When installing plumbing systems in your house or anywhere, you will deal with a gate valve. These valves are also standard in gas and oil pipelines, not just plumbing systems. So, before installing such a valve, one question that comes to your mind is: How does a gate valve work?

This question is crucial as it helps you deal with this valve more effectively. However, installing a gate valve without knowing it’s working and its components can be a big mistake. But you need not worry! This comprehensive article will discuss the detailed workings of gate valves. So, let’s get started!

What Is a Gate Valve?

As suggested by its name, a gate valve is a specialized device that allows or restricts fluid flow. It consists of an internal vertical barrier in the shape of a gate. When this gate is lifted, it will enable the proper flow of fluid. However, when it is lowered, it completely stops the fluid from passing.

You may have seen regulating valves. Those valves regulate the flow of the fluid by controlling its speed. But this is not the case with gate valves. These valves are designed based on switching on/off systems. Simply, gate valves either allow the fluid or completely stop it. There is no other possibility.

Gate valves are primarily used in plumbing systems near branch lines. They shut down the water supply in case of maintenance. These valves are also used in the oil refinery industries. They completely isolate the refined oil and waste. They are also used in gas pipelines, irrigation systems, and power plants.

Quick Highlight: The functionality of the gate valve is confined to just switching on and off. However, its usability is very diverse. These valves are as popular as regulatory valves, which offer more varied functionality. In fact, in some cases, gate valves are more efficient than any other type of valves.

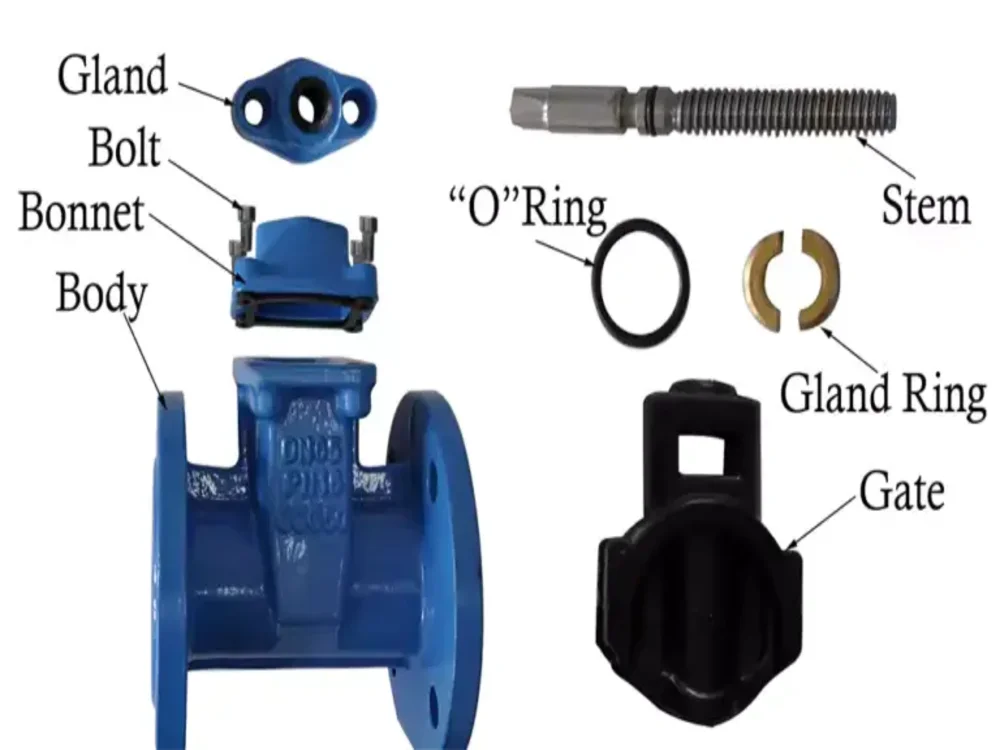

Parts of a Gate Valve

Knowing the main parts of a gate valve makes it easy to understand how it works. So, before I proceed to the main topic, let’s discuss the structure of a gate valve.

1- Valve Body

It is the external casing of the gate valve. All other components are correctly aligned in this body structure. However, the material of the valve body matters a lot. For example, it comes in iron, bronze, or stainless steel. All these materials behave differently in internal and external environments.

For instance, a stainless steel body cover best suits a plumbing system. It is excellent in terms of corrosion resistance. Moreover, it ensures that the body of a gate valve can withstand the high pressure of fluids. Furthermore, some valves are protected by external coatings. Simply put, the stainless steel material in the body provides stability to the whole gate valve.

2- Valve Gate

It is the most essential component of a gate valve. A gate is a barrier that allows or stops the fluid. The gate comes in two designs: parallel and wedge. Parallel-shaped gates are best suited for low-pressure environments. On the contrary, wedge-shaped gates can easily handle high pressure.

