1. Brief Introduction

Creating a detailed document describing every aspect of butterfly valve drawings can be time-consuming, so I will divide the content into several sections. This will include the technical aspects of butterfly valves, their components, the types of drawings used, and how these drawings are used in different industries

The design and development of butterfly valves require detailed engineering drawings to ensure accuracy and functionality. Now, let’s explore butterfly valve drawings, their components, common drawing types, and their applications in different industrial settings.

2. What is a butterfly valve?

A butterfly valve is a quarter-turn valve, and the basic design includes a disc that rotates on a shaft to open or close the flow path. Butterfly valves are known for their simple structure, small size, and quick operation.

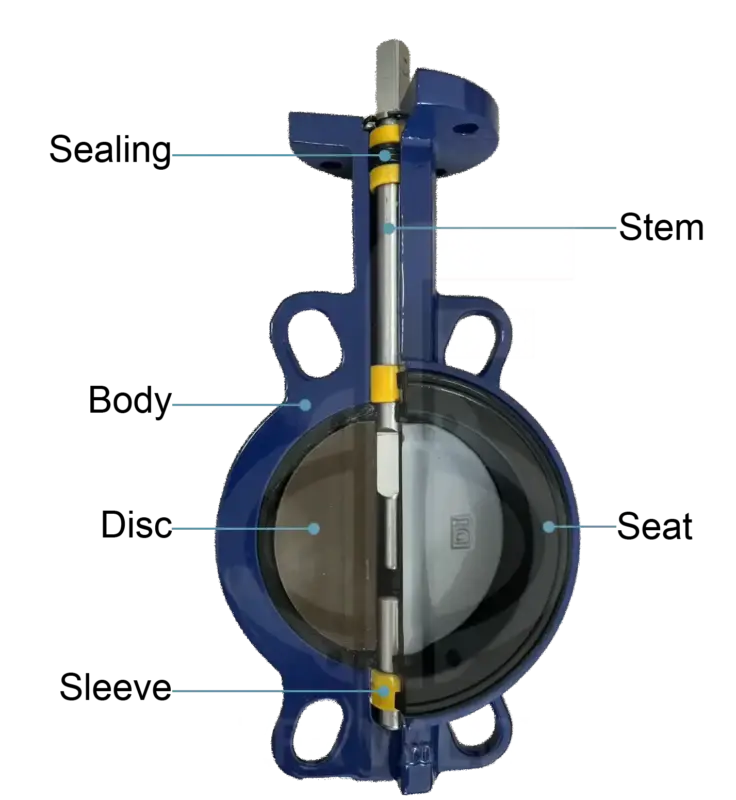

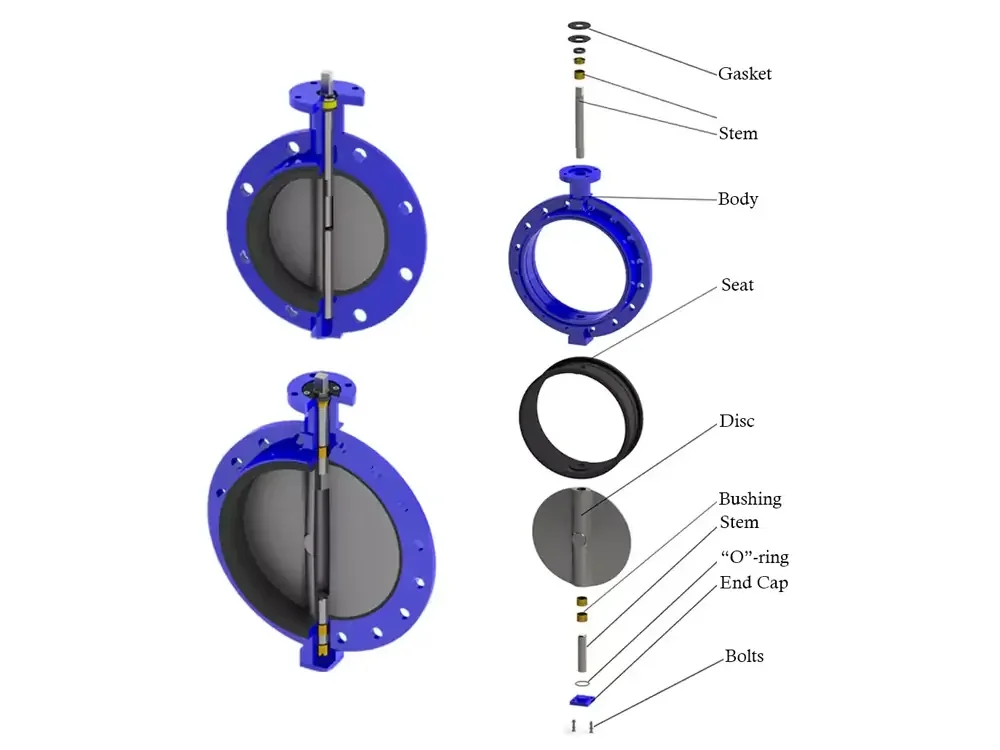

The main components of a butterfly valve include:

2.1. Valve body: The housing that houses all the internal components.

2.2. Disc: Controls the fluid by rotating in the valve body.

2.3. Shaft: Connects to the disc and controls its rotation.

2.4. Seat: Provides a seal when the valve is closed.

2.5. Actuator: Manual or electric, pneumatic, etc., used to control the movement of the shaft.

2.6. Bearings: Support the shaft and allow for smooth rotation.

Each of these components must be precisely designed to ensure proper assembly. This is where detailed engineering drawings come into play.

