The price of butterfly valves varies due to a variety of factors. Understanding the key factors affecting butterfly valve prices not only helps with purchasing decisions, but also optimizes project budgets.

This article will delve into the 8 main factors that affect butterfly valve prices, combining industry trends and actual cases to provide practical insights.

1. The direct impact of material selection on price

The material is one of the core factors that determine butterfly valve prices. The price difference of each material is significant, and it directly affects the corrosion resistance, high temperature resistance and service life of the butterfly valve. Choosing the right material is not only about cost, but also closely related to project safety and long-term maintenance costs. When purchasing, the most cost-effective material should be selected according to the characteristics of the medium and the working conditions.

At this point, you need to first understand the structural composition of the butterfly valve before you can analyze and select the material of each component.

As shown in the figure: The butterfly valve is mainly composed of a valve body, a valve plate, a valve shaft, and a valve seat.

1.1 Selection of valve body material

Common butterfly valve body materials include cast iron, ductile iron, stainless steel, carbon steel, alloy steel and special materials.

1.1.1 Ordinary materials:

Ductile iron butterfly valves are usually used in low-pressure, low-corrosive water treatment systems. They are relatively cheap and suitable for projects with limited budgets. Usually the valve body needs to be treated with anti-corrosion, such as epoxy resin for acid and alkali resistance, suitable for water, oil, and weakly corrosive media; or tungsten carbide coating for wear and corrosion resistance, suitable for strong acid and strong alkali environments.

1.1.2 High-performance materials:

Stainless steel (such as 304 or 316) duplex steel (such as 2205 or 2507) or alloy steel butterfly valves are suitable for highly corrosive environments such as chemical and marine environments, and their prices are much higher than cast iron valves. For example, the durability of 316 stainless steel butterfly valves in acidic media makes it the first choice in the chemical industry.

1.2 Selection of valve plate material

Common butterfly valve disc materials include cast iron, ductile iron, stainless steel, carbon steel, alloy steel and special materials.

1.2.1 Ductile iron, WCB and LCB/LCC, etc.:

* Epoxy resin coating: acid and alkali resistant, suitable for water, oil, weak corrosive media, coating thickness 100-300μm.

* PEFE/PFA: thickness 1-3m, wear-resistant, high temperature resistant, corrosion-resistant, suitable for chemical, pharmaceutical and food processing.

* Electroplating: electroplating corrosion-resistant metals such as nickel, chromium or zinc on the surface of the valve plate, thickness 10-50μm.

* Nylon coating: thermoplastic polyamide coating, through electrostatic spraying, dipping or fluidized bed coating process, thickness 200-1000μm. It has excellent corrosion resistance and wear resistance.

1.2.2 High-performance materials

Usually, stainless steel, duplex steel, aluminum bronze and other alloy steels have excellent corrosion resistance, so they can be used directly.

1.3 Selection of valve stem material

Austenitic stainless steel 304, 316, with a tensile strength of about 520MPa, is suitable for medium pressure conditions.

Martensitic stainless steel 420 (2Cr13) 431, with a tensile strength of 700-1000MPa after heat treatment and high hardness (HRC 40-50).

Duplex stainless steel 1.4462, with a tensile strength of about 650-850MPa, is resistant to high pressure.

Stainless steel 7-4PH: with a tensile strength of 1000-1300MPa after heat treatment and a hardness of HRC 38-44.

Monel: Monel 400 has a tensile strength of about 550MPa, and K500 can reach 1000MPa after strengthening.

1.4 Selection of valve seat material

| NAME | APPLICATIONS | TEMP. RATING |

| EPDM | Water, potable water, seawater, alcohols, organic salts dissolutions, mineral acid solutions, mineral bases alkaline | -10℃ to 110℃ |

| NBR | Mineral and vegetable oils, gas, non-aromatic hydrocarbons, animal fats, vegetable fats, air | -10℃ to 80℃ |

| VITON | Acids, fats, hydrocarbons, vegetable and mineral oils,fuels | -15℃ to 180℃ |

| Nature Rubber | Salts, hydrochloric acid, metal coating solutions, wet chlorine. | -10℃ to 70℃ |

| Silicon Rubber | Low and high-temperature resistance, food grade Hydrocarbons, acids, bases, atmosfpheric agents | -10℃ to 160℃ |

| PU | nonaggressive chemical applications such as water, wastewater and seawater | -29℃ to 80℃ |

