ZFA Types of AWWA C504 Butterfly Valve

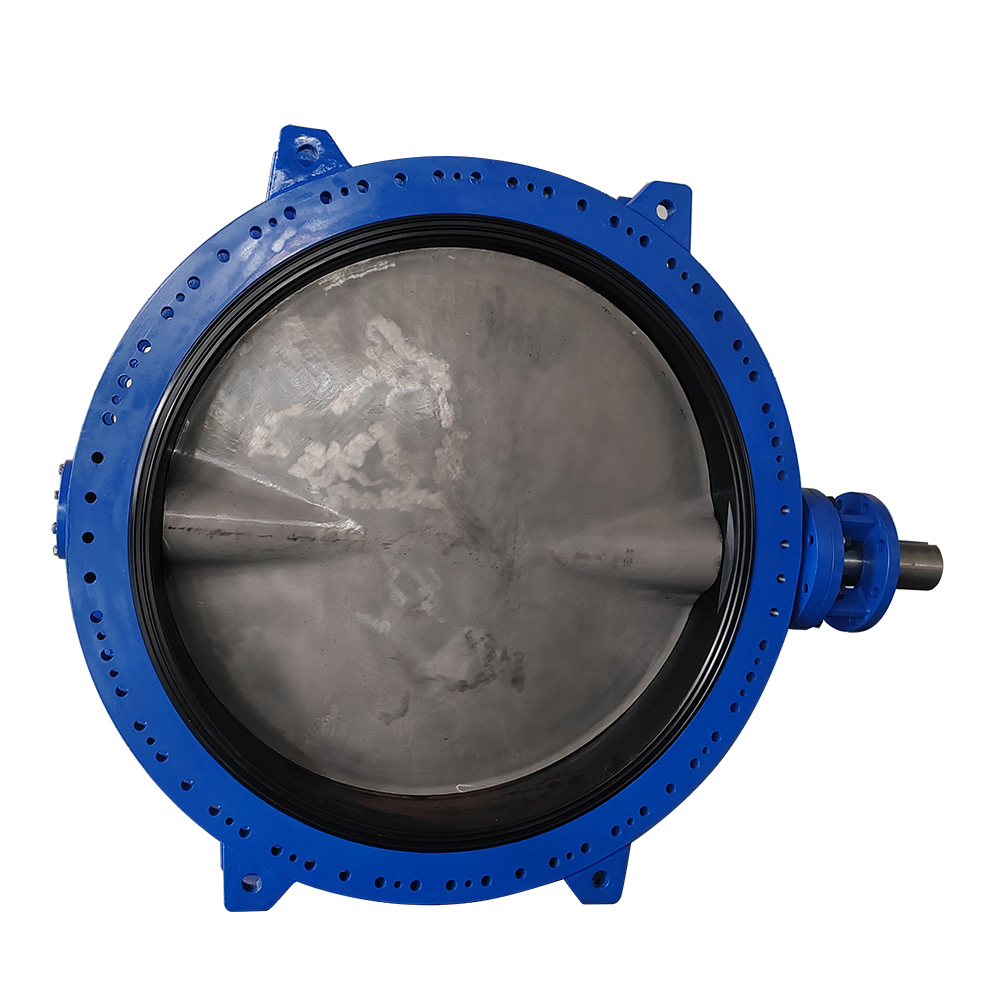

AWWA C504 Concentric Flanged Butterfly Valve

Connection: Double flanged

DN: 2”-120”

PN/Class: PN6-PN16/CL125-CL150

Temperature: -10 to 120 centigrade.

Flange Standard: ANSI B16.1

Top Flange Standard: ISO 5211

Design/FTF/Pressure Test: AWWA C504

More InformationAWWA C504 Double Offset Flanged Butterfly Valve

Connection: Double flanged

DN: 2”-120”

PN/Class: PN6-PN40/CL125-CL150

Temperature: -10 to 120 centigrade.

Flange Standard: ANSI B16.1

Top Flange Standard: ISO 5211

Design/FTF/Pressure Test: AWWA C504

More InformationWhat is Awwa C504

The AWWA C504 Butterfly Valve is a valve designed and manufactured in accordance with the standards established by the American Water Association (AWWA). Such valves are widely used in water treatment, water supply and drainage, industrial fluid control and other fields.

They are usually made of wear-resistant materials:

Body: ductile iron, carbon steel/WCB, or stainless steel

Seats: elastic sealing materials like rubber (EPDM. NBR, Silicon Rubber, FPM).

