Introduction:

In this article, you will discover the key components of a butterfly valve, its mode of operation, the various types available, as well as diverse ways this device is applied. By the end of this article, you will have the answer to “What is a butterfly valve” and also have enough knowledge to determine if a butterfly valve is the most suitable option for your operation.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn device that offers both on-off and regulatory services within piping systems. It is lightweight, portable, cost-effective, and comes in varying orifice sizes. The name of this valve originates from the design of its disc or plate, which resembles a butterfly. This “butterfly” is a circular disc that rotates on a central axis and moves either parallel to allow flow or perpendicular to impede the flow.

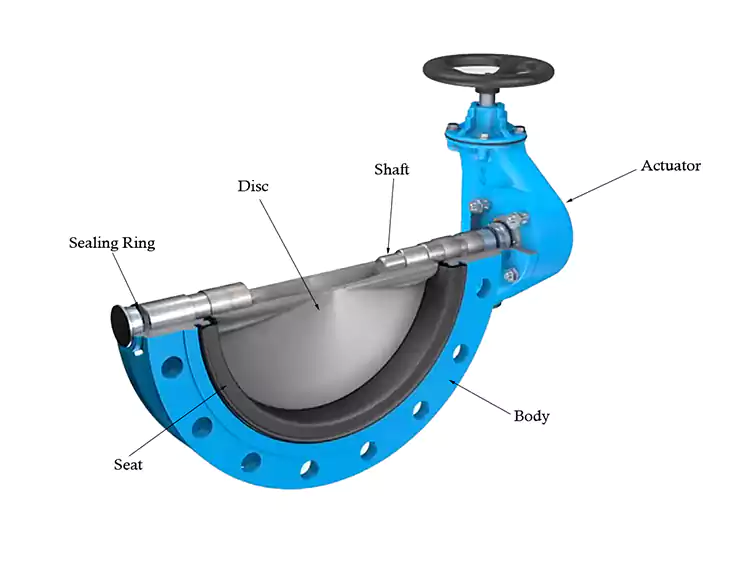

Key Parts of a Butterfly Valve

A butterfly valve has three main components; namely the body, disc or plate, and the stem and actuator.

1. Body:

The body of a butterfly valve is the main component that houses the internal parts and attaches to the pipeline.

2. Disc or plate:

This component is located centrally within the body and rotates to control the flow of fluid media. When the disc turns in a parallel direction, there will be a smooth passage of media, and when it turns perpendicularly, fluid flow is blocked.

3. Stem and actuator:

A stem acts as the bridge between the disc and the actuator. It attaches the disc to the actuator and ensures that the disc is in the correct position for flow control. An actuator mediates the rotation of the disc either manually – lever or gear, or automatically- pneumatic, hydraulic, or electric.

How Does a Butterfly Valve Work?

Butterfly valves are known for their simplicity, ease of use, and versatility in many industries, which makes them suitable for operations where quick control of flow is crucial.

They have three main positions in their operational mechanism. In the open position, the actuator turns the valve parallel to the flow direction to allow the flow of fluid media. In the closed position, the actuator rotates the disc perpendicularly to block the flow entirely. The midline between these two positions is the intermediate position which regulates or throttles flow through the partial turning of the disc.

The disc maintains a position in the flow path and allows a linear or equal movement of fluid depending on the rotation of the handle. When the rotation is incomplete, the handler can adjust the flow to be either throttled or proportional.

The quarter-turn feature of butterfly valves allows for swift and efficient control of the media flow. When the valve disc is halfway opened or closed, it results in an even or moderate flow of media. There are two ways to operate a butterfly valve: manually and automatically.

The manual method of operation involves the use of a gear or hand lever. A hand lever is ideal for smaller butterfly valves. It is this lever that allows the valve to be in three positions: fully open, partially open, and completely closed. Gears, on the other hand, are mainly for large butterfly valves that use a gearbox to increase flow while reducing the opening/closing speed.

Butterfly valves operate automatically by utilizing electricity to rotate the stem. Additionally, they rely on compressed air or hydraulic pressure to manoeuvre a piston or diaphragm, facilitating the opening or closing of the valve.

Butterfly Valve Types

A butterfly valve comes in many designs, each of which caters to specific performance requirements in different operations.

1. Wafer Butterfly Valves

A wafer butterfly valve is known for its slim design, which allows the device to fit between two pipeline flanges without the need for additional bolts. This butterfly valve is economical in design and versatile in its application. The sandwiched design of a wafer valve allows the device to regulate the flow of fluid media, and prevent backflow in universal flow systems.

2. Double Eccentric Butterfly Valves

Unlike a concentric valve, a double eccentric butterfly valve is slightly off-centre from the centreline of the pipe. Its stem does not pass through the disc centreline but goes around it in the opposite direction of flow.

This offset layout helps in the reduction of wear and friction on the seal when opening or closing the valve.

