1. Introduction of Buried Butterfly Valves

Buried butterfly valves are unsung heroes of underground piping systems, delivering reliable flow control for municipal water supply, wastewater treatment, natural gas pipelines, and industrial applications. Engineered specifically for subterranean use, these valves combine durability, ease of operation, and low maintenance needs, making them a go to solution for challenging underground environments.

With their compact design, lightweight build, and rapid actuation, butterfly valves stand out as an efficient choice for buried installations. They thrive in tight spaces and areas with limited access, offering a streamlined approach to fluid management where traditional valves might fall short.

2. What Makes a Butterfly Valve “Buried”?

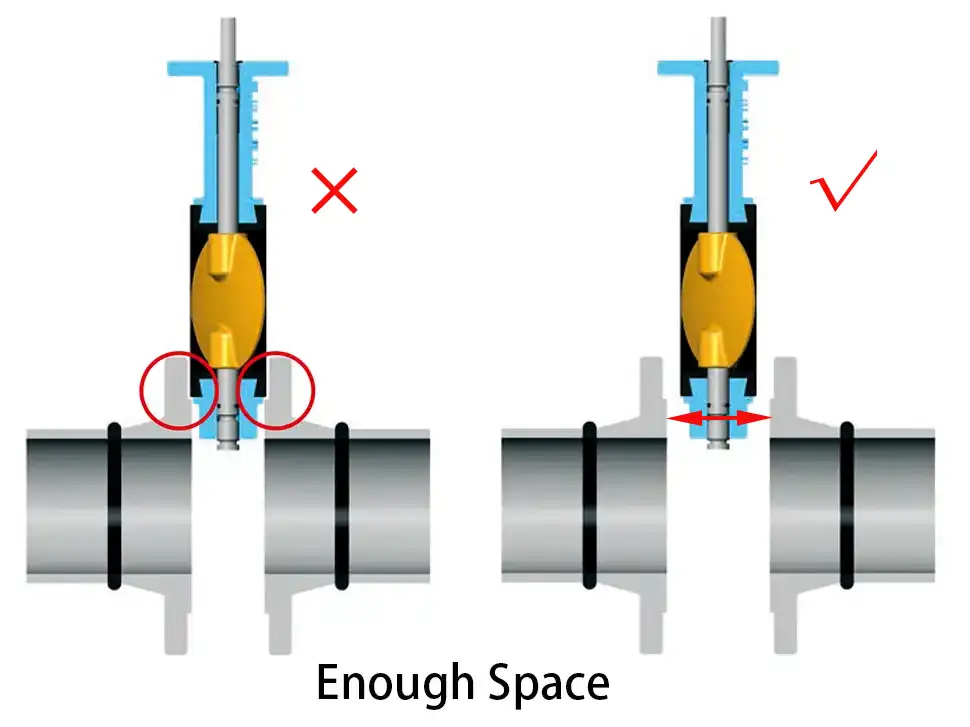

A buried butterfly valve is exactly what it sounds like—a butterfly valve installed below ground within a piping network. Unlike their above-ground counterparts, these valves are designed to withstand the rigors of underground conditions. They often feature extended stems or operators, allowing control from the surface without excavation. Durability is key, as accessibility for repairs or replacements is limited once they’re buried.

3. Design and Construction of Buried Butterfly Valves

Buried butterfly valves are built to last, with specialized features that ensure performance in harsh underground settings.