| HNBR | Water, Potable Water, Wastewater. | -53℃ to 130℃ |

| Hypalon | Mineral acid dissolutions, organic and inorganic acids, oxidizing substances, | -10℃ to 80℃ |

| PTFE | water, oil, steam, air, slurries, and corrosive fluids | -30℃ to 130℃ |

| SS+Graphite | High temperature and high pressure environments, such as steam systems, chemical and petroleum industries. | -200°C to 550℃ |

| SS+Stelite | all medium | -200°C to 600°C |

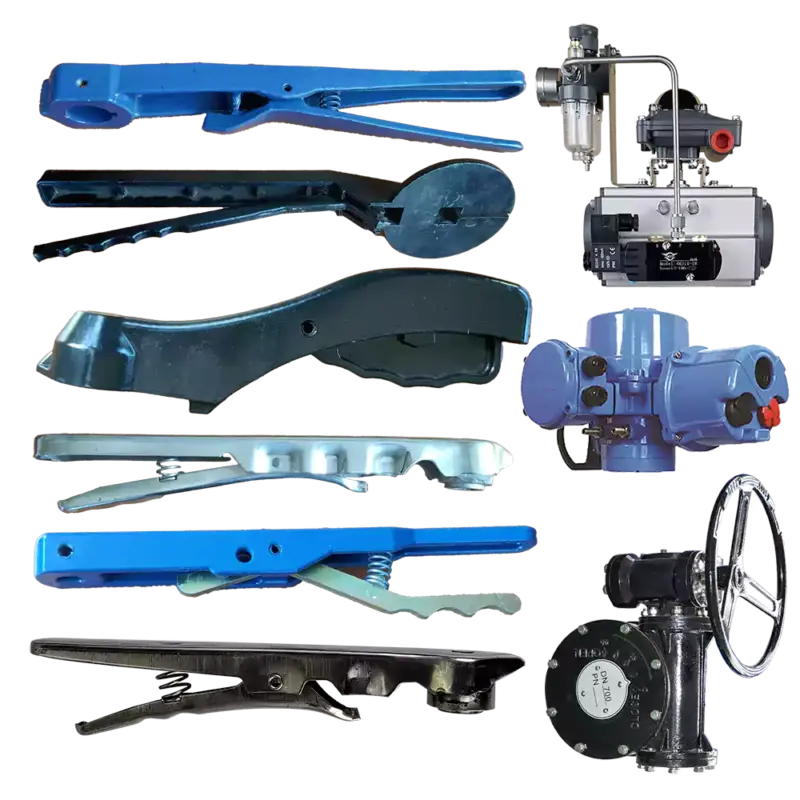

1.5 Selection of drive actuator

Common drive modes include manual, electric, pneumatic and hydraulic, and the cost difference of each mode is obvious.

1.5.1 Manual butterfly valve:

Operated by handle or worm gear. The handle has a simple structure and the lowest price, which is suitable for small DN≤250 or low-frequency operation scenarios. The worm gear is suitable for butterfly valves of various calibers, and it strikes a balance between torque, automation and price.

1.5.2 Electric butterfly valve:

Equipped with electric actuator, it can realize remote control and is suitable for automated production lines. The brand, performance of electric actuator such as waterproof level, explosion-proof level and control accuracy directly affect the price.

1.5.3 Pneumatic butterfly valve:

In scenarios where fast switching is required, pneumatic butterfly valves are favored because of their fast response speed. However, the complexity of pneumatic actuators and the requirements of supporting air source systems further increase the price.

Industry trend: With the growth of automation demand, the market demand for electric and pneumatic butterfly valves continues to rise.

2. Structural design and process complexity of butterfly valves

The structural design of butterfly valves directly affects the manufacturing cost and final price.