As you know, the price of AWWA C504 butterfly valve requires relatively complex combination calculation, so if you have any questions, please contact us, we are always here.

Why Choose US

ABOUT US

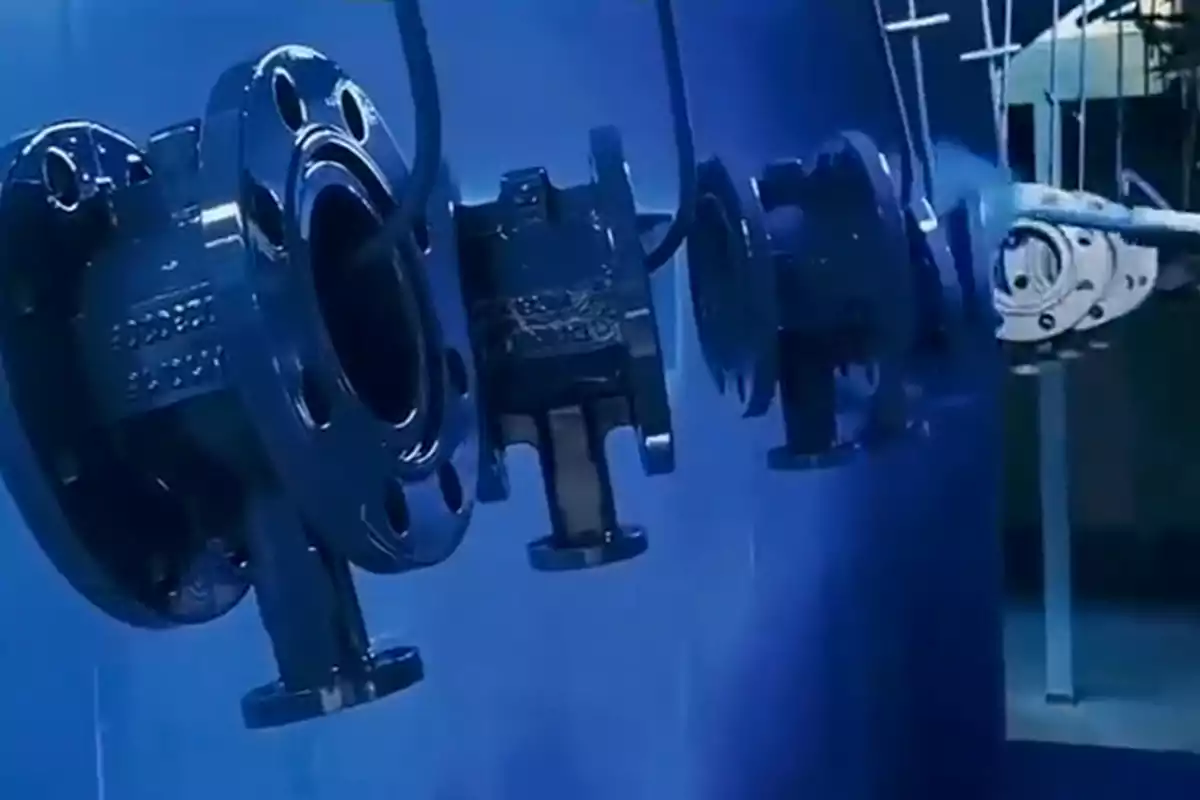

ZFA VALVE factory Founded in 2006, mainly produce butterfly valves, valve parts which compliance with valve international standard.

We have got ISO, CE, Wras certificates etc.

