asked Questions

Can cracking pressure be adjusted?

Yes, the cracking pressure can be adjusted for some check valves. These valves have a spring-loaded mechanism that allows adjustment of tension. Tightening the spring can increase the resistance and cracking pressure.

What Happens If the Cracking Pressure Is Too High?

If the cracking pressure is too high, it causes pressure buildup. As a result, the valve will not open at all or too late. This causes system deterioration and affects the overall valve efficiency.

Can cracking pressure change over time?

Yes, cracking pressure changes over time due to external factors. When humidity occurs, springs tighten and resist fluid flow, increasing cracking pressure. However, when temperatures rise, springs become loose, reducing cracking pressure.

Conclusion

Check valve cracking pressure and the minimal force required to open the valve. This force is exerted by the fluid that passes through the valve. It plays a vital role in the smooth flow of the fluids. Moreover, the proper value of cracking pressure is crucial to running the system efficiently. For example, if the check valve cracking pressure is too low, it doesn’t open the valve.

However, the system will malfunction if the cracking pressure is too high. Therefore, before you install a check valve, calculate its pressure. You can calculate it using a gauge or by following the simple steps discussed in this article. Lastly, this pressure is also affected by external factors such as temperature, pressure, and type of valve and spring.