Brief Introduction

Electric butterfly valves have revolutionized flow control in many industries and are a powerful tool for precisely managing fluid and gas systems. Combining simple traditional butterfly valves with advanced electric technology allows remote operation and smooth integration into automated control systems. Electric butterfly valves can be adjusted remotely, as electric actuators have a feedback mechanism. So, the electric butterfly valves are key in applications ranging from water treatment to industrial processes.

Electric butterfly valves work by controlling the rotation of the valve disc. This guide explores the components of electric butterfly valves and their automation applications. We will look at the advantages of electric butterfly valves, such as reduced labor costs and increased efficiency. We will also discuss their use in different industries, how to choose the right product, and options such as explosion-proof design.

1. Understand Electric Butterfly Valve Components

Electric butterfly valves have five main parts: valve body, valve disc, valve stem, valve seat, and actuator.

- The valve body is responsible for connecting to the pipeline and housing other components.

- The valve disc controls the flow of fluid. The valve stem transfers motion from the actuator to the valve disc.

- The valve seat provides a seal for the butterfly valve. The actuator in this article only refers to the electric motor, which can accurately affect the position of the butterfly disc.

Depending on the application, the valve body is usually made of ductile iron, stainless steel, carbon steel, etc., and the valve disc can also be made of different materials, such as ductile iron, stainless steel, duplex steel and aluminum bronze, etc. The valve seat is made of rubber, silicone, PTFE or metal. The valve stem is usually made of stainless steel or carbon steel and rotates no more than 90 degrees. This quarter-turn movement allows the valve disc to move between the open and closed points.

Automatic control systems make it possible to remotely operate and monitor electric butterfly valves. This reduces manual work and improves safety and productivity. Thus making modern industrial processes more efficient.

2. How Does the Motorized Butterfly Valve Function? Operation mechanism of the electric butterfly valve

How electric butterfly valves work? The electric actuator controls the valve stem, which in turn controls the rotation of the valve disc at 0/90 degrees, converting electrical energy into mechanical energy and achieving precise positioning.

When the valve disc is closed at 0 degrees, it blocks the pipeline to stop the fluid.

The valve stem rotates the valve disc 90 degrees, and the pipeline opens, allowing the fluid to pass through both sides of the valve disc.

This quarter-turn setting allows for quick closing and helps control flow. Feedback systems use sensors to detect real-time data on valve plate position, flow, and other key parameters, allowing for real-time checks and changes, thereby improving fluid control accuracy and reliability.

Feedback system:

– Position feedback: Sensors installed on the valve provide real-time data on the position of the valve plate, which can be used to monitor and control the operation of the valve.

– Flow monitoring: Flow meters and sensors are integrated with the valve to provide real-time data on the flow, allowing for precise control and adjustment.

3. Main features and advantages of electric butterfly valves

– Electric actuators enable precise valve plate positioning, which helps adjust the flow. This precision is critical for energy conservation, product quality, and production safety.

– Remote operation and monitoring through automatic control systems reduces manual labor and improves efficiency.

– One of the significant advantages of electric butterfly valves is their ability to be operated remotely. The actuator allows the operator to adjust the valve position from a distance through the control system. Especially in large industrial facilities, urgent manual operation is impractical.

– Because the butterfly valve disc is lightweight and has a small torque, it consumes less electricity, which can save energy and costs.

4. What is the actuator of a butterfly valve? Types of Electric Butterfly Valves

– Butterfly valves with switch-type actuators: These actuators are designed to fully open or fully close the valve. They are often used in applications where binary flow control is sufficient.

– Modulating actuators: Modulating actuators allow precise control of valve position, allowing the valve to be set at any position between fully open and fully closed. This feature requires a good performance butterfly valve, otherwise it will damage the valve plate.

In addition, there are some other parameters for electric actuators:

– Waterproof type: The waterproof level is usually indicated by its inlet protection (IP) rating. For example, an IP67 rating means that the actuator is dustproof and can withstand temporary immersion in water, while an IP68 rating indicates protection against continuous immersion in water. Waterproof electric heads usually use corrosion-resistant materials such as stainless steel or coated metal to extend their service life in humid environments.

– Explosion-proof type: Designed for operation in hazardous environments where flammable gases, vapors, or dusts are present, it prevents internal sparks or heat from igniting the surrounding explosive environment. The actuator housing is made of sturdy materials such as cast iron or aluminum, with thick walls to contain any internal explosions and prevent them from reaching the external environment.

5. How to choose the right electric butterfly valve

Choosing the right electric butterfly valve plays a key role in the operation, efficiency and safety of industrial systems.

When you are trying to decide which one to use, you need to consider some important things.

At this time, the electric butterfly valve needs to be divided into 2 parts, namely the electric actuator and the butterfly valve.

5.1 Factors for butterfly valve selection:

5.1.1 Properties of the fluid medium

– You must consider the temperature, pressure, and whether the medium is hard and corrosive when electric butterfly valves work. Even the type of industry you are in, the function of the butterfly valve you need, and the placement of the valve will affect your choice.

