Valves are an integral part of many industries, from drinking water and wastewater treatment to oil and gas, chemical processing, and more. They control the flow of liquids, gases, and slurries within the system, with butterfly valves and ball valves being particularly common. This article explores the reasons why we choose butterfly valves over ball valves, delving into their principles, components, design, operation, and advantages.

Butterfly Valve Over Ball Valve: Principle and components

a. Butterfly valve

A butterfly valve is a quarter-turn rotary motion valve used to stop, regulate, and start fluid flow. The movement of the butterfly valve disc mimics the movement of a butterfly wing. When the valve is fully closed, the disc completely blocks the passage. When the disc is fully open, the disc rotates a quarter turn, allowing fluid to pass through almost unrestricted.

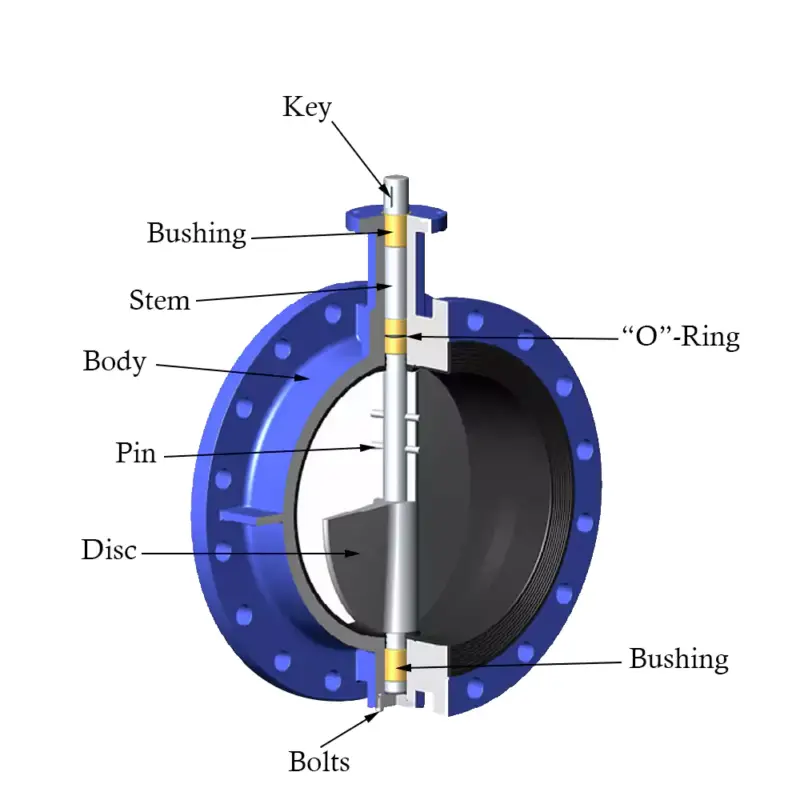

Components of butterfly valve:

-body: usually annular, the main component of a butterfly valve.

-disc: located in the center of the valve, the opening and closing part of the butterfly valve, controlling whether the fluid flows or not.

-stem: connects the actuator and the disc.

-seat: provides a seal between the disc and the valve body.

b. Ball valve

A ball valve is also a quarter-turn valve, but its opening and closing part is a spherical ball. The ball has a hole in the middle, and when the hole is aligned with the flow path, the valve opens. When the hole is perpendicular to the flow path, the valve closes.

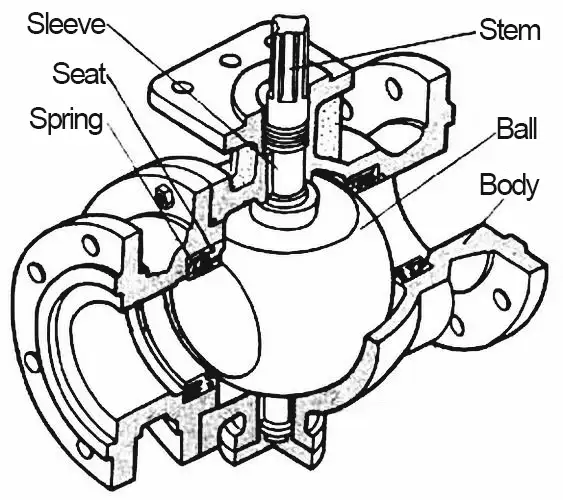

Components of ball valve:

-Body: Made up of one, two, or three parts.

-Ball: Located in the valve body, rotates to open or close the valve.

-Stem: Connects the ball to the actuator.

-Seat: Provides a seal for the ball.

Butterfly Valve Over Ball Valve: Differences in Design

The fundamental difference between butterfly valves and ball valves is their design and operating mechanism. These differences affect their performance characteristics and suitability for various applications.

