Have you ever seen a round-shaped butterfly valve and felt curious to learn its functions? Here is a detailed guide about butterfly valve parts and function.

The invention of butterfly valves has revolutionized different industries. It has streamlined processes, such as vacuum services and compressed air operations. Butterfly valves have become effective replacements for traditional ball valves. Credit goes to their simple yet effective functioning. However, the real question is how butterfly valves work and their principles. Here is a detailed guide discussing the role of butterfly valves in various industrial operations. Scrolling through this blog will also help you to find its principles and components.

Let’s start with the basics before learning about butterfly valve parts and functions. Butterfly valves are similar to ball valves. Like the former, they regulate material flow within large pipe diameters. But the difference lies in their design and motion. Unlike a ball valve, a butterfly valve has a round disc that rotates quarterly to function. How did the valve get its name? Well, it is because of the rotational movements it conducts.

Components of the Butterfly Valve

Now comes the parts of a butterfly valve. The main structure of the valve resides in its body. It’s the body that connects to the piping systems. Here is a detailed guide about the butterfly valve parts and function:

Body

The body of the butterfly valve is the main structure connecting to the piping systems. It comes in two main designs: wafer and lug. The wafer type is placed between pipe flanges, and the lug type has threaded inserts, allowing bolt connections. The choice between the two depends on the specific application and installation requirements.

Function:

As the name suggests, the body of the butterfly valve supports all the other components. It establishes a firm connection within the valve with the piping system. The material of the body must be robust enough to withstand the pressures.

Disc

Also known as the “butterfly,” the disc is the round component that rotates to open or close the valve. You can choose from different raw materials like iron, plastic, or stainless steel. But remember that the disc’s material is crucial to its performance. Thus, choose after considering different pressures and temperature requirements.

Function:

The disc rotates to control the flow of fluid through the valve. It works on rotation at 90-degree angles. When the disc is turned perpendicular to the flow, it blocks fluid passage, closing the valve. When it is parallel, it allows fluid to pass through, opening the valve. The material and design of the disc influence the valve’s efficiency and longevity.

Seat

The seat is the sealing component located between the disc and the body. It prevents leakage when the valve is in the closed position. In general, seats are made from materials such as rubber or PTFE (polytetrafluoroethylene). The material offers resistance against damage and protects the valves from chemicals. It also ensures that its seal doesn’t lose its sealing capability.

Function:

The complete closure of the seat ensures a leak-proof seal when the valve is. It also supports the repeated opening and closing of the valve.

Stem

The stem of the valve is the shaft that connects the disc to the actuator or handle. It is usually made of stainless steel due to its strength and resistance to corrosion. It secures the connection by transmitting the rotational force ahead.

Function:

The general role of the stem is to transmit the force from the actuator to the disc, causing it to rotate. Note that a strong connection between the stem and disc is required to prevent any misalignment.