OEM Capacity

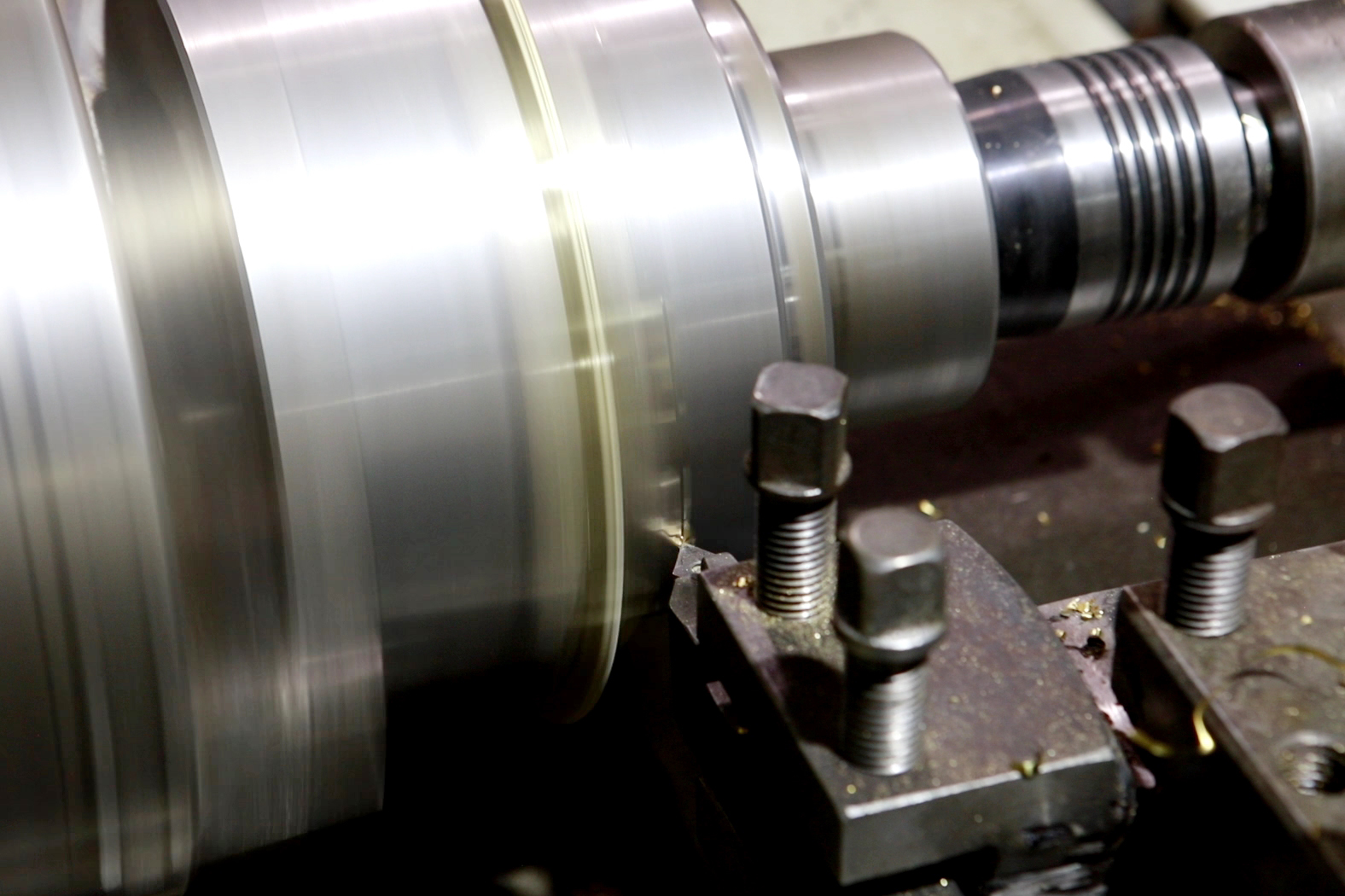

We have 32 machines (include CNC, machine center, semi-auto machine, pressure testing machine, etc.)

The most important is that we have tens of molds in hand, such as valve body, disc, handle molds.

Butterfly Valve Manufacturing Process

We’re a real Awwa C504 butterfly valve factory with 17 years production experience, OEM for some customers around the world. All butterfly valves sold by ZFA VALVE are manufactured in our own factory. The excellent quality of our products comes from the meticulous management of the production process. ZFA VALVE is proud to show you our real production scene. Here is our motto: Rigorous production leads to excellent quality!