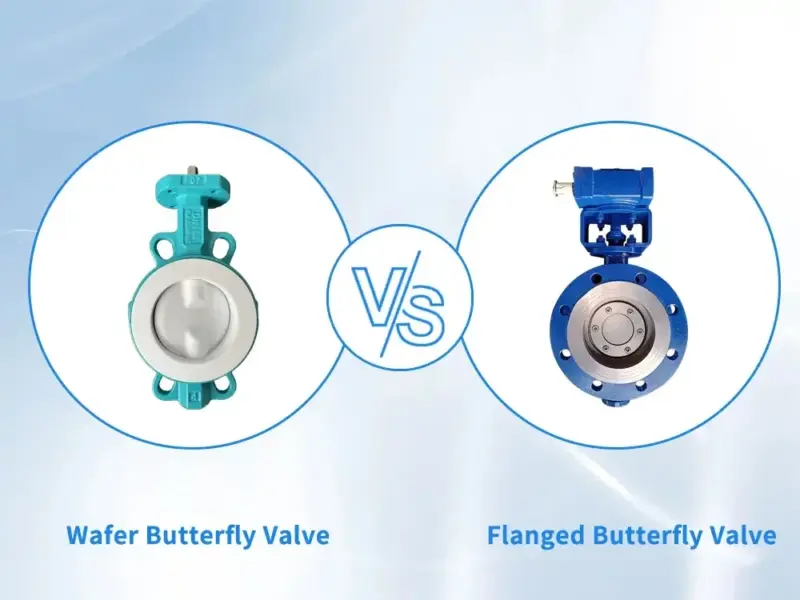

Common butterfly valve types include wafer-type, lug-type and flange-type butterfly valves according to the connection method; they can be divided into centerline, double eccentric and triple eccentric butterfly valves according to the valve plate structure.

The process complexity and application scenarios of each type are different.

2.1 Connection method:

* Wafer-type butterfly valve: simple structure, easy installation, suitable for low-pressure systems, and low price.

* Lug-type butterfly valve: There are threads in the ears along the valve body. Although the structural length is the same as that of the wafer butterfly valve, the valve body is heavier than the wafer butterfly valve, so the price is slightly higher than that of the wafer butterfly valve.

* Flange butterfly valve: There are two circles of flanges on both sides of the valve body, which are more firmly connected and are applicable to low, medium and high pressure systems. Of course, because more materials are used and the weight is greater, this type of butterfly valve is the most expensive for the same valve plate structure.

2.2 Valve plate structure:

* Central butterfly valve: The structure is the simplest, and the valve seat is a soft-sealed butterfly valve. Suitable for low-pressure systems.

* Double eccentric butterfly valve: Compared with the centerline butterfly valve, the double eccentric butterfly valve is more resistant to high pressure. Suitable for medium and low pressure systems. The price is moderate, higher than the centerline butterfly valve and lower than the triple eccentric butterfly valve.

*Triple eccentric butterfly valve: It adopts a multi-layer or all-metal sealing design, suitable for high temperature and high pressure environments, with complex manufacturing processes and relatively high prices.

In addition, some special working conditions require customized butterfly valves, such as valve discs with special coatings or valve bodies of non-standard sizes, which will significantly increase costs. Customized designs may involve additional mold development and testing costs, and the price may double. The sophistication of the production process, such as the polishing accuracy of the valve disc and the processing technology of the sealing surface, will also push up costs. High-precision processed butterfly valves perform better in sealing and durability, but the price is correspondingly higher.

3. Differences in specifications and sizes

The specifications and sizes of butterfly valves directly affect the material usage and processing difficulty, thereby affecting the butterfly valve prices. Generally, the larger the nominal diameter (DN) of the butterfly valve, the higher the price.

*Small butterfly valve (DN50-DN300): Suitable for small pipeline systems, with low material and processing costs.

*Medium and large butterfly valves (DN300-DN1200): As the size increases, the material cost of the valve body, valve disc and seals increases significantly.

*Super large butterfly valve (DN1200 and above): Commonly used in large water treatment or power projects, it is difficult to manufacture, and the transportation and installation costs also increase accordingly.

In addition, non-standard butterfly valves require customized molds and special processing, which further increases the cost. When purchasing, it is necessary to weigh the cost-effectiveness of standard sizes and customized sizes.

4. Standard differences

The impact of differences in butterfly valve standards on butterfly valve prices is mainly reflected in design requirements, material selection, manufacturing process, testing and certification, and applicable working conditions. Different standards (American standard API/ANSI, European standard EN, Japanese standard JIS, etc.) have different requirements for the structure, performance, materials and testing of butterfly valves, which directly affect production costs and market pricing.

*Structural design: such as the type of valve disc eccentricity (centerline, single eccentricity, double eccentricity, triple eccentricity), the sealing design of the valve stem and valve seat.

*Structural length: The standards of different countries also have different provisions for structural length.

*Material requirements: material standards for valve body, valve disc, valve stem, and seals.

*Test requirements: pressure test, leakage test, corrosion resistance test, etc.

*Certification requirements: such as API, CE, ISO 9001, etc., increase certification costs.