-Temperature: determines the material of the valve seat.

| NAME | APPLICATIONS | TEMP. RATING |

|---|---|---|

| EPDM | Water, potable water, seawater, alcohols, organic salts dissolutions, mineral acid solutions, mineral bases alkaline | -10℃ to 110℃ |

| NBR | Mineral and vegetable oils, gas, non-aromatic hydrocarbons, animal fats, vegetable fats, air | -10℃ to 80℃ |

| VITON | Acids, fats, hydrocarbons, vegetable and mineral oils,fuels | -15℃ to 180℃ |

| Nature Rubber | Salts, hydrochloric acid, metal coating solutions, wet chlorine. | -10℃ to 70℃ |

| Silicon Rubber | Low and high-temperature resistance, food grade Hydrocarbons, acids, bases, atmosfpheric agents | -10℃ to 160℃ |

| PU | nonaggressive chemical applications such as water, wastewater and seawater | -29℃ to 80℃ |

| HNBR | Water, Potable Water, Wastewater. | -53℃ to 130℃ |

| Hypalon | Mineral acid dissolutions, organic and inorganic acids, oxidizing substances, | -10℃ to 80℃ |

| PTFE | water, oil, steam, air, slurries, and corrosive fluids | -30℃ to 130℃ |

| SS+Graphite | High temperature and high pressure environments, such as steam systems, chemical and petroleum industries. | -200°C to 550℃ |

| SS+Stelite | all medium | -200°C to 600°C |

-Pressure: Generally, when PN≤25, soft valve seats can be used. Otherwise, metal valve seats are used.

-Corrosion: Conventional valve seats such as EPDM are somewhat corrosive. When the corrosion is relatively strong, PTFE and stainless steel valve seats can be considered.

5.1.2 External environment of butterfly valves.

The valve body material of butterfly valves is also affected by external environmental factors.

-Temperature: Ductile iron -10°C to 350°C, WCB -29°C to 425°C, stainless steel -196°C to 600°C, low-temperature steel -46°C to 345°C.

-Pressure, ductile iron can be selected for PN≤25, and carbon steel or stainless steel is recommended for higher pressure.

-Corrosion: Ductile iron is fully competent for ordinary environments. Otherwise, rubber or PTFE full lining, or stainless steel and aluminum bronze should be used.

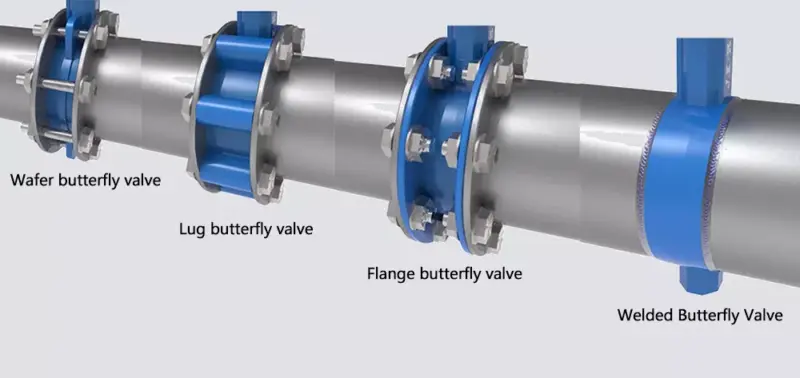

5.1.3 Connection method

a) Wafer connection butterfly valve

Advantages:

Compact structure, light weight, small installation space required.

Low cost: Compared with other connection methods, the manufacturing cost of wafer butterfly valve is lower.

Easy installation: Just clamp the valve between two flanges and fix it with bolts.

Disadvantages:

Sealing performance depends on flange tightening force: The sealing performance of wafer butterfly valve depends on the tightening degree of flange to a certain extent, and may need regular inspection and adjustment.

Cannot be disassembled and maintained separately: If the valve needs to be maintained or replaced, the upstream pipeline section must be closed.

b) Double Flange connection butterfly valves

Advantages:

Stable installation: Double flange connection provides extremely high stability, especially suitable for large pipeline systems and high pressure environments.

Reliable sealing: Double flange butterfly valve can achieve good sealing performance, and eccentric butterfly valve is especially suitable for high pressure and high temperature occasions.

Easy maintenance: The valve can be easily disassembled and replaced.

Disadvantages:

Heavy weight: Double flange butterfly valve is heavier than other connection methods and requires a more solid support structure.

High cost: Double flange butterfly valve increases manufacturing and installation costs.

c) Lug connection

Advantages:

Flexible installation: Lug butterfly valves can be installed on the end flange, allowing the downstream flange to be disassembled and the end of the pipeline to be maintained without affecting the upstream pipeline.

Compact structure, light weight, small installation space required Disadvantages (structural length is the same as the wafer butterfly valve).