Step 1: Casting

Step 2:Material Preparation

Step 3:Material Quality Inspection

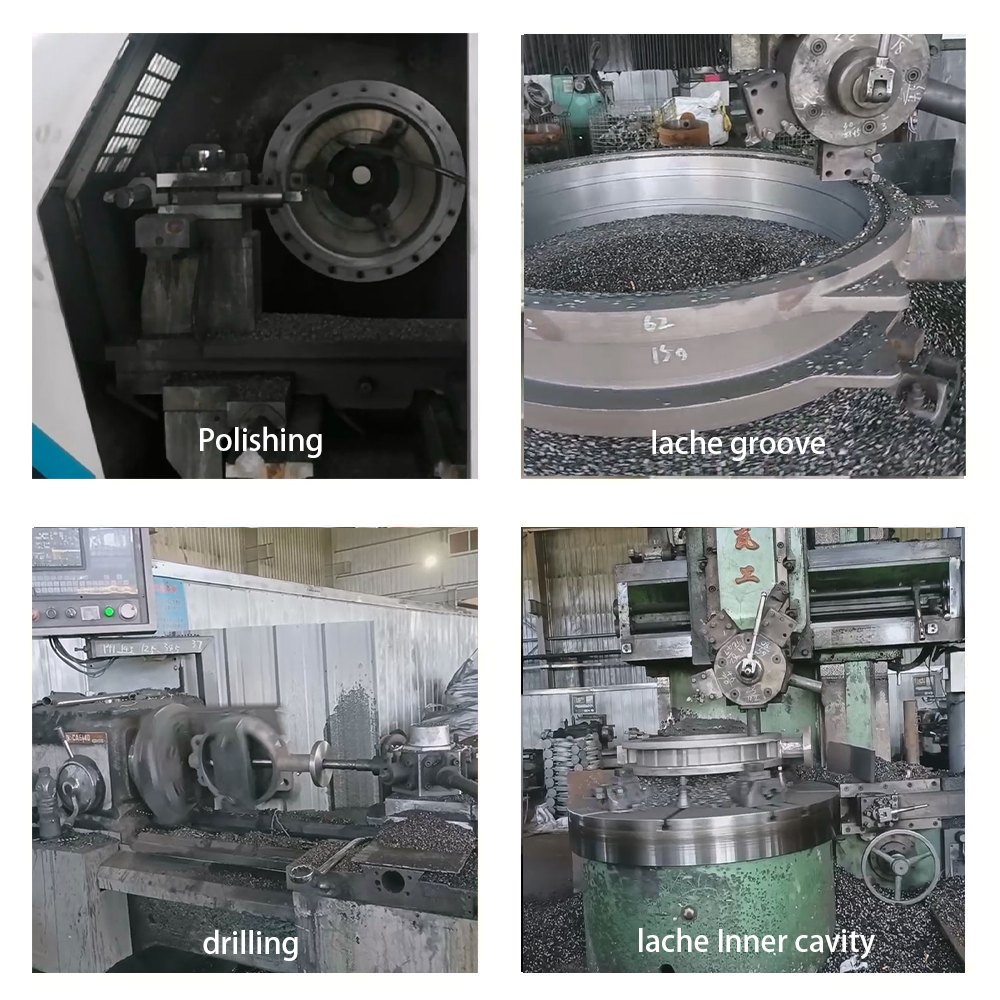

Step 4:Machining Parts

Step 5:Surface Treatment

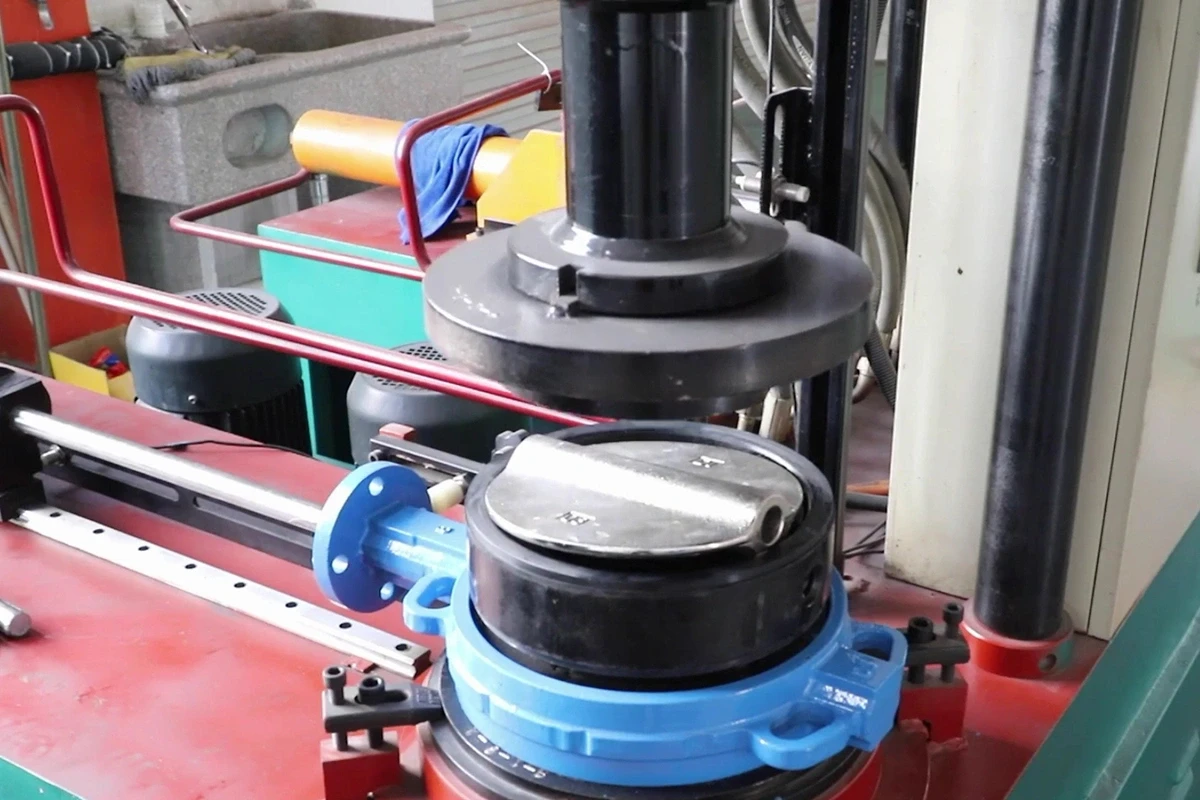

Step 6:Assembly

Step 7:Inspection And Quality Control

Step 8: Packaging

Step 9: Distribution

Producing Process of Butterfly Valve Parts

Valve Body of Butterfly Valve

Valve Disc of Butterfly Valve

Soft-backed Seat of Butterfly Valve

Factory Overview

Get More Videos about MANUFACTURING PROCESS, and CAD DAWING about the butterfly valve, please contact us!

Certificates

Valve General Knowledge

FAQ

1.What is the Face to face dimensions?

A:

| FACE TO FACE lengths for flanged and wafer valves and minimum body shell thicknesses for all body types | |||||||||||||||

| FACE TO FACE * | Minimum Body Shell Thickness | ||||||||||||||

| Valve Size | Short Body | Long Body | Wafer | Class 25A | Class 75A | Class 150A Class 150B Class 250B |

Class 250B | ||||||||

| Class 25B | Class 75B | Ductile Iron | Gray Iron | ||||||||||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm |

