Introduction to butterfly valve leakage rate

Butterfly valves are ubiquitous in various industries, providing effective flow control in pipelines. An important aspect of their performance is their leakage rate, which determines how well they prevent fluid leakage when closed. This article takes an in-depth look at the complexity of butterfly valve leakage rates, exploring the factors that affect leakage rates, measurement methods, ways to reduce leakage rates, and their significance in different applications.

There are two types of leaking butterfly valves: those that meet normal standards and those that fail in production operations, in other words, congenital and acquired.

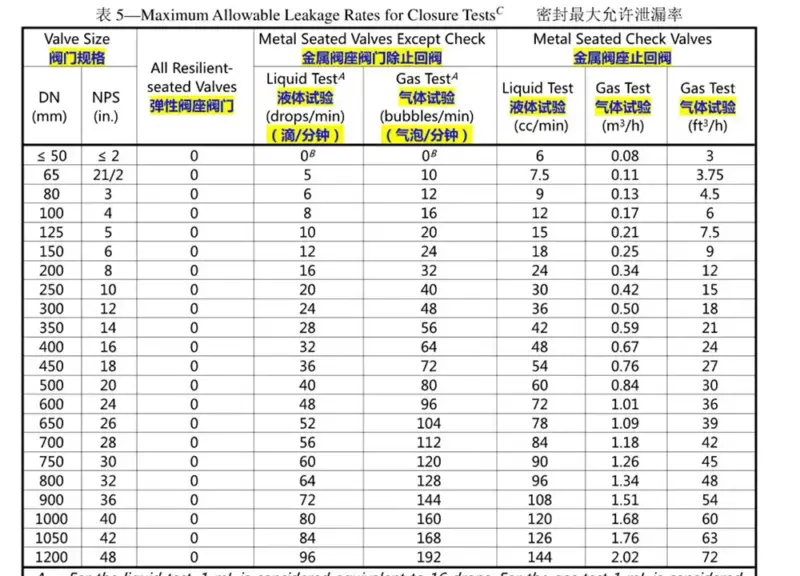

First of all, we must accept the concept that meeting standards does not mean that there is no liquid or gas escaping at all. The following table shows the leakage standards of API598. It can be seen that the leakage rate of soft seal butterfly valves, liquid seals and gas seals is 0, while butterfly valves with metal valve seats, such as the commonly used DN100, are allowed to perform liquid tests every time under the condition of reaching the test pressure. 8 drops flow out per minute, and the gas experiment allows 16 bubbles to escape per minute.

One, Factors affecting butterfly valve leakage rates:

1. Congenital.

a) Design of butterfly valve:

The design of a butterfly valve has a great impact on its leakage rate. Factors such as seal type, disc configuration and valve body construction play a vital role. The above-mentioned soft seal and metal seal are the effects of sealing mechanism design on leakage rate. Whether it is a soft seal, a metal-to-metal seal, or a combination seal, all affects its leakage characteristics.

Usually soft seals refer to centerline butterfly valves and double eccentric butterfly valves. Triple eccentric butterfly valves are divided into full metal seals and multi-layer seals, of which multi-layer seals can achieve zero leakage.

Soft seals such as EPDM or nitrile provide good sealing properties but may degrade over time, affecting leak rates.

b) Butterfly valve material

The material of a butterfly valve is one of the important factors that determines its leakage rate and durability.

Common butterfly valve body materials include ductile iron, cast stainless steel, WCB, forged steel, aluminum alloy, etc. Butterfly valves made of different materials have different corrosion resistance, wear resistance and sealing performance during use, which directly affects their leakage rate.

Stainless steel is recognized as a metal valve body material with excellent corrosion resistance and is suitable for various corrosive media. Its surface is smooth with fewer pores and blisters, so the leakage rate is lower.

Ductile iron is the most commonly used material for butterfly valves, and 80% of butterfly valves on the market are made of ductile iron. Because the price of ductile iron is relatively low, its corrosion resistance and sealing performance are good, and leakage problems are less likely to occur.

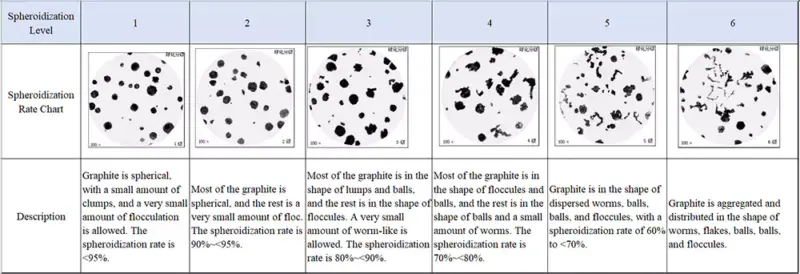

Of course, different butterfly valve manufacturers provide different quality materials for ductile iron butterfly valves. For ductile iron butterfly valves, the spheroidization rate is a very critical factor. The so-called spheroidization rate refers to the comprehensive index of the spheroidization degree of all graphite within a specified field of view. It reflects the degree to which all graphite within the field of view is nearly spherical. The mechanical properties of ductile iron are largely determined by the nodularity rate. Generally speaking, when other conditions are the same, the higher the spheroidization rate, the higher the mechanical properties. ZFA valve’s butterfly valve is recognized by customers as a butterfly valve with a very good spheroidization rate.

