Valves are widely used across various industries. Their importance cannot be denied, from plumbing to gas and liquid transportation. However, these valves are of different types. Among those, gate and plug valves are very popular. They have many differences providing a basis for debate on plug valve vs gate valve.

Both of these pipes offer switching on and off fluid. However, their working principles are different. Apart from working, they also differ in many other aspects. In this article, I will explain everything about these two valve types. If you are a newbie, this article will help you understand them. So, let’s get started!

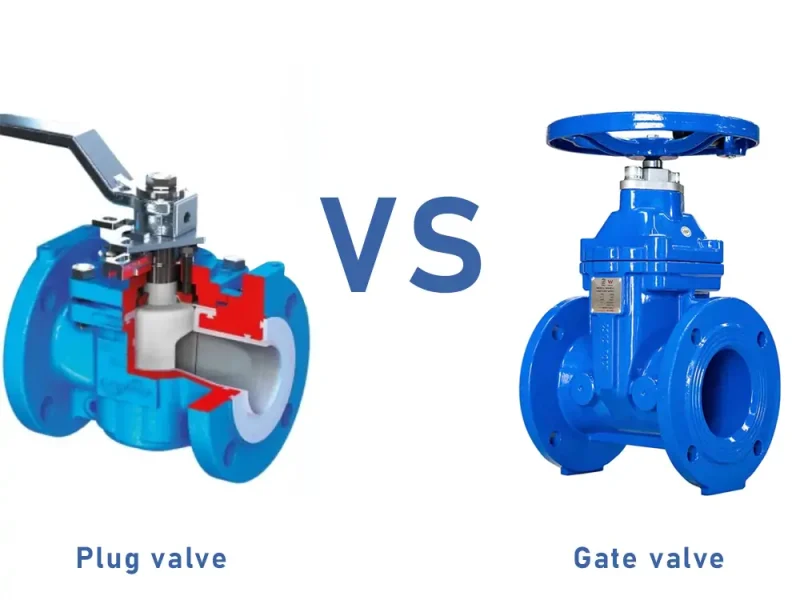

Overview of Plug Valve & Gate Valve

Both gate and plugin valves allow us to switch on or off the fluid flow. They don’t regulate the speed or direction of flow. A gate valve uses a sliding gate for on/off operations. These valves are slow and ideal for quick on/off performance. The plug valves offer faster on/off operations.

The gate valve has a wedge-shaped disc that closes the flow path. When this disc is lifted, the fluids flow. On the other hand, the plug valve works differently. It is more compact and cylindrical. It has a plug in its body. This plug has a hole that opens and stops the fluid flow.

These pipes are usable in industrial and domestic pipelines. However, their usage is generally more prominent in water and oil flow control. Interestingly, these valves are not suitable for controlling fluid flow and speed. If you half open or close them, they will likely get damaged. They work best for only fulling, allowing flow, or entirely stopping.

Working Principle of Gate Valves

We have already written a detailed guide on how gate valves work. If you are a newbie, you must read that article to understand it thoroughly. Let’s have a bird’s view of their working mechanism.