3. Types of Butterfly Valve Drawings

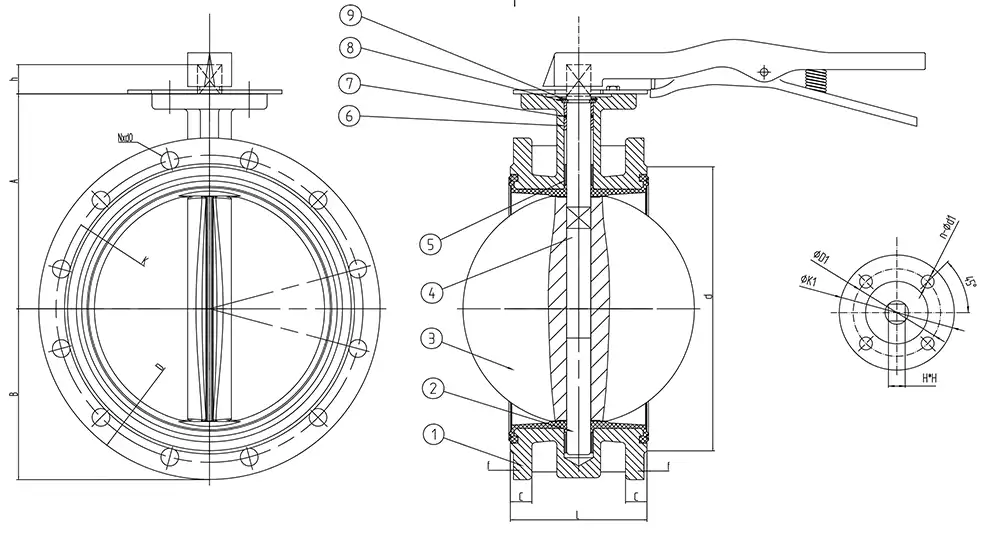

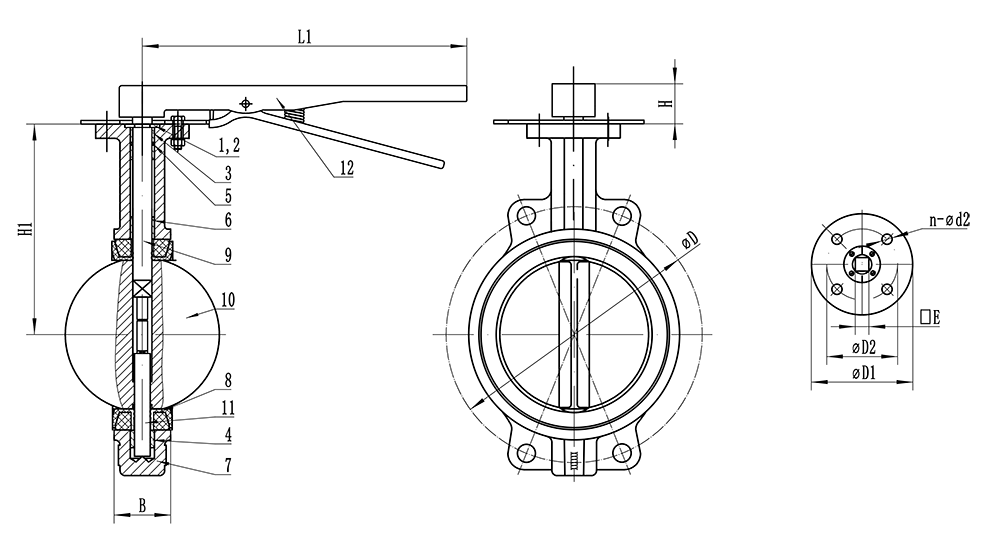

3.1. General Assembly Drawing

The General Assembly (GA) drawing is a comprehensive representation of the butterfly valve, showing all the major components and how they fit together. It provides a complete overview of the valve structure and is typically used for manufacturing and assembly purposes.

Key elements in a GA drawing:

- Sectional view: Detailed display of internal components such as the disc and seat.

- Faceted views: Front, side, top view, etc.

- Dimensions: Overall dimensions of the valve, including diameter, height, and weight.

- Material specifications: Information about the materials used for different components.

