1. What is a butterfly valve and how does it work?

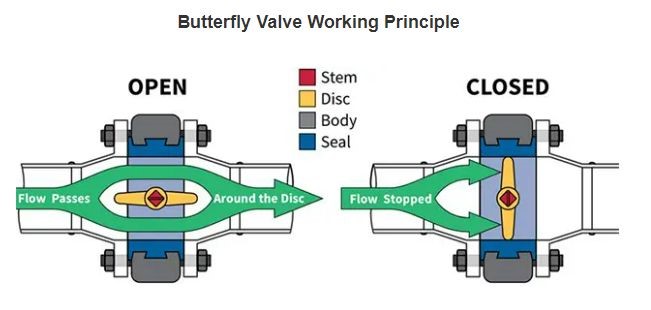

Butterfly valve, also known as flap valve, is a simple structure of the regulating valve, can be used for low-pressure pipeline media switching control of the butterfly valve refers to the closing member (valve flap or butterfly plate) for the disc, rotating around the valve axis to achieve the opening and closing of a valve. According to the above figure can be clearly seen, the butterfly valve opening and closing state.

2.What are the three types of butterfly valves?

According to the connection, butterfly valves are divided into the following categories.

Besides, there are other types of butterfly valves also be optional,

- Groove butterfly valve

- Welded butterfly valve

- Theaded butterfly valve

Zhongfa Valve can produce Wafer Butterfly Valves, Flanged Butterfly Valves and Lug Butterfly Valves.

3.What is the structure of the butterfly valve like?

Take the wafer butterfly valve and flange butterfly valve as an example, the main parts of butterfly valve are: valve body, valve plate, valve shaft, valve seat, actuator, other auxiliary parts are, sealing ring, sleeve, bolt nut, end cap, pin, upper flange and so on. According to the requirements of the actual working conditions, choose the combination of different materials, to achieve the actual use of customer demand.

Zhongfa Valve is a professional manufacturer of low pressure butterfly valve, so this article discusses low pressure butterfly valve products.

For the wafer butterfly valve products,What are the distinctive products of Zhongfa Valve?

For low-pressure wafer butterfly valve, sealing performance is a decisive factor in assessing the quality of the valve, sealing performance is inseparable from the good and bad of the seat rubber, this problem, we have discussed in the previous article, here I will not do more details. In the valve seat design, Zhongfa valve has three kinds of valve seat;

-

Vulcanized seat wafer butterfly valve

Vulcanized seat wafer butterfly valveButterfly valves with vulcanized seats, the valve body will be lighter and more affordable, commonly used in the irrigation industry where the quality of the valve is not very high and there can be leakage.

2.Replaceable soft seat wafer butterfly valve

Butterfly valve with soft seat, the valve body and valve plate can be thickened, and it can reach the pressure standard of 25kg, which is suitable for industries and markets with higher requirements for valves. And the soft seat is the easiest to replace, compared with the vulcanized seat, this butterfly valve can be used many times.

3.Replaceable hard-back seat wafer butterfly valve

The hard-backed Butterfly Valve, relative to the soft seat Butterfly Valve, the valve seat can also be replaced, but when replacing, you need to use the machine, not as convenient as the soft seat, and not as good as the soft seat Butterfly Valve in terms of pressure-bearing capacity. The thickness of the valve body is also thinner than the soft seat butterfly valve.

At present, Zhongfa Valve mainly produces soft-seat and hard-back Butterfly Butterfly Valve, and the Butterfly Butterfly Valve with vulcanized seat is gradually eliminated.

What are the ZFA types of butterfly Valves?

1. Wafer Type Butterfly Valve

let us through a picture to understand, more details, please refer to our wafer butterfly valve product information.

2. low pressure flange butterfly valve , What styles of Zhongfa valves are available?

according to the valve seat, we have the following two kinds,

-

Vulcanized valve seat FLange butterfly valve

2. Replaceable Soft Seat Flanged Butterfly Valve

Different from the wafer butterfly valve, for flange butterfly valve, the current market for the mainstream design of the valve seat or vulcanized non-replaceable seat, due to the vulcanized seat can not be replaced, making the flange butterfly valve become a one-time product, in order to solve this problem, Zhongfa Valve R & D and innovation, the development of new products that can be replaced with a new seat, through repeated experiments, successfully developed, suitable for the flange butterfly valve soft seal valve seat. So that the valve body can be reused, saving resources, but also help customers save a lot of money.

However, Zhongfa Valve’s flanged butterfly valve products with vulcanized seats are still high-quality valve products, and our butterfly valve products are able to reach 0 leakage!

3.low pressure lug butterfly valve

-

Hard-backed lug butterfly valve

For hard-seated lug butterfly valves, when used at the end of the pipeline, we will have the dead end service design, which makes the valve body and seat more tightly connected together and prevents the seat from shifting.

2. Replaceable Soft Seat Lug Butterfly Valve

Soft seat design, the seat is stuck on the top of the valve body, so that the valve body and seat are not easy to separate, when used at the end of the pipeline does not need to be fixed with a top wire, the performance is better, and, the soft seat is easier to replace, more and more customers like this design.

Zhongfa Valve is a professional low-pressure butterfly valve production factory, started producing butterfly valves in 2006, so far there have been 17 years of butterfly valve production experience, in more than ten years of production practice, Zhongfa Valve has accumulated a wealth of butterfly valve production experience, high quality to complete a variety of butterfly valves delivered by the customer’s production needs, and, at the same time, with the customer’s pioneering and innovative, and dedication of the butterfly valve cause of a piece of light and heat. Next, I will introduce some basic styles of Zhongfa Valve at present, in order to help you understand more about what kind of products Zhongfa Valve can produce.