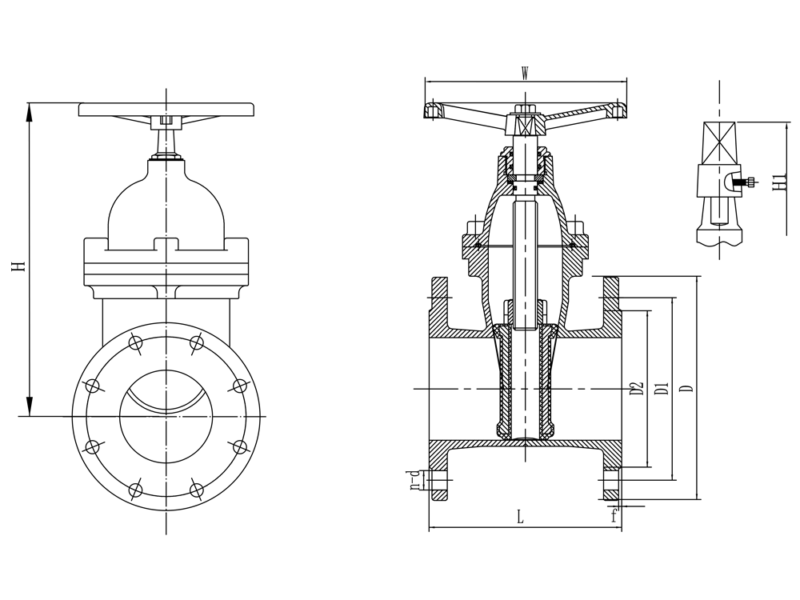

These valves have a wedge-shaped disc-like structure. This disc remains inside the valve body and moves up and down to stop or allow fluid flow. A handwheel is present at the top of the valve. When we rotate this wheel, the stem connected with the disc also rotates. As the disc is connected to the stem, rotation of the stem moves the disc.

The disc will move upward if we move the wheel in one direction. Similarly, if we move the handle in another direction, the disc will move toward it. When the disc moves upward, it allows the fluid to flow by providing a path to it. Similarly, when the disc moves toward upon moving the handle, it stops the pathway of fluid. It results in stopping fluid flow.

Working Principle of Plug Valves

The basic function of the plug valve is similar to that of the gate valve. However, its structure and work are different from those of its counterparts. The plug valve comes with a dedicated plug that is conical in shape. This plug has a tiny hole in its body. This hole is called a port and is highly important in the workings of these valves.

The plug is connected to a lever outside of the valve. When we turn this lever, the plug moves 90 degrees. In fact, the lever itself has a maximum movement of 90 degrees. Upon rotation of the lever, the plug moves, and the hole on the plug comes in line with the pipes. As a result, the fluid from the pipes enters the hole and gets to the pathway.

It results in the flow of fluid. However, the plug moves at 90 degrees when they turn the lever again. The hole of the plug doesn’t remain in line with the pipe. As a result, the plug’s solid body stops the fluid flow. This is how this plug valve works. It is easier to work with and offers faster operation due to its quick 90-degree rotation.

Gate Valve VS Plug Valve: Key Differences

Knowing how these valves work is very important. It helps in understanding their differences. The section below will discuss the fundamental differences between these gate and plug valves. So, let’s get started!

1- Valves Designs & Operation

The gate valve is generally larger and has a disc-like structure. This structure moves up and down to switch fluid flow on and off. You take the disc, which is similar to the gate. This gate moves up to allow the flow of liquid and vice versa. It remains connected with a handle. We rotate this handle to move up or down the disc depending on our needs.

Conversely, the plug valve is generally compact and easy to use. It comes with a plug with a hole in it. This external lever remains connected to this plug. We can move the lever to 90 degrees, which moves the plug. When the plug moves and the hole gets in line with the pipe, the fluid will move through the hole and flow. If we turn the level back, the hole will move away, resulting in no flow.

2- Throttling

Throttling means partially opening and closing valves, which results in small or slow fluid flow. The gate valve is very bad when it comes to throttling. Why? Because it only gives two operations: either completely off or completely on. There is no in-between for fluid flow.

If you keep the gate valve half open for throttling, it will be damaged. On the flip side, the plug valves offer decent throttling. You turn the lever to less than 90 degrees and keep the hole in front of the pipes. It won’t be entirely in line with the pipeline, so a small amount of fluid will move through the hole.

The fluid flow speed will be small, and you will get throttled. Remember, the plug valves are also sensitive to throttling. You can only do it when you have no other options. I don’t recommend doing this regularly as it can damage the valve. However, between the gate valve and plug valve, the latter is superior as it offers small throttling if done carefully.

3- Opening Time

The plug valve offers excellent “opening time” and works very fast. The reason is that the levers of these valves require a turn of only 90 degrees. This quarter turn (90 degrees) ensures that the plug’s opening quickly comes in line with the pipes. So, the fluid flows through the valves. It offers quick shut-off and is suitable for emergencies.

On the flip side, the gate valve is very slow to open and close. Why? Because it comes with a wheel handle. You’ll have to rotate the wheel handle multiple times to move the disc completely up or down. So, these valves are not ideal for quick shut-off. Remember, the bigger gate valves are even slower in switch-on/off operations.

4- Flow Control Capabilities

Both valves are excellent in terms of flow control capabilities. Once switched off, they won’t allow any small quantity of fluid to pass through. Moreover, even if they handle high-pressure fluid, they don’t offer leakage issues. The plug valve provides some additional features to control the speed of flow.