Disadvantages:

Higher cost: Due to the addition of lug design, the production cost and installation cost are higher than the wafer type.

Heavy weight: Slightly heavier than the wafer type, more bolts are required for installation.

d)Single Flange connection

Advantages:

Short structural length: Single flange has a compact structure, light weight, and small installation space required.

Lighter: Compared with double flanges, single flange butterfly valves are lighter and easier to install.

Disadvantages:

Weak support: Compared with double flanges, single flange connections have poor support under high pressure.

Limited application scenarios: Mainly used in specific applications, not as widely used as other connection methods.

e)Welded connection

Advantages:

No risk of leakage: Welded connection provides the most secure and sealed connection method, completely eliminating the possibility of leakage.

Suitable for high pressure and high temperature environment: welding connection is particularly suitable for use in pipelines with high pressure, high temperature and hazardous media.

Disadvantages:

Complex installation: welding requires professional equipment and technology, installation and disassembly are inconvenient, and later maintenance is difficult.

Permanent connection: once welded, it is difficult to disassemble and replace, and the maintenance cost is high.

– Socket Welded

Advantages:

Good sealing performance: Socket connection provides excellent sealing effect, suitable for small diameter and high pressure pipelines.

No external leakage: Socket connection has no external leakage points, ensuring the safety of the system.

Disadvantages:

Professional installation: precise installation technology is required, and professional tools and personnel may be required, so it is mostly suitable for fire protection systems.

5.1.4 Correct size

You need to match it with the amount of fluid and pressure that needs to flow through. If you don’t do this, you may encounter problems such as insufficient flow or leakage.

5.2 Selection of electric head.

5.2.1 Torque requirements

The torque of a butterfly valve is usually related to the size of the valve, pressure, medium type and its operating temperature. The output torque of the electric head should be at least 1.2 to 1.5 times the maximum operating torque of the butterfly valve to ensure normal operation under extreme conditions.

5.2.2. Power supply type

Voltage: Select the appropriate voltage level according to the on-site power supply conditions, such as AC 220V, AC 380V, DC 24V, etc.

Single-phase or three-phase: Select a single-phase or three-phase electric actuator according to the power requirements. Usually a larger electric head requires a three-phase power supply.

5.2.3. Control method

Switch type: Simple on/off control, generally used in situations where only full open or full closed operation is required.

Regulating type: The opening can be accurately adjusted according to the input signal, suitable for working conditions that require precise flow control.

5.2.4 Protection level

Waterproof level: Different protection levels are selected according to different use environments. Common protection levels include IP67 (dustproof and waterproof), IP68 (waterproof), etc. If the electric head will be used outdoors or in situations where flooding is possible, IP68 is a safer choice.

Explosion-proof requirements: If the butterfly valve is installed in a flammable and explosive place (such as a flour mill), an explosion-proof electric head needs to be selected.

5.2.5 Electric butterfly valve Working environment

Temperature range: Make sure that the operating temperature range of the electric head meets the temperature requirements of the installation environment.

Corrosion: In a highly corrosive environment, a corrosion-resistant electric head needs to be selected.

6. What is the function of electric valve actuator? The role of automation in remote operation

When the electric butterfly valve is connected to an automatic control system, the butterfly valve can be opened remotely, which means no manual adjustment is required. This makes them easy to install into complex industrial processes.

The use of feedback sensors allows closed-loop control, which ensures accurate valve plate positioning. In addition, the automation system can also improve safety performance and make maintenance easier by monitoring valve performance and issuing alarms before potential problems worsen.

The automation of valve operation has a significant impact on reducing costs. It reduces the need for manual work and improves operational efficiency, allowing companies to cut overall expenses. In addition, the automation system can also reduce human errors, making industrial environments safer and more reliable.

7. What does an electric butterfly valve do? Applications and industries

Electric butterfly valves are widely used in many industries because of their versatility and ability to control fluids.

Water treatment plants use electric butterfly valves to control fluids in their systems, making operations better and more efficient.

The oil and gas industry uses them in pipeline networks, gasification plants, and LNG transportation systems to handle high-pressure flows and ensure safety.

HVAC systems rely on electric butterfly valves to manage air and water flows, which helps maintain proper temperature and humidity while using less energy.

In the food and beverage industry, electric stainless steel butterfly valves not only maintain product quality but also prevent contamination of production lines. Their ability to provide precise flow control and operate from a distance makes them indispensable in today’s industrial processes.

Conclusion

Electric butterfly valves have greatly improved flow control in various industries. They can not only be operated remotely, but also integrate seamlessly into automated control systems. Therefore, electric butterfly valves have become indispensable equipment in fields ranging from water treatment to the video beverage industry to oil and gas industrial processes. However, it should be noted that butterfly valves are not usually used in throttling situations.

The combination of electric butterfly valves with automation systems reduces the need for manual operation, enables remote monitoring, simplifies industrial processes, and enhances safety.