5. Differences in pressure levels

Different pressure levels (such as national standard PN10/16/25, Class 150/300/600, or JIS 10K/20K) have different performance requirements for the valve body, valve disc, valve stem and seals of butterfly valves, which directly affects production costs and market pricing.

*China standard (GB/T 12238): PN6, PN10, PN16, PN25, PN40 (unit: MPa, 1MPa≈10bar).

*American standard (API 609/ANSI B16.34): Class 150 (PN20), Class 300 (PN50), Class 600 (PN100).

*European standard (EN 593): PN10, PN16, PN25, PN40.

*Japanese standard (JIS B2032): 10K, 20K (1K≈0.1MPa).

The increase in pressure level (from PN10 to Class 600) has pushed up the price of butterfly valves through higher-end materials, more complex structural design (thick wall, metal seal), more stringent testing (zero leakage) and certification requirements.

6. Brand and market positioning

Brand effect plays an important role in the price of butterfly valves. Internationally renowned brands such as Emerson, Flowserve or domestic first-line brand Sufa, their products are more expensive due to quality assurance and after-sales service.

* International brands: Take Emerson’s Keystone series butterfly valve as an example. Its high reliability makes it an advantage in the high-end market, but the price may be much higher than ordinary brands.

* Domestic brands: Domestic manufacturers such as Sufa have advantages in cost performance, product quality is gradually approaching international standards, and prices are more competitive.

* Small and medium-sized manufacturers: Some small and medium-sized manufacturers provide low-priced butterfly valves, but they may lack in material consistency or quality inspection, and long-term use may increase maintenance costs.

ZFA suggestion: When choosing a brand, it is recommended to consider product quality, after-sales service and price comprehensively, and avoid blindly pursuing low prices while ignoring long-term operating costs.

7. Market supply and demand and external economic factors

The price of butterfly valves is also affected by market supply and demand and external economic factors. These factors are often dynamic and need to be closely monitored.

*Raw material price fluctuations: The prices of raw materials such as stainless steel and alloy steel are greatly affected by the global market. For example, the surge in nickel prices in 2022 caused the price of stainless steel butterfly valves to rise by 20% in the short term. Pay attention to the dynamics of the raw material market when purchasing.

*Production and logistics costs: Rising energy prices or increased transportation costs (such as a surge in sea freight costs) will push up the ex-factory price of butterfly valves.

*Regional market differences: Tariffs, labor costs and market demand in different regions will also affect prices. For example, butterfly valves in the Southeast Asian market may be cheaper than those in the European and American markets because of their lower labor and production costs.

8. Certification and industry standard requirements

Industry certification and standard compliance of butterfly valves will also affect prices. Different industries have different performance requirements for butterfly valves, which must meet specific certification standards such as API, ISO, CE, WRAS or SIL.

* API certification: API 609 standard butterfly valves commonly used in the petrochemical industry require rigorous testing and have higher production costs.

* ISO 9001: Quality management system certification to ensure standardized production processes and consistent product quality.

* CE certification: EU market access certification that meets health, safety and environmental requirements based on standards such as EN 593 (butterfly valves).

* WRAS certification: Water Regulations Advisory Scheme, a British drinking water safety certification, ensures that valve materials do not pollute water quality. Requires valve parts that come into contact with drinking water (such as valve plates and seals) to pass non-toxic and odorless tests.

* SIL certification: In safety instrumented systems, butterfly valves must meet SIL (safety integrity level) requirements, involving additional design and testing costs.

* Food grade certification: In the food or pharmaceutical industry, butterfly valves must comply with FDA or EHEDG standards, usually using high-purity stainless steel and special surface treatment, and the price is significantly higher than ordinary industrial butterfly valves.

Purchasing advice: When selecting a butterfly valve, it is necessary to clarify the certification standards required for the project to avoid unnecessary costs due to excessive pursuit of high standards.

9. Summary and purchasing advice

The price of butterfly valves is affected by multiple factors such as materials, design, drive mode, specifications, pressure, brand, market supply and demand, and certification requirements. When purchasing, it is recommended to start from the following aspects:

*Clarify the working conditions: Select appropriate materials and structures according to the medium, pressure and temperature to avoid over-design.

*Balance brand and cost-effectiveness: Consider brand reputation and product quality comprehensively and choose a supplier that fits your budget.

*Focus on long-term costs: Low-priced butterfly valves may increase costs in maintenance and replacement, and a comprehensive assessment of life cycle costs is required.