valve manufacturer: how to choose the right material of butterfly valve

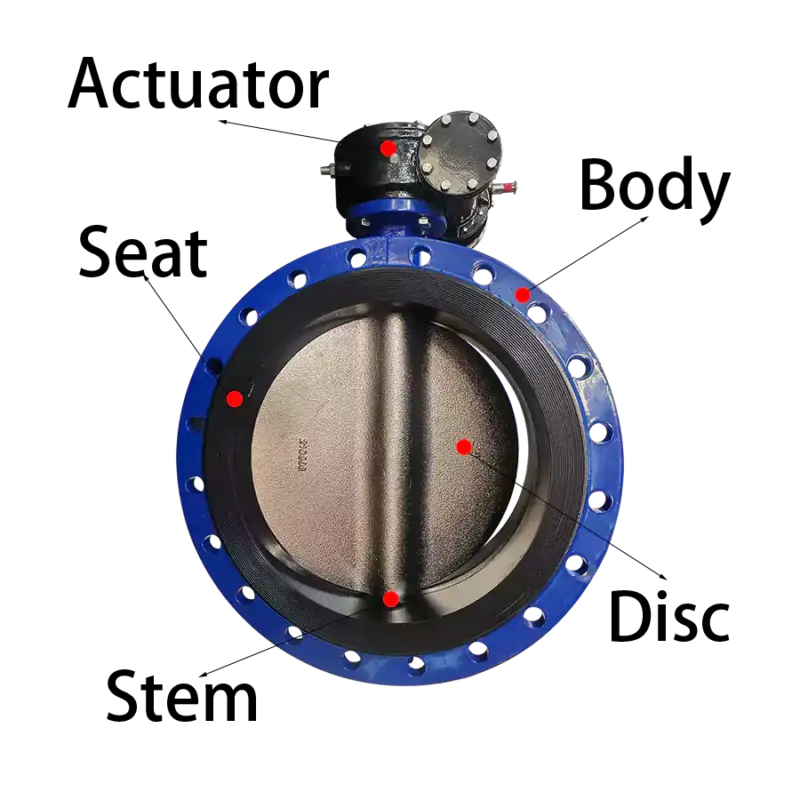

Before choosing the material, first of all, the parts of butterfly valve have to be displayed.

- Body: The main part of a butterfly valve, it is a housing of all other components.

- Disc: The flow-controlling part that rotates to open or close the valve.

- Seat: The sealing surface inside the body, against which the disc seals to stop flow without leakage.

- Stem: The spindle connected to the actuator or handle to turn the disc.

- Actuator: The mechanism that operates the valve, including handle, worm gear, electric, pneumatic, or hydraulic type.

Choosing the material of the butterfly valve body and seat for butterfly valves based on different media involves considering the properties of the media, including temperature, pressure, corrosiveness, and operating environment. Here are some guidelines for material selection based on different media characteristics:

1. Temperature and Pressure:

For high-temperature and high-pressure media, materials that can withstand these conditions, such as high-temperature alloys or stainless steel, are suitable. Low-temperature applications may require materials with good low-temperature toughness.

2. Corrosiveness:

If the media is corrosive, selecting materials that are corrosion-resistant, such as stainless steel or corrosion-resistant alloys, is important. Different types of corrosion, such as acid corrosion or alkali corrosion, may require different materials.

3. Media Type:

Depending on whether the media is a liquid, gas, or solid, as well as its characteristics (viscosity, solid content, etc.), different materials may be required to ensure smooth fluid control.

4. Operating Environment:

Considering whether the butterfly valve will be used indoors or outdoors, as well as the environmental factors it may be exposed to (e.g., moisture, corrosive gases), durability and weather resistance of the materials should be considered.

Here are some common material options for butterfly valve body and seat, categorized based on different media characteristics:

General Applications:

– Stainless steel (e.g., 304, 316)

– Carbon steel

– Cast iron

Corrosion-Resistant Media:

– Nickel alloys (e.g., Hastelloy)

– Titanium alloys

– Corrosion-resistant alloys (e.g., Monel)

High-Temperature Applications:

– High-temperature alloys (e.g., Inconel, Incoloy)

Low-Temperature Applications:

– Low-temperature carbon steel

Chemically Corrosive Media:

– Polytetrafluoroethylene (PTFE, Teflon)

– Polypropylene (PP)

– Polyethylene (PE)

It’s important to note that each material has its specific advantages and limitations. Therefore, when selecting the material for the valve body and seat of butterfly valves, it’s crucial to consider the media’s properties, operating conditions, material availability, and cost. In specific applications, consulting with professional engineers or valve manufacturers is recommended to obtain more accurate advice.