Generally, piping systems used at a basic level, i.e., in-home use parallel-shaped gates. On the flip side, wedge-shaped gates are suitable for more intensive use. Like a valve body, valve gates are manufactured with stainless steel or iron. These materials ensure that the gate can easily withstand temperature and pressure fluctuations.

3- Actuators

The actuator is the part that controls the closing and moving of the gate. Simply put, it controls fluid flow through a particular pipeline. Different types of actuators are available in the market. Some examples include electric, pneumatic, and hydraulic actuators.

The most popular type of actuator is controlled by human effort. Manual actuators are the most used and easiest to operate. On the flip side, automatic actuators are also popular. They automate the process of gate opening and closing. Generally, manual actuators are used in gate valves.

4- Valve Seat

The seat is the component that helps the gate work. It is the stationary platform where a gate rests while stopping the fluid. Based on valve design, a seat comes in two types: integral and replaceable. The integral seat is permanently attached to the valve body. It is cost-friendly and used for low-pressure systems.

However, a replaceable seat can be removed. It works freely and can be replaced in case of malfunctioning. Therefore, it is more expensive than the integral seat. Like other parts, the seat comes in different materials, such as metallic or non-metallic. Your requirements decide which type of material is best suited for you.

5- Valve Steam

The stem is the link between the gate and the handle wheel. It provides rotation that helps the gate move up or down. The stem comes in two designs: rising and non-rising stems. The rising stem moves linearly upward or downward with the gate. However, the non-rising stem does not move with a gate. It remains fixed while the gate moves vertically upward or downward.

6- Valve Bonnet

The bonnet is the body part that secures the internal parts. It acts as a shield that prevents the internal parts from dust. Moreover, it also enhances the sealing property of the valve and does not allow fluid leakage. However, it does not hinder the stem’s motion but enables it to move freely. There are several types of bonnets, such as blotted, screwed, and welded.

7- Handle Wheel and Packing

The handle wheel is the manual part allowing operators to run the gate valve. It can also be automated as a powered actuator. The handle wheel helps raise and lower the gate. It is designed so that rotating it clockwise closes the valve. However, rotating it anti-clockwise opens the valve.

Packing or sealing is the material that passes through the bonnet and prevents leakage. This sealing is present where the gate lowers and stops the fluid flow. It is mainly made of Teflon or graphite to withstand the high pressure of fluid.

How Does a Gate Valve Work?

As I said above, the gate valve either allows the fluid to pass or stops it. So, its working mechanism is divided into two steps. Let’s discuss that mechanism in an easy-to-understand way.

1- Opening the Gate Valve

Opening the gate valve allows the fluid to pass through the pipe. The mechanism of opening a gate valve is straightforward. But remember that in the opening state, the gate always remains lifted. When the operators move the handle wheel in an anti-clockwise direction, it stimulates the stem.

The stem pushes the gate upward or downward, allowing the fluid to pass.

The rising stem moves with the gate, while the non-rising stem remains fixed. The gate also has several grooves attached, which regulate its smooth movement. When the gate is lifted, it comes in contact with the seat. The seat keeps the gate in the same position until fluid passes.

2- Closing the Gate Valve

Closing the gate valve is the opposite mechanism. In this mechanism, the gate remains in a lowered position and stops the flow of the fluid. Let me explain this procedure: When the operator moves the handle wheel clockwise, the stem moves in the opposite direction.

This motion of the stem pushes the gate into a lower position. The gate gets fixed in the seat and stops the fluid from passing through the pipe. Here, sealing or packing plays an important role. The sealing fixes the valve in the lowered position and does not allow fluid to pass. After closing the valve, you should fix the sealing if fluid still can pass.

What Is a Gate Valve Used For?

Due to its simple closing and opening mechanism, gate valves are widely used in many projects. Let’s discuss some of their main contributions.

- A gate valve is used where a complete shutdown of fluid is required. For example, gate valves separate contaminated water from pure water in water treatment plants. These valves do not allow mixing.

- In residential plumbing systems, gate valves are installed at branching points. In maintenance, these gate valves stop the water flow and are easy to repair.

- In gas pipelines, gate valves work in isolation. They prevent gas from passing or spreading in an emergency, such as a fire.

- Gate valves also help ensure a continuous flow of fluid. In large industries, for instance, they help manage the large volume of fluid that passes through them.

- Gate valves are also used in fire extinguishers. These valves allow the regular flow of water or other fire suppresses. However, valves shut down the flow when an emergency is over.

Conclusion

Gate valves are simple valves that stop or allow fluid to pass. In this article, I have discussed their working mechanism. For example, these valves consist of a gate. When a gate valve is closed, the gate is in the lower position. When a gate valve is opened, the gate is in the lifted position.

Moreover, several components help the gate valve work efficiently. For instance, a stem provides motion to the gate valve, and a seat offers a resting platform. Lastly, gate valves are used where large-volume fluid flow is required to be managed. They are used in gas pipelines, water treatment plants, and oil refining industries.