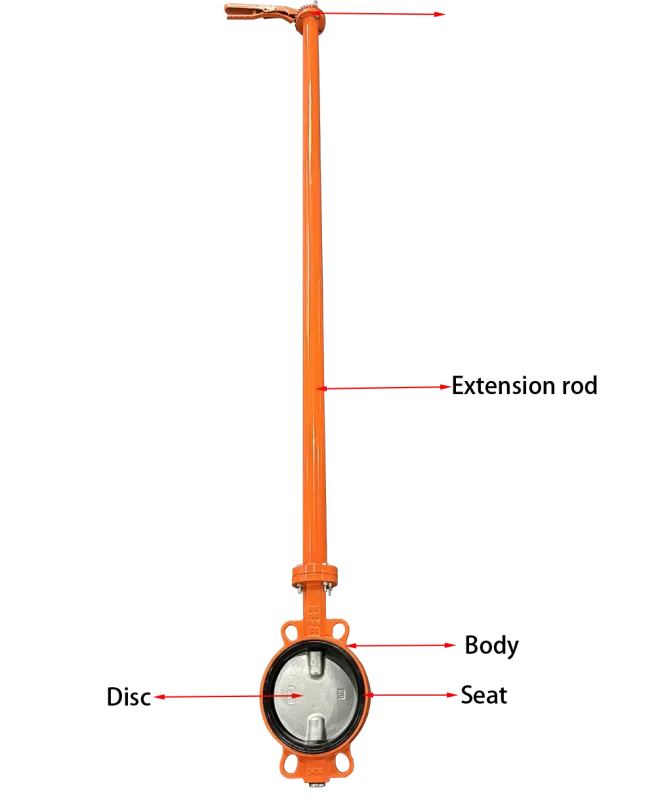

Here’s a closer look at their key components:

-Valve Body: Crafted from robust materials like ductile iron, cast iron, or stainless steel, the body resists corrosion in damp environments. Epoxy coatings or similar protective layers enhance longevity.

-Disc: Made from stainless steel, bronze, or coated metals, the disc regulates flow with minimal friction while ensuring a tight seal when closed.

-Seat: Typically constructed from elastomers like EPDM or PTFE, the seat provides excellent sealing and resists wear over time.

– Stem: Connecting the disc to the actuator, the stem is sealed with O-rings or packing to block soil and water intrusion.

-Drive: Extension rods, gear operators, or actuators (pneumatic, hydraulic, or electric) enable surface-level operation, often housed in protective enclosures.

– Protection Features: Fusion-bonded epoxy coatings, cathodic protection, and waterproof seals safeguard against corrosion and environmental damage.

4. Advantages of Buried Butterfly Valves

Why choose a buried butterfly valve? Here’s what sets them apart:

4.1 Benefits Over Other Valve Types

– Space-Saving: Their compact size beats bulky gate valves, ideal for cramped underground setups.

– Fast Operation: A simple quarter-turn adjusts flow in seconds.

– Large Diameters: Available up to DN3000, they handle big pipelines with ease.

– Lightweight: Easier to transport and install than heavier alternatives.

– Low Maintenance: Properly installed, they require minimal upkeep.

– Cost-Effective: Affordable upfront and over the long haul.

4.2 Edge Over Traditional Butterfly Valves

-Enhanced Durability: Protective coatings and tough materials extend lifespan underground.

-Space Efficiency: They don’t disrupt surface traffic or layouts while traditional butterfly valves need, perfect for urban water, gas, or sewage systems.

– Corrosion Resistance: Built to resist harsh conditions, reducing failures.

– Robust Design: Withstands pressure and vibration for reliable, long-term use.

– Maintenance-Free Focus: Wear-resistant bearings, thick seals, and waterproofing cut repair needs.

-Remote Operation: Extended rods or automated controls simplify surface adjustments.

-Environmental Protection: Sealed covers and waterproof stems prevent silt, water, or sewage infiltration.

