Butterfly valves are very popular due to their ease of use. Their effective performance to stop the flow makes them stand out. However, the use of flanged butterfly valves is also increasing. Their usability is more common in heavy-duty piping systems. However, many still don’t have any idea about these valves. So they ask: What is a flanged butterfly valve?

Remember, flanged butterfly valves are a subtype of butterfly valves. Their overall working mechanism is similar to that of the butterfly valve. However, their installation in the piping system is what makes them different. I’ll explain everything about flanged butterfly valves and their usability in this article. So, let’s get started!

Overview of Flanged Butterfly Valve

The flanged butterfly valve is a type of butterfly valve with an additional flange. Both sides of these valves have a flange with a bolt hollow on it. These flanges attach to the pipes and remain intact with the bolt put in those holes. They stop, allow, and regulate the flow of fluid.

These valves also have discs, just like simple butterfly valves. This disc rotates and allows or stops the flow of the fluid. The flanged butterfly valves differ from other types due to their connection points. These valves come with flanges. This word might confuse you.

The flange is a flat rim with a bolt hole in a circle form. You can bolt on these holes and attach the valve to the pipes. In the past, valve attachment was a real issue. The attachment point showed a leakage issue when high-pressure fluid flowed through it. However, this modern flange does not show any leakage issues.

This flange makes these valves used in heavy-duty applications like oil and gas transportation. Both sides of these valves have flanges. As I said earlier, flanges are flat rims with bolt holes on the sides. Both sides of these valves have flanges, which connect with pipes. You can then tighten the bolt to ensure that no leakage-related issue happens.

Quick Highlight: The flanged butterfly valves have easily removable joints. You can remove the bolt and valve from the pipes. It means that these valves can be used in different piping systems. You can use it on one pipeline. Once you use it there, remove the bolt, remove the valve, and use it in another pipeline.

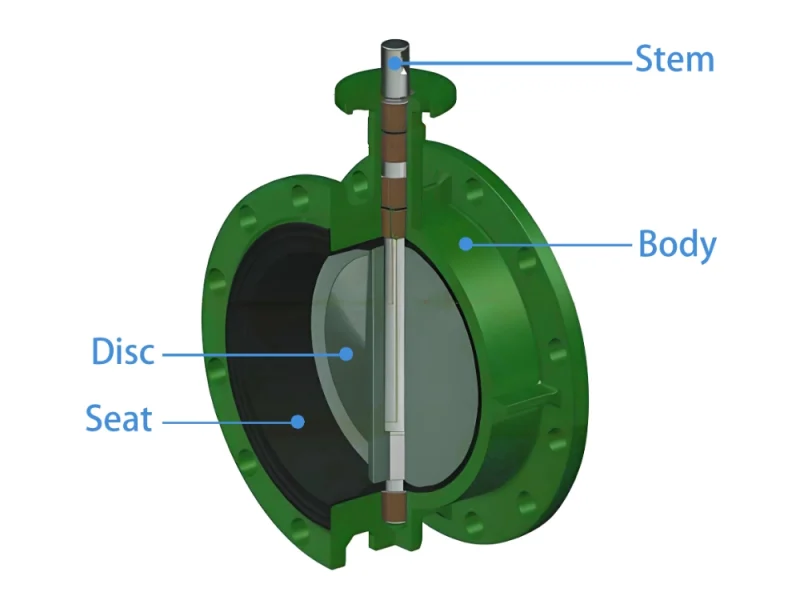

Components of a Flanged Butterfly Valve

The working of flanged butterfly valves depends on several components. The role of each of these components is crucial. Remember, flanged and simple butterfly valve parts are similar. Let’s discuss these components:

- Valve Body: The valve body is the exterior covering of the box containing the valves. It also includes the flanges at both ends of these valves. All other parts and components of these valves remain inside the body.

- Butterfly Disc: This is a key part of the workings of flanged butterfly valves. It rotates either parallel to the flow or perpendicular (against the flow). When it is parallel, it allows fluid flow and vice versa. Different types of butterfly discs are available.

- Stem (Shaft): The disc mentioned above connects with the handle through this stem. So, when you turn the handle, the stem transmits the torque to the disc. As a result, the disc rotates to allow or stop the fluid flow.

- Seat (Sealing): Simply put, the seat in these valves is like a sealing. The disc presses against this seat to stop the fluid flow. Once the disc presses, the fluid flow stops. Once this is done, sealing does not allow any small fluid leakage.

- Actuator or Handle: The outer part controls the fluid flows. It can be either manual, electric, or even hydraulic. You simply rotate this handle to move the disc present inside. It indirectly stops and allows the fluid flow.

How Does a Flanged Butterfly Valve Work?

I understand the flange butterfly valves are not very common. Due to this, people don’t have a detailed understanding of how these valves work. So, I will explain how they work simply. So, let’s get started!

1- Attachment of Valve

As I said earlier, these valves have flanges on both ends. Remember, the flange consists of bolt holes in the corners. Right? All you will have to do is put bold on these holes and tighten them. First, keep the valve in the location where you want to install it. You should put both flanges in line with the pipes. Then, add the bolt in the flange holes and install these valves. Moreover, you should tighten the bolt to avoid leakage issues.