Double eccentric butterfly valves are essential in systems that require a long service life, such as systems that handle viscous or abrasive fluids. They are also suitable for leak-proof performance in chemical processing, water treatment, and oil and gas industries.

3. Triple Offset Butterfly Valves

True to its name, a triple offset butterfly valve is a unique valve type that features three offsets, namely; the shaft, seat, and centreline of the seat. These three components create a cone-shaped seat surface that provides an all-metal sealing contact between the seat and the disc. The unique design of a triple offset butterfly offers excellent sealing capability and ensures a tight shut-off under high temperatures and pressures.

The application of this type of butterfly valve is most observed in places where high temperatures and pressures are in constant use, such as the oil and gas industries, as well as the petrochemical and refining industries.

4. Flange Butterfly Valve

Flange-style butterfly valves are easy to install and have the same basic design as other butterfly valve types. However, the distinguishing feature of these valves is the fusing of flanges directly onto the body of the valve, which removes the need for separate flanges within the pipeline. Applications of this valve are common in HVAC systems and water treatment plants.

5. Lug Butterfly Valve

The design of a lug butterfly valve features threaded inserts or lugs on its outer circumference. These lugs serve as attachment points for bolts during the installation process, while the valve itself is fastened between two flanges.

Lug-style butterfly valves are useful in applications that require frequent maintenance, such as in petrochemical industries.

6. High-Performance Butterfly Valves (HPBV)

These are advanced types of butterfly valves which function in demanding conditions that normal valves cannot manage. They are sturdy and more expensive due to the strength of the materials used in their making.

HPBVs feature a robust construction that is capable of handling extreme temperatures and pressures. Their designs are typically double or triple-offset, and hence, offer tighter sealing along with lesser friction during operation.

Applications of Butterfly Valves

If you have ever wondered, “What is a butterfly valve used for”, your answers await you in this section. Butterfly valves play a crucial role in many industries and applications, such as, in agriculture and irrigation by efficiently distributing water across agricultural fields, and simultaneously aiding in water conservation. They also aid in the disposal of waste and produce in chemical plants, sewer systems, food processing plants and the oil industry. Another additional application of these valves is in pharmaceutical manufacturing, where the precise movement of medicinal substances is crucial.

Butterfly Valves VS Gate Valves

Some people find it difficult to decide between a butterfly valve and a gate valve for a specific application. These two types of industrial valves are both used to control the flow of fluids within pipelines and piping systems. However, each type serves distinct purposes that make them suitable for certain kinds of operations.

For example, a gate valve is ideal for operations that require a free and forceful flow of fluid. In contrast, butterfly valves offer the handler more control when adjusting the flow of the fluid media, and can be shut much quicker than gate valves.

Gate and butterfly valves serve similar purposes. They both function to regulate media flow, either by permitting or obstructing its pathway. While these two devices share some similarities, it is important for you to also understand the differences before choosing the best valve for your application.

1. Mode of operation

Generally, a butterfly valve closes faster than its gate valve counterpart because of its design, which grants quick disc rotation. However, the rapid closure of a butterfly valve creates a phenomenon called “water hammer”- which is the surge of pressure in a piping system after a sudden stoppage or redirection. This abrupt stoppage or redirection of media generates high pressure that can cause damage to the valves, pipes, and other systems.

2. Regulation of flow

A butterfly valve regulates flow by throttling or modulating the fluid passing through when the position of the disc is adjusted. This characteristic allows for varying degrees of flow control within the valve. In contrast, gate valves operate primarily in an on/off manner. This means that gate valves can either allow full flow when the valve is completely open, or full stoppage when the valve closes completely.

3. Weight

Due to its design and construction, a butterfly valve weighs less than gate valves as they are often lighter and more portable. Gate valves tend to be heavier, especially at larger sizes, due to their solid gate mechanism that increases the overall weight. This makes gate valves more labour-intensive during handling.

4. Cost

A butterfly valve is typically less expensive than a gate valve. This is a result of several factors which contribute to the lower cost expense of butterfly valves. Among these factors is the simpler design in comparison to gate valves, which results in lower production costs.

It is also easier to install and maintain a butterfly valve because it has fewer moving parts and a simple design. However, although they are generally cheaper, it is best to consider not only the initial costs when deciding between a gate valve and a butterfly valve but also factors like performance, durability, and suitability for specific applications.

5. Flow resistance

The term flow resistance refers to the obstruction or resistance a fluid encounters as it passes through a valve or piping system. Using this definition in the context of gate and butterfly valves, flow resistance plays a vital role in understanding how both types of valves operate.

Gate valves offer less flow resistance than butterfly valves due to their design. When the gate is fully open, the fluid passes smoothly through the valve without obstruction. As a result, there is low pressure drop across the gate valve, unlike in a butterfly valve with similar flow conditions. This trait is advantageous in systems that require high flow rates with the least loss of energy.