Many customers are butterfly valve stockists. While some remove them from pipeline and do not use them for a while. So how to store butterfly valves is also a hot topic between us. We often talk with customers and learn from each other about how to store butterfly valves. This article is from our experience.

Proper storage keeps butterfly valves working well and ensures their service life. Improper storage leads to corrosion and damage. This damage can cause failures or high maintenance costs.

The main principles for storing butterfly valves are to keep them clean, dry, and at the right temperature. If possible, keep them in their original packaging.

1. Storage preparation

1.1 Cleaning butterfly valves

Clean well before store butterfly valves. Remove all debris and liquid. Cleaning can prevent corrosion of butterfly valve components.

If it is a new valve, the maker cleans the butterfly valve after pressure testing and before shipment. This step can be omitted.

-If it has been used, this step is essential. After all, dirt, media residue, etc. may have accumulated during previous use.

1.2 Check the butterfly valve

Inspect the butterfly valve in detail to determine if there is any damage or wear. The inspection will check if the valve body, valve disc, and valve seat are corroded, scratched, or deformed.

1.3 Keep good documentation and label records

Record and save detailed information for each butterfly valve. Includes specifications, models, and conditions before storage. Besides, note the storage date as well.

These records help track inventory. They also can be used as a reference for future use of butterfly valves.

2. Ideal storage conditions

2.1 Temperature and humidity control

Butterfly valves should be stored in a place with the right temperature and humidity. This will prevent damage to parts from extreme conditions. High humidity can cause rust and corrosion. While extreme temperatures can affect the integrity of the valve seat. Soft valve seats, in particular, have higher environmental requirements.

The ideal storage environment should be 15°C to 25°C (59°F to 77°F). It should also have a relative humidity below 60%.

2.2 Protective measures

Valves are best stored in a clean, dry room. It’s the easiest and can avoid direct sunlight, rain, and high heat. Store items indoors if possible. If not, use a covered outdoor area. Ensure it has protection from wind and rain. Using a tarp or waterproof cover is also a good option.

2.3 Ventilation

Make sure the storage area is well ventilated to stop moisture. Long-term storage of butterfly valves in such a place may cause some corrosion.

3. Storage Methods

3.1 Orientation of Butterfly Valves

Store the butterfly valve in a position that minimizes the pressure on its components. The valve disc is in a partially open position to avoid deformation of the valve seat. Also, don’t stack butterfly valves directly on top of each other. Gravity may squeeze and damage the bottom layer of butterfly valve.

3.2 Pallets and Shelves

Use pallets or sturdy storage shelves to place the butterfly valves. This prevents direct contact with the floor and possible moisture. It also allows for better air circulation around the butterfly valve.

3.3 Packaging

Store the butterfly valve in its original packaging whenever possible. The manufacturer’s packaging will protect the butterfly valve even during long sea shipments.

If the original packaging is not available, use other protective materials. For example use bubble wrap to protect the valve from dust and physical damage.

4. Maintenance during storage

4.1 Regular inspections

Inspect stored butterfly valves often. Check for corrosion, dust, or damage from pests. Solve problems as they are found to prevent further deterioration. Keep a log of dates and results of lubrication, inspections, repairs, etc.

4.2 Lubrication

Butterfly valves have rotating moving parts, so it is best to lubricate them regularly. Lubrication helps prevent rust.

4.3 Rotate inventory

Implement a first-in, first-out (FIFO) system to manage butterfly valve inventory. This practice ensures that old butterfly valves are used before new butterfly valves. Proper rotation ensures optimal performance when valves are needed.

5. Handling precautions

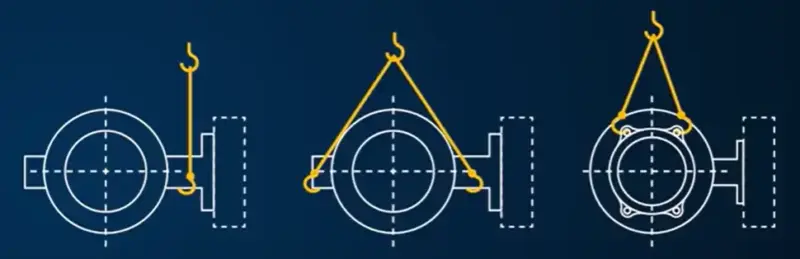

When handling butterfly valves, be careful to use proper lifting techniques. For large-diameter and heavy valves, lifting equipment such as cranes or forklifts are good choices.

Be careful when lifting butterfly valves. Avoid lifting butterfly valves by handles or actuators such as worm gears. And always consider the center of gravity to prevent tilting and rotation.

6. Training

Train all personnel involved in the storage and handling of butterfly valves. Includes training in lifting techniques, inspection procedures, and maintaining storage environmental conditions.