- Part numbers: Identify each component with the corresponding part number.

GA drawings are essential to understanding the overall design and ensuring that all components are aligned correctly during assembly.

Below is a partial drawing from the ZFA Butterfly valve manufacturer.

Flanged Butterfly Valve Drawing

Wafer Butterfly Valve Drawing

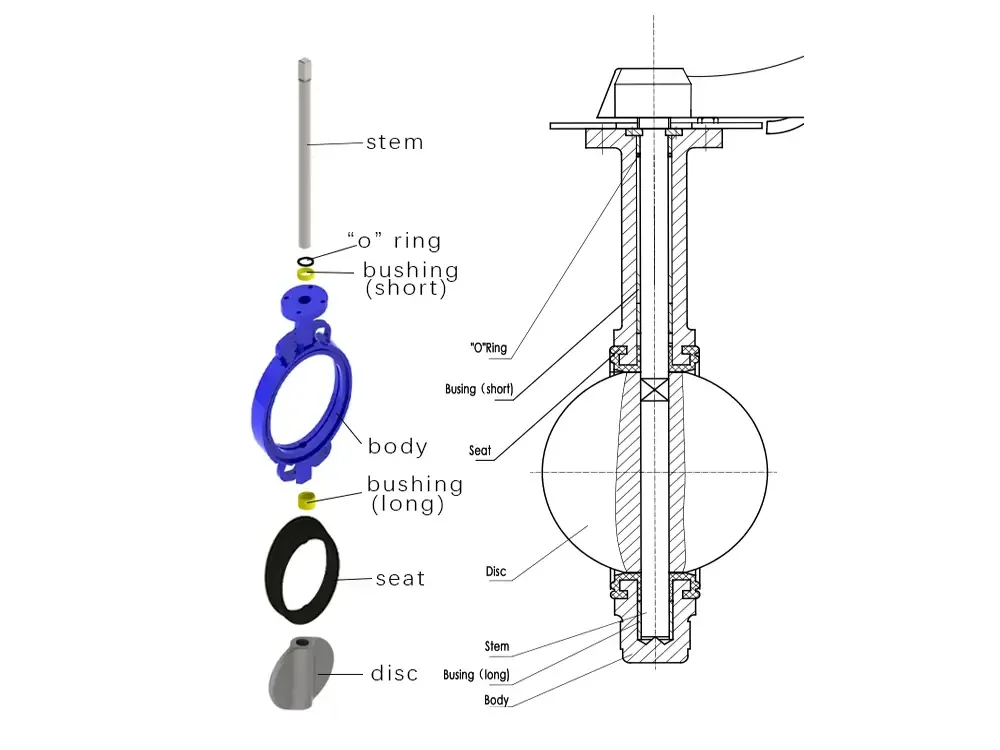

2. Exploded view

An exploded view is also a detailed illustration. It shows each component of the butterfly valve separated but in relative position. This type of drawing helps understand how the parts go together, aiding maintenance and repair operations.

Applications of exploded views:

- Maintenance guides: Help technicians understand how to disassemble and reassemble the valve.

- Training: Used as a material to train new engineers or technicians or sales and procurement personnel.

- Parts identification: Makes it easier to identify and order replacement parts.

4. Industry applications of butterfly valve drawings

4.1 Water treatment

As the name suggests, butterfly valves are used to control the flow of water in pipes. Drawings are used to ensure that the valves are designed to meet the specific requirements of these systems, such as corrosion resistance, temperature, and pressure ratings.

Key considerations for drawings:

- Material specifications: The materials used for butterfly valves in water treatment plants, such as corrosion resistant or conventional.

- Pressure rating: The design must meet the pressure rating required for safe operation.

- Compliance: The drawings must comply with industry standards, such as drinking water to follow AWWA (American Water Works Association).

4.2 Chemical processing

Butterfly valves in chemical processing plants must be able to handle corrosive chemicals and high-temperature fluids. Drawings play a vital role in ensuring that butterfly valves meet these demanding conditions.

Key considerations:

- Material compatibility: Suitable for the chemicals being processed, such as stainless steel, duplex steel, etc.

- Temperature tolerance: All components must be able to withstand high temperatures without affecting performance.

- Safety features: Safety features are included in the drawings, such as waterproof and explosion-proof actuators.

Similarly, in HVAC (heating, ventilation and air conditioning) systems, applications in the oil and gas industry, and sanitary use in the food and beverage industry, the butterfly valve drawings must provide corresponding designs.

5. Conclusion

Butterfly valve drawings are an important step in the design, manufacturing and maintenance process. Almost all customers check the drawings when confirming the price. Because they provide the details needed to ensure that the butterfly valve is manufactured to precise specifications, meets industry standards and operates properly in the intended application.

Whether it is used in water treatment, chemical processing, HVAC systems, oil and gas, or food and beverage industries, these drawings are essential tools to guide engineers, manufacturers and operators in their work.