When it comes to controlling the flow of fluids, gate valves stand out as a reliable solution. However, they come in several types, each specific in its usability. Understanding those types and working is crucial for better flow control. That’s why I am writing a complete guide to gate valves and their types.

Selecting the wrong gate valve type will do more harm than good. Despite their wide usability, many people are unfamiliar with gate valve types. If you are one of those, fret not! In this article, we will discuss gate valves and their popular types. So, let’s get started!

Overview of Gate Valve

Before discussing gate valve types, let’s first look at their overview.

A gate valve is a type of valve that stops or starts fluid or gas flow in a pipeline. It has a gate inside its body, which is why it is named a gate valve. When that gate lowers, it stops the flow of liquid. However, when the gate lifts, it allows the fluid to pass. It functions to open or close the fluid passage.

Simply put, these valves do not regulate the flow but have an on/off control system. This means they will allow the fluid to pass or completely block it. Gate valves also do not control the speed at which the fluid will flow. Gate valves are known for their durability and strength.

Hence, they are mainly used in industrial setting systems to provide tight seals. Gate valves do not work alone but have a series of components that work together. Here is the list of those components:

- Seat

- Stem

- Body

- Gland

- Bonnet

- Packing

- Gate/disc

- Handwheel

These parts of the gate valve work together to ensure proper operation. Any part of the gate malfunctions can result in gate valve failure. Gate valves are widely used across many industries. Remember, their job is not to regulate the flow but to allow and stop it in different applications.

Basic Working of a Gate Valve

In another article, I discussed the complete working principle of gate valves. You must check that out if you’re a total newbie. Let’s have a bird’ s-eye view of their workings before discussing the types of gate valves.

The gate valve works like a door inside a pipe. It has simple closing and opening mechanisms. You need to open the gate valve when you want to allow fluid to flow. This process starts when you turn on the handwheel, which is usually present on the top of the valve.

As you turn it anticlockwise, it rotates the stem (connection between the gate and handwheel). This rotation causes the stem to move upward. As the stem moves upward, it pulls the gate upward. Once this gate is lifted, there is no hindrance inside the valve. Thus, fluid can freely flow through the valve without any block.

You must close the valve when you want to stop the fluid flow. For this purpose, you turn the handwheel clockwise. As a result, the stem rotates and moves downward. This stem pushes the gate in a downward position, too.

As the gate comes down, it reduces the free space inside the valve. When the gate completely reaches the bottom, it presses against the valve seat. As a result, there is no free space for fluid to pass. This blocks the fluid, and the mechanism is called the closing of the gate valve.

Types of Gate Valves

I hope you have an idea of how gate valves work and what the basics of gate valves are. However, these gate valves vary in design, material, and operation method, leading to different types. Let’s briefly explain those types in this section.

1- Parallel Slide Gate Valve

It is a special gate valve type with two flat gate pieces called “discs.” These discs slide upward when you open the valve. However, when you close the valve, it slides downward to block the fluid. The word parallel means the gate piece or discs are straight or flat, not wedges or angles.

However, these valves use springs or fluid pressure to block the fluid. This non-wedging action causes less wear and tear. Moreover, they can handle high pressure easily. Thus, parallel slide gate valves are mainly used in boilers, steam lines, and power plants.

2- Solid Wedge Gate Valve

It is the most common type of gate valve. The name “wedge” is after the shape of the gate. These valves have a solid, one-piece metal wedge gate that is thicker at the bottom. This gate has a slightly angled or flat shape. You can imagine it like the doorstep of a door.

When the wedge gate moves up, it allows the fluid to pass. However, it completely blocks the flow when it is in a lower position. Due to its simple design, these valves are easy to install and maintain. Therefore, they are mainly used in the water supply system and oil and gas lines.

3- Flexible Wedge Gate Valve

A flexible wedge gate is almost similar to a solid wedge gate. However, the big difference lies in the gate’s grooves and cuts in the middle. These grooves enhance the gate’s flexibility and allow it to adjust to high temperatures and pressures. For example, sometimes, the internal temperature of the valve becomes high.

This causes the metal parts to expand. If the gate is too stiff, it may press too hard and get stuck. However, in the flexible wedges, grooves allow the sides of the gate to move slightly and adjust to changes. Therefore, these valves have a long lifespan and are used for steam and hot water pipeline systems.

4- Split Wedge Gate Valve

It is another type of gate valve in which the gate is split into two parts. These two halves are shaped like a half-disc and connected by special spacers or springs. This design allows both parts of the gate to tilt or move independently. When you open the valves, these halves lift upward, allowing the fluid to flow.

When the valve is closed, the two halves come downward and set on the valve bed. In case the surface of the valve bed gets uneven or worn out, these two halves can adjust themselves. For example, they move separately and press tight to close the opening. Due to this benefit, split gate valves are ideal for temperature fluctuation applications. They are used in gas pipelines and steam systems.