2- Opening/Allowing of the Fluid Flow

Let’s discuss how these valves work to allow the flow of fluid. In the closed position, the disc remains perpendicular to the flow. In this way, the disc stops the passage through which fluid flows. Now, you turn the actuator at a 90-degree angle.

Once you do it, the disc will rotate at 90-degree angles. The disc will be positioned parallel to the fluid flow. It allows the fluid to pass through. Remember, the actuator is attached to the disc through the stem. Once you move the actuator, the stem takes the torque and transmits it to the disc. As a result, the disc moves, allowing the flow of fluid.

3- Closing/Stopping of the Fluid Flow

It is time to close or stop the fluid flow. Once the disc is parallel or in line with the flow, it results in fluid flow. Now, you turn the actuator degree back. This will result in the disc going back to the perpendicular position. The disc will come against the passage through which fluid flows. This way, the fluid flow stops, and the seat (sealing) further airtightens the passage.

4- Partial Open (Throttling)

Sometimes, we need fluid throttling, which means partial fluid flow with pressure. Interestingly, the flange valves allow us to do throttling. For this, you turn the actuator to half stage. For example, don’t turn it at 90 degrees; instead, turn it at a 30 or 40-degree angle.

This will result in a slight rotation of the disc. This way, the disc will move partially, allowing small fluid to pass. You can adjust the extent of the flow by moving the actuator. Is it recommended to throttle? The answer is a big NO! Partially opening or closing the valve can result in its wear and tear.

Manual VS Automated Flange Butterfly Valve

Both manual and automated flange butterfly valves are available. Their primary functionality is to regulate (stop or allow) the fluid. However, they operate slightly differently.

The manual flange butterfly valve has a manual handle or actuator. This actuator is moved or turned with human hands. Once you turn the flange by hand, it will work the same as discussed above. These manual flange butterfly valves are inexpensive and easy to use. Moreover, their regular maintenance is also affordable.

On the other hand, the automated flange butterfly valves are more costly and premium. They don’t have a handle that can be turned by a human hand. Instead, their actuator can be either electric or pneumatic. You can switch the valve on or off without touching the actuator. These valves work by instruction from a switch or dedicated control panel.

The fluid will pass or stop once you put on these butterfly valves. There is no need for humans to turn the handle. Some modern flange butterfly valves can also be controlled by software. Remember, these valves are costly and used in heavy-duty and high-end piping systems. I recommend you choose a manual valve for routine usage.

Advantages of Flanged Butterfly Valve

As I said earlier, flanged butterfly valves have quickly become very popular. Their popularity is due to the benefits and features they offer. Let’s explore the key benefits of flanged butterfly valves.

- Fast Operation: First, the flange butterfly valves are easy to work with. You can use the handle to control the fluid’s flow. Turn the actuator at a 90-degree angle to stop or allow the flow. That’s how easy it is to use these valves!

- Easy Installation: As I said earlier, these valves have flanges on both sides. These flanges have bolt holes, which allow quick installation. You can put the bolt in the hole of the flanges to install them securely.

- Versatile in Usage: These valves are very versatile. They allow you to switch off/on or even throttle the fluid. Moreover, these valves are suitable for bearing high-pressure fluid. They can also be used in gas transportation pipelines.

- Secure Connection: These valves offer a secure connection below the valve and piping. The bolt present in the hole firmly tightens the connections. This results in no leakage issues. The connection point remains in good shape even when the high-pressure fluid flows.

- Space-Saving Design: One of the key advantages of these valves is that they are compact. Their weight is also not too high. This ensures that you can easily install these valves. They won’t occupy more space when you install them.

- Affordable & Cost-Effective: Flange valves are relatively less expensive and require low maintenance. Moreover, parts of these valves are also available at cheap prices. This makes their repairs easy and cost-effective. You won’t have to worry if they go out of order.

Frequently Asked Questions

Can I use flange butterfly valves for both liquids and gases?

Yes, flange butterfly valves are very versatile. They can control or regulate the flow of liquid and gas, and they can handle liquids with very high pressure.

How do I control the flow with a flange butterfly valve?

These valves have handles. You turn the handle, and the disc attached to the handle through the stem rotates. It comes in line with the flow, offering passage for fluid to flow. Once you rotate back, the disc blocks the passage of fluid.

What benefits do I get from using flange butterfly valves?

Flanged butterfly valves offer many benefits, including compact size, perfect sealing, no leakage, and excellent versatility. Above all, they are very affordable, which makes them stand out.

Conclusion

Flange butterfly valves are a type of butterfly valve with a flange on the ends. These flanges allow users to connect or install the valve quickly and easily. Moreover, their compact size and lightweight make these valves stand out.

So, the next question is: Should you choose these valves? The answer is YES. It is no mistake that these valves offer value for money. They can perform excellently in very high-pressure conditions. When used in heavy-duty applications, they won’t show any sign of leakage or wear and tear. However, they may not be suitable for small-scale use.