Single Flange Butterfly Valve Overview

Many butterfly valve types exist. One design stands out, though less known. The single flange butterfly valve plays a key role. This article covers its design, function, applications, advantages, and limitations in detail.

1. Definition of Single Flange Butterfly Valve.

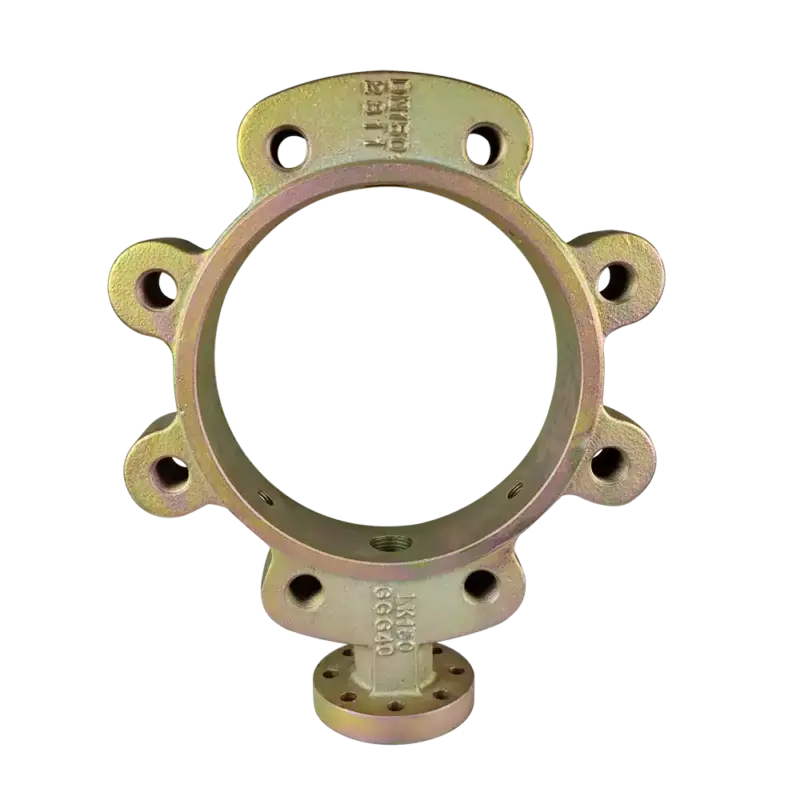

What is a single flange butterfly valve? It differs from wafer, double flange, or lug butterfly valves. It has one flange in the valve body’s center. This flange connects to a pipeline flange. Bolts secure the connection.

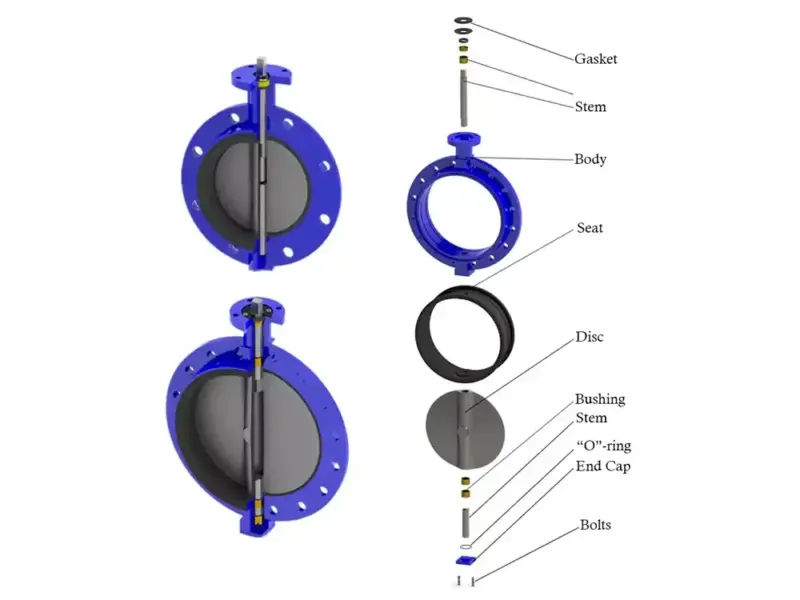

2. Core Components

-

Valve Body: The main structure. It holds all internal parts. Common materials include cast iron, stainless steel, or ductile iron.