| 3 | 75 | 5 | 127 | 5 | 127 | 2 | 50.8 | 0.37 | 9.4 | 0.37 | 9.4 | 0.37 | 9.4 | 3/8 | 9.5 |

| 4 | 100 | 5 | 127 | 7 | 178 | 2-1/4 | 57.2 | 0.4 | 10.2 | 0.4 | 10.2 | 0.4 | 10.2 | 15/32 | 11.9 |

| 6 | 150 | 5 | 127 | 8 | 203 | 2-13/16 | 71.4 | 0.43 | 10.9 | 0.43 | 10.9 | 0.43 | 10.9 | 5/8 | 15.9 |

| 8 | 200 | 6 | 152 | 8-1/2 | 216 | 2-15/16 | 74.6 | 0.46 | 11.7 | 0.46 | 11.7 | 0.46 | 11.7 | 5/8 | 15.9 |

| 10 | 250 | 8 | 203 | 15 | 381 | 3-1/8 | 79.4 | 0.5 | 12.7 | 0.5 | 12.7 | 0.54 | 13.7 | 11/16 | 17.5 |

| 12 | 300 | 8 | 203 | 15 | 381 | 3-3/8 | 85.7 | 0.54 | 13.7 | 0.54 | 13.7 | 0.58 | 14.7 | 3/4 | 19.1 |

| 14 | 350 | 8 | 203 | 16 | 406 | 3-3/4 | 96.3 | 0.54 | 13.7 | 0.58 | 14.7 | 0.63 | 16 | 7/8 | 22.2 |

| 16 | 400 | 8 | 203 | 16 | 406 | 4-1/8 | 105 | 0.58 | 14.7 | 0.63 | 16 | 0.68 | 17.3 | 1 | 25.4 |

| 18 | 450 | 8 | 203 | 16 | 406 | 4-5/8 | 117 | 0.63 | 16 | 0.68 | 17.3 | 0.79 | 20.1 | 1-1/8 | 28.6 |

| 20 | 500 | 8 | 203 | 18 | 457 | 5-1/8 | 130 | 0.66 | 16.8 | 0.71 | 18 | 0.83 | 21.1 | 1-1/8 | 28.6 |