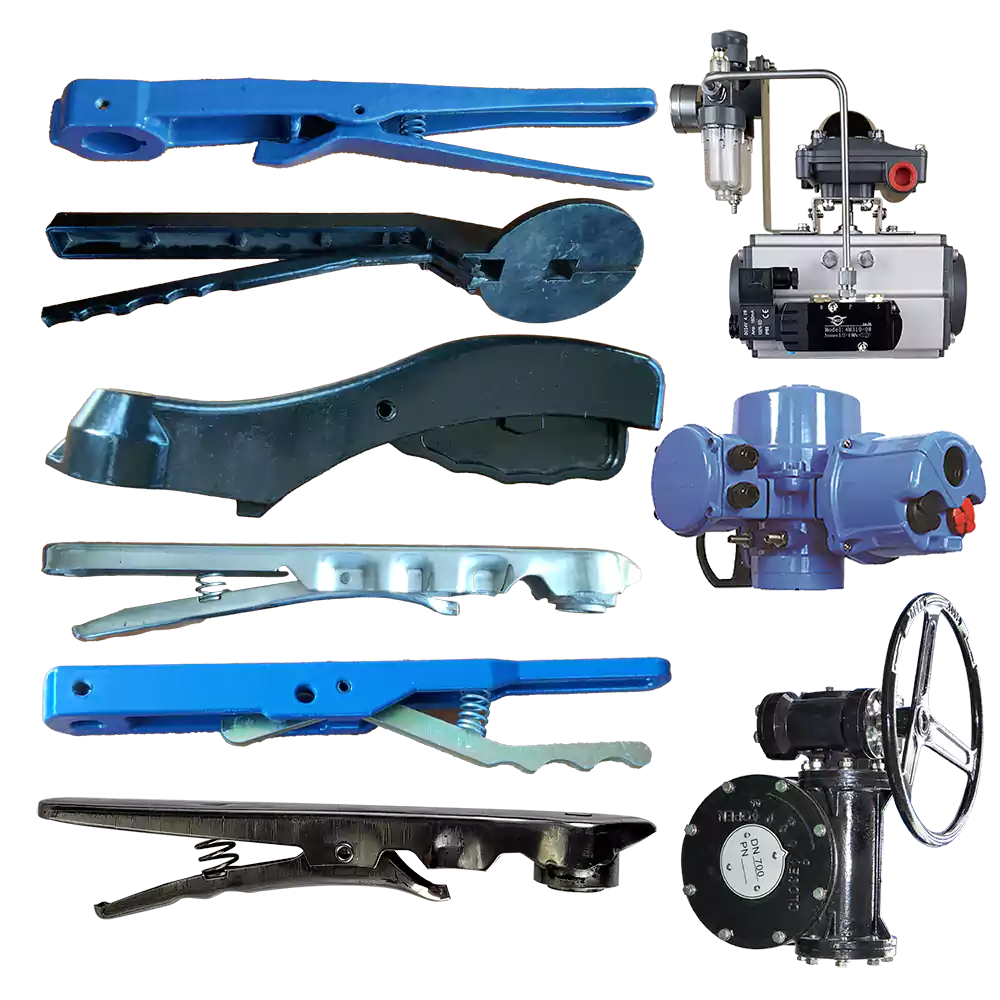

Actuator

The actuator of the butterfly valve moves the stem and disc. It can be manual, electric, pneumatic, or hydraulic. Manual actuators are simple and cost-effective. But, the electric, pneumatic, and hydraulic actuators offer more precise and automated control. You can choose one based on your speed, accuracy, and control requirements.

Function:

Manual actuators operate the valves using handles or gears. Electric actuators use motors. Pneumatic and hydraulic actuators rely on air or fluid pressure for operation. Based on the kind of operation, you can choose the one that offers you effectiveness.

Overall Working Principle of Butterfly Valve

Butterfly valves work on a simple quarter-turn operation through a disc. Different butterfly valve parts function together to achieve the results. The process occurs at 90 degrees and acts perpendicular to the flow when closed, completely blocking the fluid flow. On the other hand, when the valve again rotates to 90 degrees, it turns parallel to the flow, again allowing maximum fluid passage. The working mechanism makes the valves perfect for on-off applications. However, their use has also increased recently due to fluid regulation.

Factors to Consider While Purchasing Butterfly Valves

The first thing to consider while purchasing the valves is the quality of butterfly valve parts and functions. Other factors include:

- Need of the application

- Pressure and temperature requirements

- Size of the pipeline

- Environmental conditions

- Actuation method required

Why Are Butterfly Valves Popular?

You might be wondering why butterfly valves are popular these days. Why have they turned into frequent replacements for traditional firms? Here are the advantages of the butterfly valves:

- The foremost advantage is the compact design, suitable for tight spaces. With proper space optimization, the valves can fit anywhere you want.

- Further, butterfly valves are lightweight. Thus, they are easier to install and handle, reducing the overall expense and time. You can even opt for a DIY approach if you have basic plumbing knowledge.

- Butterfly valves’ easy and quick operation makes them ideal for everyone. Skilled and unskilled individuals, anyone can use them effectively.

- Butterfly valves work with a simple 90-degree rotation. Thus, it is perfect for a place that demands quick operations.

- Unlike traditional valves, butterfly valves are generally more cost-effective.

- Because of their fewer components and simple design, butterfly valves demand low maintenance. The parts of the butterfly valves are made using premium-quality raw materials. They can withstand weather extremes and require fewer repairs and replacements. In simple terms, the valves are effective for long-term usage.

What are the Common Applications of Butterfly Valves

You can find butterfly valves in different commercial and technical industries, including:

- Butterfly valves control the passage of fluid in water treatment plants. They can also be used in filtering systems, chemical dosing, and distribution networks. From partial to complete blockage, the valves make the entire process seamless.

- The best part is that butterfly valves can handle high pressure. Hence, these valves also manage the flow of crude oil and final products in the oil and gas industry. Industrialists use them in pipelines, refineries, and even in storage facilities.

- The butterfly valve regulates the flow of water and air in the HVAC by controlling the flow input. The desired temperature and pressure levels ensure efficient system operation.

- In power plants, butterfly valves control the flow of steam, water, and cooling fluids. Thus, their applications extend to boiler feed systems, cooling towers, and condensers.

A Way Forward

Thus, butterfly valves are versatile and efficient components in various industries. But you need to select the one that suits you thoroughly. Considering factors such as air, pressure, and temperature requirements, you can always make the right choice. Durable butterfly valve parts will best serve your process. Lastly, consider a reliable vavle manufacturer that ensures optimal performance and longevity of the butterfly valve in your system.