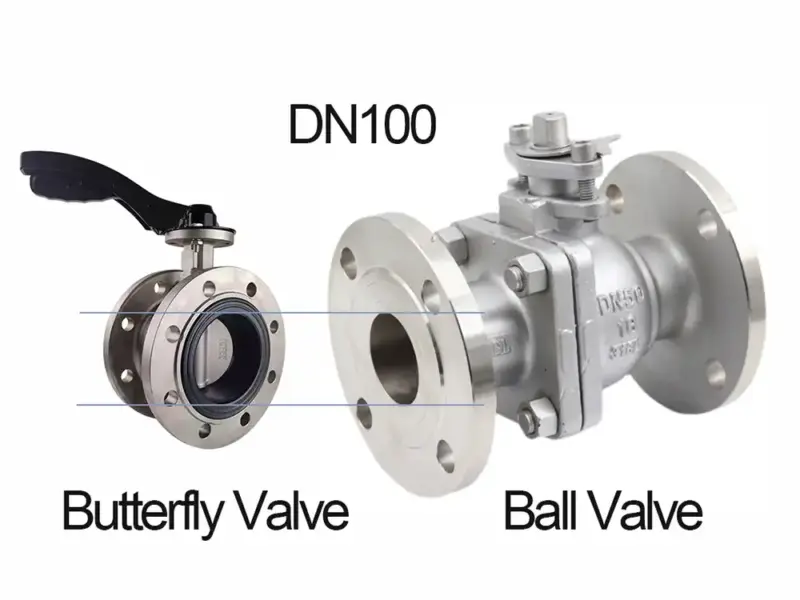

Dimensions and Weight

Butterfly valves are generally lighter and more compact than ball valves, especially in larger sizes. The short structure design of butterfly valves makes them easier to install and maintain, especially in applications with limited space.

Weight comparison of flanged ball valve and flanged butterfly valve of DN100 (without actuator)

| Ball valve | Butterfly valve |

| 25kg | 10.5kg |

Cost

Because butterfly valves have a simpler design and fewer parts, they are generally cheaper than ball valves. This cost advantage is more obvious in larger valve sizes. The lower cost of butterfly valves makes them ideal for large-scale applications of valves.

Pressure drop

Butterfly valves typically have a higher pressure drop than ball valves when fully open. This is due to the position of the disc in the flow path. Ball valves are designed with full bores to provide lower pressure drops, but many suppliers will reduce the bores to save costs, which will cause a large pressure drop in the medium and waste energy.

Advantages of butterfly valves

Versatility of application

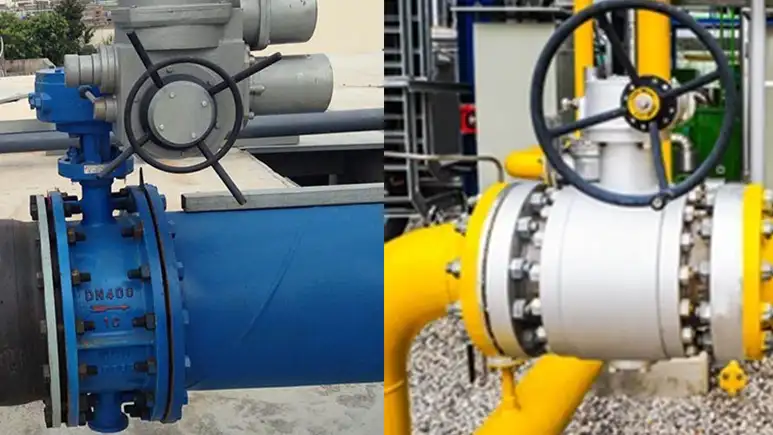

Butterfly valves are widely used and can handle a variety of fluids, such as water, air, steam, and certain chemicals. They are used in a variety of industries, including water and wastewater treatment, HVAC, food and beverage, chemical processing, etc.

Compact and lightweight design

The compact and lightweight design of butterfly valves makes them ideal for applications with limited space. Due to their light weight, less structural support is required for installation, thereby reducing installation costs.

Cost

Butterfly valves are generally more cost-effective than ball valves, especially in large sizes. They are cheaper to manufacture and cheaper to install, which, combined with lower maintenance requirements, can save a lot of money over the life of the valve.

Lower torque requirements

The torque required to operate a butterfly valve is lower than that of a ball valve. This means that smaller and cheaper actuators can be used, reducing overall system costs.

Easier to maintain

Butterfly valves are simple in design and have fewer parts, making them easier to maintain and repair. It is usually not necessary to remove the valve from the pipeline to replace the valve seat, etc. (so our company recommends replacing soft-seat butterfly valves for those that need to be replaced frequently), thereby minimizing downtime.

Precautions and limitations

Although butterfly valves have many advantages, certain precautions and limitations should be noted:

Diameter

The smallest diameter that ZFA valve can achieve is DN25, and it is generally believed that the minimum diameter of butterfly valves is larger than the minimum diameter of balls, DN15.

Sealing performance

Although butterfly valves can provide adequate sealing for many applications, they may not achieve the same level of leakproofness as ball valves, especially in critical applications involving hazardous or toxic media.

Media characteristics

Compared with butterfly valves, ball valves are more suitable for slurries with impurities. The ball of ball valves is sharper, so the sealing performance is better for such media.

Conclusion

Butterfly valves offer significant advantages in cost, size, weight, and ease of maintenance, making them ideal for a wide range of applications, especially in water and wastewater treatment, HVAC systems, and the food and beverage industry. That why we choose butterfly valve over ball valve. However, for small diameters and slurries, ball valves may be a better choice.