| 24 | 600 | 8 | 203 | 18 | 457 | 0.74 | 18.8 | 0.8 | 20.3 | 0.93 | 23.6 | 1-1/4 | 31.8 | ||

| 30 | 750 | 12 | 305 | 22 | 559 | 0.87 | 22.1 | 0.94 | 23.9 | 1.1 | 27.9 | 1-3/4 | 44.5 | ||

| 36 | 900 | 12 | 305 | 22 | 559 | 0.97 | 24.6 | 1.13 | 28.7 | 1.22 | 31 | 1-7/8 | 47.6 | ||

| 42 | 1050 | 12 | 305 | 24 | 610 | 1.07 | 27.2 | 1.16 | 29.5 | 1.35 | 34.3 | 2-1/4 | 57.2 | ||

| 48 | 1200 | 15 | 381 | 26 | 660 | 1.18 | 29.9 | 1.37 | 34.8 | 1.48 | 37.6 | 2-1/2 | 63.5 | ||

| 54 | 1350 | 15 | 381 | 28 | 711 | 1.3 | 33 | 1.51 | 38.4 | 1.63 | 41.4 | ||||

| 60 | 1500 | 15 | 381 | 30 | 762 | 1.39 | 35.3 | 1.62 | 41.1 | 1.89 | 48 | ||||

| 66 | 1650 | 18 | 457 | 34 | 864 | 1.625 | 41.3 | 1.8 | 45.7 | 2 | 50.8 | ||||

| 72 | 1800 | 18 | 457 | 36 | 914 | 1.75 | 44.5 | 2 | 50.8 | 2.375 | 60.3 | ||||

2. What is function of butterfly valve?

A: Butterfly valve is also called ON-OFF valve, it is used for flow control: start and stop the fluid.

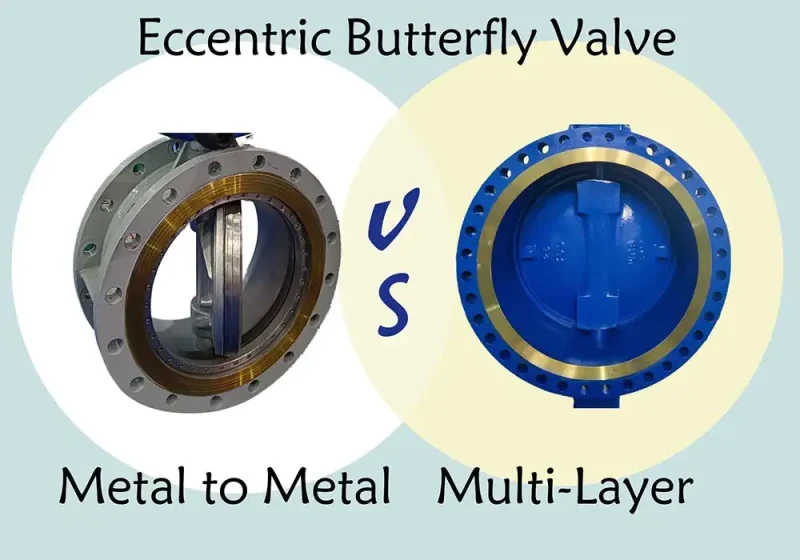

3. What is working principle of double eccentric butterfly valve?

A: When the sealing surface is closed, friction occurs between the disc and the valve seat, and the sealing effect is very good. It has the characteristics of small area and strong pressure. After the valve is opened, the butterfly plate can quickly separate from the valve seat, which greatly eliminates unnecessary excessive extrusion and scratching between the butterfly plate and the valve seat, reduces the opening resistance, reduces wear, and increases the service life of the valve seat.

4. What is working principle of triple eccentric butterfly valve?

A: Due to the effect of the eccentric shaft, when it is close completely, the butterfly plate moves a certain distance into the sealing cone surface of the valve seat, and the sealing surface of the butterfly plate and the valve seat matches to achieve reliable sealing performance. It makes up for the contradiction that hard seals which also named metal to metal seal have poor sealing, while soft seals have good sealing effects but are not resistant to high temperatures.

5. What is the connection method of the offset butterfly valve?

A: All wafer, double flange, and lug end are suitable for the eccentric bfv valve.

6. What is the actuator of the eccentric butterfly valve?

A: Worm Gear, Electric, and Pneumatic can be selectable.

7. Can you casting our Logo on the Valve body?

A: Yes, we provide OEM service, you can design your Logo and packing etc.