- WCB butterfly valve: WCB butterfly valve has better corrosion resistance under certain environmental conditions, but its leakage rate is slightly higher compared to stainless steel butterfly valves.

The carbon content of cast steel is different from that of 304 (carbon content WCB>304). The higher the carbon content, the greater the hardness; the lower the carbon content, the more corrosion-resistant. Therefore, the anti-corrosion performance of WCB is not as good as 304.

- Aluminum alloy butterfly valve: lightweight and has good corrosion resistance, because aluminum will naturally form a protective oxide layer when exposed to the air, which helps resist corrosion.

- Forged steel butterfly valve: Forged steel is deformed by heating the steel to a certain temperature and then forging it. During this process, the spacing between material particles is reduced, the grains are refined, and a strong forging structure is formed, thereby improving the strength of the material, reducing the occurrence of blisters, and thereby increasing corrosion resistance.

Commonly used grades of forged steel butterfly valves are A105, F304, F304L, F316, F316L.

c) Size and pressure level design:

The relationship between leakage rate and pressure is an objective law. Larger valves with higher pressure ratings may exhibit different leakage characteristics compared to smaller valves. Higher pressure exerts greater force on the sealing element. Therefore, for medium and high pressure media, a sealing design with high pressure resistance and resistance to deformation is required.

2. Acquired.

d) Conditions of use:

Factors such as the butterfly valve’s ambient temperature, medium temperature and pressure, and medium properties all affect the sealing performance of the butterfly valve. Extreme temperatures and high pressures can affect the flexibility and elasticity of sealing materials, resulting in increased leakage rates.

The greater the density of the medium, that is, the more viscous the medium is, the less likely it is to leak. However, if there are hard particles in the medium, the valve seat will be worn when the medium circulates and is opened and closed, which will also increase leakage.

e) Frequency of use:

The more times the butterfly valve opens and closes, the easier it is to cause wear to the sealing elements, leading to an increase in the leakage rate.

Two. Measurement methods of butterfly valve leakage rates:

For the leakage rate of butterfly valves, liquid and gas sealing tests can be used to test.

- Liquid Test: Evaluate the leakage rate by pressurizing the butterfly valve with the specified fluid and measuring any leakage through the closed butterfly valve. This is also the most common method for valve seal testing.

- Air tightness test: Completely immerse the closed butterfly valve in water, and add air at the design pressure to the butterfly valve. Any bubbles escaping from the butterfly valve indicate the presence of a leak, and the size and frequency of the bubbles are related to the leak rate.

Three. How to reduce the leakage rate of butterfly valve

The leakage rate is just a parameter. The purpose of figuring out the cause of the leakage is to reduce the leakage rate.

- Based on the innate conditions of the butterfly valve, select the structure, valve body, valve plate and valve seat materials suitable for the medium to ensure that it has good corrosion resistance and sealing performance.

- Regarding the possibility of the butterfly valve becoming unfastened, regular maintenance and inspection of the butterfly valve is required to detect and deal with leakage problems in a timely manner to ensure the normal operation of the butterfly valve.

Four. Meaning in different applications:

Industrial applications:

In industries such as chemical processing, oil and gas, and pharmaceuticals, leaking valves can cause serious production line safety, environmental safety, and personal safety issues. Therefore, butterfly valves with low leakage rates are essential for strict control of fluid flow.

Water treatment:

Butterfly valves are used to control the flow of water in municipal water systems where they are most commonly used. Low leakage rates prevent waste and ensure efficient distribution of water resources.

HVAC system:

Heating, ventilation, and air conditioning (HVAC) systems rely on butterfly valves to control airflow. Minimizing leakage ensures energy efficiency within the building.

Food and Beverages:

Sanitary butterfly valves are used in the food and beverage industry to control the flow of raw materials and products. Low leak rates are therefore crucial to prevent contamination and maintain product quality.

Five. conclusion:

The leakage rate of butterfly valves is affected by many factors, including design, material, use environment and operating frequency. Measurement methods such as valve seat liquid testing and air tightness testing allow precise assessment of leakage rates. Understanding these factors allows us to avoid defective butterfly valve leaks as much as possible, thereby ensuring the reliability, safety and efficiency of butterfly valves in industrial, water treatment, HVAC systems and food applications.