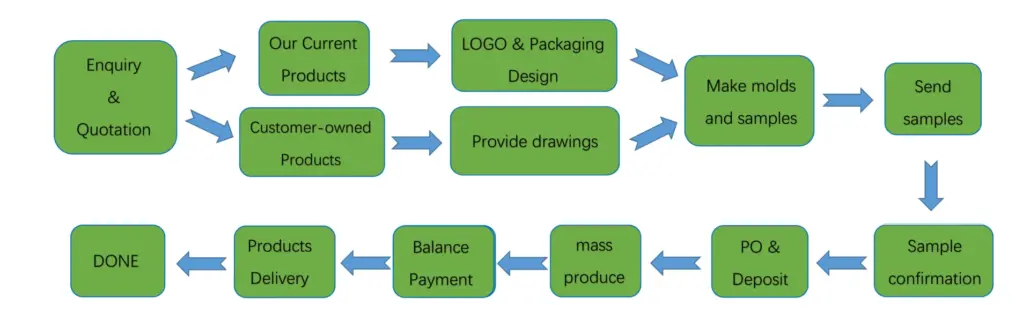

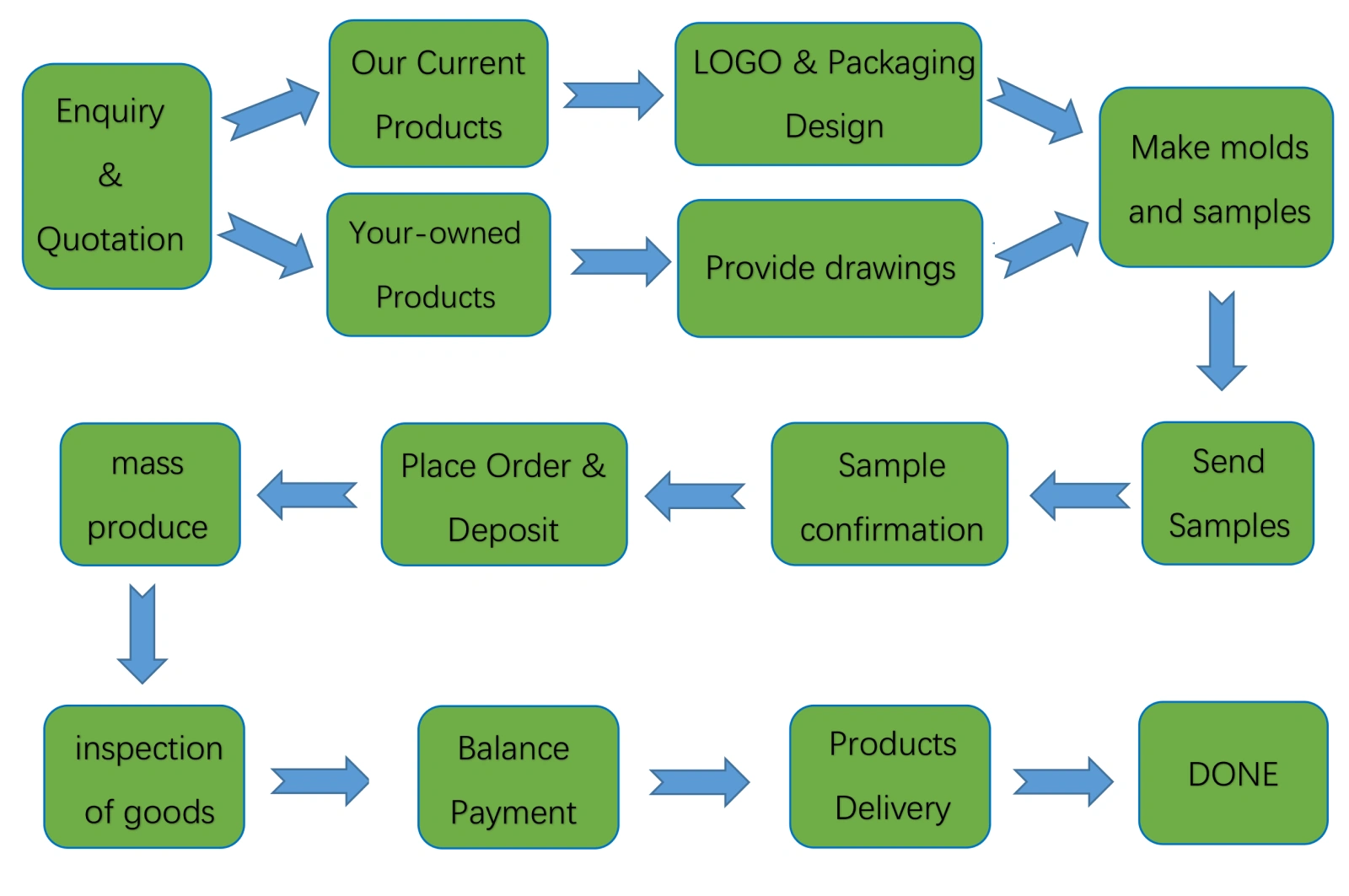

One Picture to know the OEM Process

As you know, the price of butterfly valve OEM requires relatively complex combination calculation, so if you have any questions, please contact us, we are always here.