You can turn the plug valve to the half position, reducing the speed efficiently. However, the gate valve will only offer on/off operation. When switched off, it won’t allow any fluid to pass through. Trying to half-open the gate valve might cause vibration, erosion, and leakage issues. Therefore, I highly recommend avoiding half-opening or closing gate valves.

5- Material and Durability

The plug valve is generally made from cast iron. However, you’ll also see valves of stainless steel, brass, and other materials. They vary in terms of their performance and usability. Their internal plug is highly lubricated and lined with PTFE. This makes the plugin very durable, even against slurries. Therefore, these valves can be used for harsh chemical transportation.

On the other hand, the gate valves also consist of cast iron, stainless steel, or bronze. However, their internal disc is generally not lined with PTFE. Due to this, the disc can undergo rusting over time. Therefore, these gate valves are typically used in water supply lines. Their usage is not recommended for lines transporting slurries or harsh chemicals.

6- Resistance to Pressure & Temperature

The gate valve offers better performance in high-pressure and temperature conditions. This is mainly due to its smooth working mechanism. The disc moves up and down slowly, so in extreme conditions, this slow movement of parts proves helpful.

Imagine if the temperature is too high. The parts of the valve move very fast, which results in faster wear of parts. In the plug valves, the plug moves very fast. Under high temperatures or pressure, the wear and tear of this plug is more common. Therefore, I consider the gate valve a superior option in high-pressure and temperature conditions.

7- Cost & Usability

The gate valves are cheap compared to plug valves. However, they offer slow operations and are not efficient. On the other hand, plug valves have a high initial cost. However, they are speedy and provide decent throttle as well. Moreover, their usage is common in quick shut-off situations.

Both of these valves are used in different applications. However, plug valves are more durable and long-lasting. They have internal parts lined up with PTFE. So, they are used in transporting harsh chemicals and slurries. The gate valves are suitable for water transportation. Here is the table showing their applications:

| Plug Valve Applications | Gate Valve Applications |

| Chemical transportation | Water systems (for long-term flow control) |

| Water systems (for clean or dirty flow) | Steam systems (for high-pressure applications) |

| Slurry or thick fluid systems | Oil and gas (high-pressure pipelines) |

| Compact space applications | Large pipelines (requiring full open/close) |

| Oil & gas pipelines (for corrosive fluids) | Wastewater treatment (where flow is not adjusted) |

Which One Should You Choose, Plug Valve VS Gate Valve?

There is no one fit for all regarding plugging vs. gate valve selection.

You should choose plug valves if you want excellent performance. With efficient fluid controls, you will get better durability. Its Compact size and quick opening (off/on) are also great benefits. Moreover, it can also work best if you want to transport harsh chemicals or slurries.

However, the cost of plug valves is relatively high, which is a big drawback. I won’t recommend choosing this valve if you have a tight budget. Instead, you should prefer gate valves. Although they have some limitations, they are very affordable. Before choosing any of these, I highly recommend analyzing your needs.

Frequently Asked Questions

What is the difference between a gate valve and a plug valve?

The primary difference between these valves is their working. The gate valve has discs that move up and down for on/off operations. The plug valve has a plugin with a hole in it. The plug moves 90 degrees to allow the fluid to pass.

Is a plug valve the same as a gate valve?

No, the plug valve is entirely different in shape and workings. It is faster, offers decent throttle, and has excellent durability. Moreover, the plug valve’s opening and closing time is very fast. Due to these features, the plug valve is a superior option.

What is the purpose of a plug valve?

The purpose of plug valves is to operate on/off in the fluid flow. They offer quick working, resulting in more fluid flow control. The role of the gate valve is also the same, but it is slower and inefficient compared to plug valves.

Conclusion

Both gate and plug valves are excellent devices. They help to switch on and off operations in fluid flow. Their usage is common across many industries. However, many seem to be double-minded when it comes to their selection. As I said earlier, these valves serve the same purpose but have different workings and features.

Those features can create confusion. I have discussed all the key differences between plug and gate valves in this article. In my opinion, plug valves are a superior option over gate valves. However, your final decision should be based on your needs and usage requirements.