-

Valve Disc: A round disc. It rotates to control fluid flow. It mounts on a shaft. It rotates 90 degrees from open to closed. Materials vary based on fluid corrosiveness and pressure. Options include stainless steel, aluminum bronze, or coated ductile iron.

-

Valve Seat: The sealing surface. It ensures a tight seal when closed. Elastomers like EPDM, nitrile rubber, or PTFE are used.

-

Valve Stem: A shaft. It links the disc to the actuator or handle. It transmits rotational force. Stainless steel is standard for strength and corrosion resistance.

-

Actuator: Drives disc rotation. Options include manual, pneumatic, or electric. Manual suits small valves or infrequent use. Automated actuators fit large valves or precise control needs.

3. Working Principle

The single flange design affects only installation and connection. It doesn’t change the core operation. The valve works simply. When fully open, the disc aligns with the flow. This minimizes resistance. It allows maximum fluid passage. When closed, the disc sits perpendicular to the flow. It seals tightly with the seat.

4. Advantages of Single Flange Butterfly Valve.

4.1 Cost-Effectiveness

The single flange uses less material than double flange or lug valves. This cuts manufacturing costs. It also lowers transport costs. It’s ideal for budget-limited projects.

4.2 Easy Installation

Like wafer valves, it bolts to the pipe flange. It clamps in place. This reduces installation time.

4.3 Low Maintenance

Its simple design has few moving parts. This reduces wear. It lowers maintenance needs. It extends service life.

4.4 Energy Efficiency

The disc’s streamlined design handles pressure well. It minimizes pressure drop when open. This saves energy in pumping systems.

5. Limitations

5.1 Limited Size Range

Single flange valves complement wafer valves. Their size range is DN700-DN1000. For larger diameters or tight spaces, choose U-type valves (up to DN1800).

5.2 Limited Pressure Range

As a midline butterfly valve, it’s not suited for extreme pressure or temperature. The elastomer seat limits performance.

5.3 Not Suitable for Abrasive Media

Abrasive fluids or mud wear the disc and seat. This shortens valve life.

6. Comparison with Other Valve Types

Comparing helps understand single flange valves better.

6.1 Wafer Butterfly Valve

It has no flanges. It sits between two pipe flanges. It’s lighter and cheaper. Its maximum size is DN600.

6.2 Double Flange Butterfly Valve

It has flanges on both sides. This adds stability. It suits high-pressure systems. But it’s heavier and costlier.

6.3 Lug Butterfly Valve

It has threaded lugs. These allow easy removal without pipeline disruption. It can serve at pipeline ends. It’s more flexible but pricier than single flange valves.

Single flange valves balance cost, ease of installation, and application fit. They’re ideal for specific scenarios.

7. Applications of Single Flange Butterfly Valve.

The valve’s quarter-turn (0 to 90 degrees) enables fast opening and closing. This suits applications needing quick response.

7.1 Water and Sewage Treatment

In water treatment plants, these valves regulate raw water, treated water, or sludge. Their compact design fits water pipes. Reliable sealing ensures performance. Corrosion-resistant materials add durability in wet environments.

7.2 HVAC Systems

Heating, ventilation, and air conditioning systems use these valves. They control cold or hot water flow. The single flange design eases installation in tight spaces. Low pressure drop boosts energy efficiency.

7.3 Chemical and Petrochemical Industry

For mildly corrosive fluids or gases, these valves excel. Stainless steel or PTFE components handle corrosion. Tight sealing prevents leaks in chemical plants.

7.1 Food and Beverage Processing

In food-grade applications, hygienic materials are used. These valves control liquids like milk, juice, or syrup. Surface treatments ensure cleanliness. Zfavalve’s rubber seats hold WRAS certification.

7.5 Power Generation

In power plants, these valves manage cooling water, steam, or fuel. Their robust build handles high pressure and temperature.