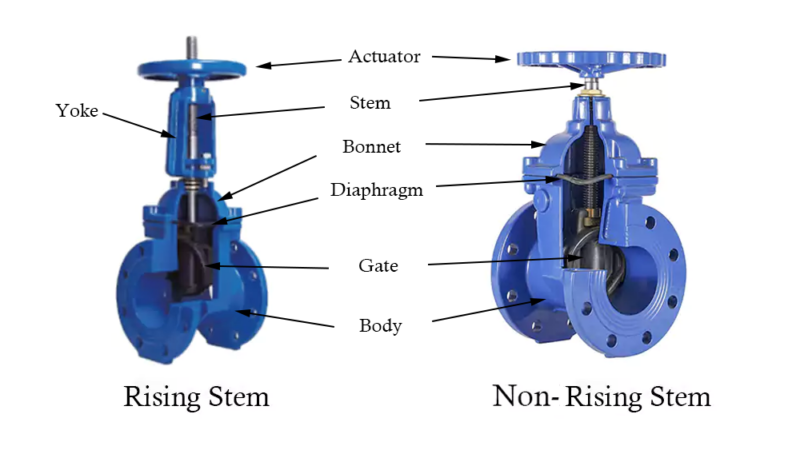

5- Rising Stem Gate Valve

The term ” rising stem” comes from how the stem behaves when a valve is operated. As I said above, the stem is connected with the gate and handwheel. When you turn the handwheel to open the valve, this stem rises. As a result, the gate also rises and allows the fluid to pass. However, this stem goes down on closing, blocking the fluid flow.

What is special about this type is that you can see if the valve is open or closed due to stem movement. When the stem is hidden, the valve is closed; when it is visible, it means the valve is opened. This design of a rising stem gate makes it easier to repair a gate valve. Thus, these valves are commonly used in fire protection systems and industrial plants.

8- Non-Rising Stem Gate Valve

A non-rising stem gate valve is the opposite type of a rising stem gate valve. In this type, the stem does not move up or down. Instead, it stays in place, and only the gate moves up and down to block or allow the fluid. However, you must wonder: how does the gate move? Actually, when you turn the handwheel, the steam rotates.

This stream has threads at its lower part. These threads help move the gate up and down. However, from the outside, the stem looks like it is standing, which is why it is called a non-rising stem gate valve. The primary benefit of this valve is that it takes up less vertical space. That’s why gate valve manufacturers recommend it for compact areas.

6- Knife Gate Valve

As the name suggests, this gate valve has a sharp-edged gate like a knife. So, how does this gate valve work? These valves are specially designed for thick fluids such as slurry and mud. When you open the valve, the knife gate moves upward, allowing the liquid to flow.

However, upon closing, this gate cuts through the fluid like a knife and blocks it. This sharp-cut motion of the gate makes this type different from other gate valves. Moreover, these valves are made with robust material to handle those thick materials. Hence, they are primarily used in the paper industry, water waste plants, and mining.

7- Flanged Gate Valve

This type of gate valve has flanges on both sides. Flanges mean a flat rim with holes. This gate valve design makes it easy to connect with pipelines. How? You place the valve between flanged pipes. The flanges of the gate valves are fixed with pipe, and you can tighten the valve using bolts. Often, a gasket is placed between them to prevent any leakage.

However, the flanges do not affect the working of these valves. This just changes how the valve connects to the pipes. They work the same as other gate valves. For example, a fledge valve uses a gate that moves up and allows the fluid to pass through. When you close the valve, fate comes down and blocks the fluid.

9- Hydraulic Gate Valve

Hydraulic gate valves operate using hydraulic pressure. This means they use hydraulic fluid to open and close the gate. How? They have a hydraulic actuator like a piston or cylinder. When hydraulic fluid passes through the actuator, it exerts pressure on the gate inside the valve.

As a result, it moves upward or downward to allow or block the fluid. This type of valve does not demand manual effort; the hydraulic fluid works for you. Therefore, these valves prove helpful in high-pressure pipelines. Lastly, hydraulic valves are easy to operate and can be controlled from a distance.

10- Electric Actuated Gate Valve

This type of gate valve uses an automated system. Instead of a manual handwheel, it uses electric power to open or close the valve. The valve is connected to an electric motor. When you turn on the motor, it rotates the stem. As the stem rotates, it raises or lowers the gate.

As a result, valves allow or block the fluid. This automated system proves helpful when the valve is too big or hard. Moreover, it also helps you control the valve precisely. However, these valves can increase the overall electricity bill. So they also come at higher prices.

Maintenance of Gate Valves

Gate valves are undoubtedly strong and reliable, but they need proper care to operate. Without maintenance, these valves get damaged and cause leakage. This can result in financial loss and serious hazards. So, how would you maintain a gate valve/ here are some simple tips for you!

- First, regularly inspect the gate valve. For example, look for leakage and immediately replace the valve if you notice any water oil. Moreover, check for rust and corrosion and prevent scaling on gate valves by coating.

- Dust and grease can make it difficult for the valve to move. That’s why you should clean the gate valve regularly. For example, wipe out the dust and oil buildup with detergent. If possible, flush the inside of the pipeline, too.

- As you know, the stem rotates continuously. If it gets stuck, the valve becomes hard to move. Therefore, you should apply lubricants such as grease to the stem. However, prevent over lubrication.

- Over time, the gate valve’s nuts and bolts become loose due to vibration. This can cause leakage and damage to the valve parts. Thus, check the external bolts and flanges. If they are loose, tighten them immediately.

- If the valve is old, some of its parts wear out with time. For example, sometimes, the gate gets scratched or bent. If you see such worn-out parts, replace them quickly.

Conclusion

A gate valve is a special type of valve that controls fluid flow in several industries. These valves operate by closing and opening. They have a gate and stem inside. When you turn the handwheel, the stem rotates and moves the gate. When the gate rises upward, it allows the fluid to pass.

However, when the gate lowers, it sets against the valve bed and blocks the fluid flow. Gate valves come in various types, each with a different specification. For example, some vary based on stem movement, and some differ in valve design. In this article, I have explored those types in detail. Lastly, maintaining the gate valve is crucial to ensure its smooth operation.