5. How Does a Buried Butterfly Valve Work?

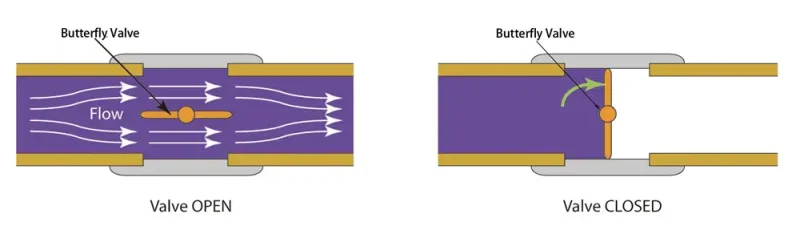

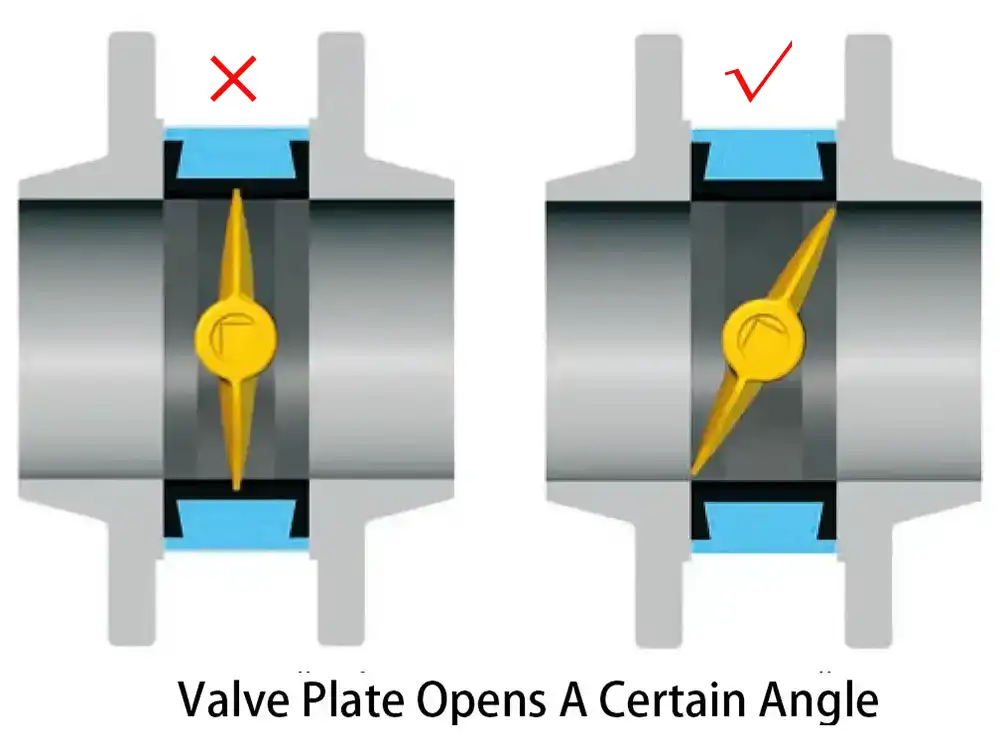

The mechanics are straightforward: a disc rotates 90 degrees to manage flow.

Fully open, it aligns with the pipe for unobstructed passage;

fully closed, it presses against the seat to stop flow completely.

For buried setups, operators use extension rods or gear systems from above ground.

In automated systems, actuators adjust the valve remotely, no hands-on intervention is required.

6. Applications of Buried Butterfly Valves

These versatile valves shine across industries:

-Municipal Water Supply: Controls drinking water distribution and emergency shutoffs.

– Wastewater Treatment: Manages sewage flow in underground networks.

– Gas Pipelines: Ensures safe, space-efficient transport of natural gas or oil.

-Industrial Processing: Handles chemicals and slurries in underground factory lines.

– Irrigation: Distributes water efficiently across large agricultural areas.

– Fire Protection: Powers underground fire mains for hydrants and sprinklers.

7. Installation and Maintenance Tips

Buried butterfly valves demand careful installation and upkeep to perform reliably over time.

7.1 Installation Steps

Site Prep: Excavate a trench to the correct depth.

– Valve Positioning: Align the valve with flanges or welds in the pipeline.

– Backfill: Use suitable materials to support and stabilize the valve.

– Operator Setup: Install extension stems or actuators for surface access.

– Testing: Pressure-test to confirm no leaks before final burial.

7.2 Maintenance Best Practices

– Routine Operation: Cycle the valve periodically to prevent sticking.

– Testing: Check flow and pressure regularly to catch issues early.

– Actuator Care: Inspect and lubricate remote operators as needed.

– Corrosion Checks: Monitor coatings for wear, especially in corrosive soils.

– Leak Detection: Investigate any signs of leakage promptly.

8. Conclusion

Buried butterfly valves may not grab headlines, but they’re vital to the seamless operation of underground piping systems. From water supply to gas lines, their compact design, easy operation, and rugged build make them a smart, cost-effective choice. Quietly working beneath the surface, these valves keep our infrastructure flowing smoothly-proof that great things often go unseen.