Why Choose US

ABOUT US

ZFA VALVE OEM manufacturer Butterfly Valve Founded in 2006, mainly produce butterfly valves, valve parts compliance with international standard.

We have got ISO, CE, Wras certificates etc.

OEM Capacity

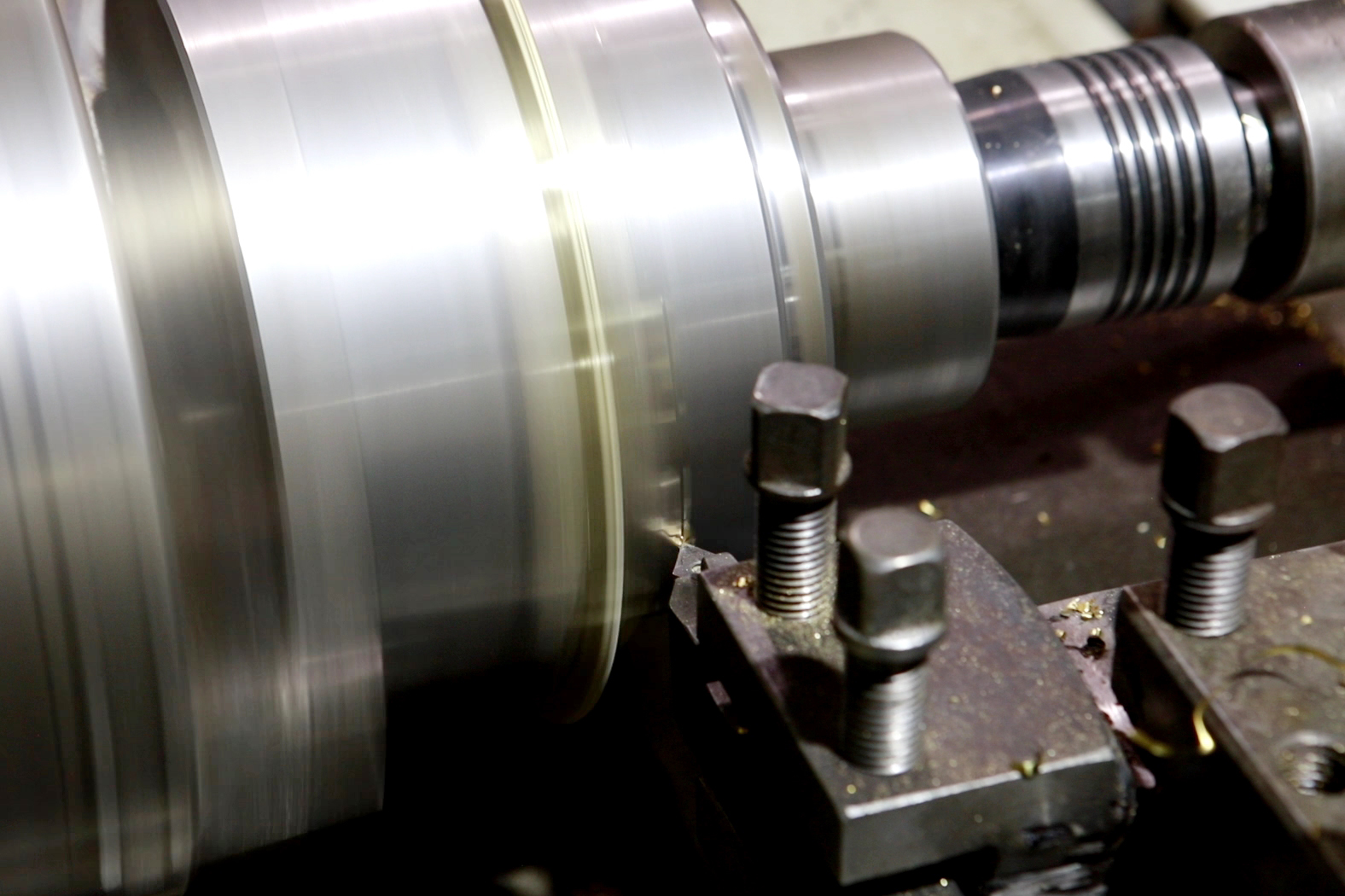

We have 32 machines (include CNC, machine center, semi-auto machine, pressure testing machine, etc.)

The most important is that we have tens of molds in hand, such as valve body, disc, handle molds.

Butterfly Valve Manufacturing Process

We’re a real butterfly valve factory with 17 years production experience, we’re OEM manufacturer butterfly valve for some customers around the world. All butterfly valves sold by ZFA VALVE are manufactured in our own factory. The excellent quality of our products comes from the meticulous management of the production process. ZFA VALVE is proud to show you our real production scene. Here is our motto: Rigorous production leads to excellent quality!

Step 1: Casting

Step 2:Material Preparation

Step 3:Material Quality Inspection

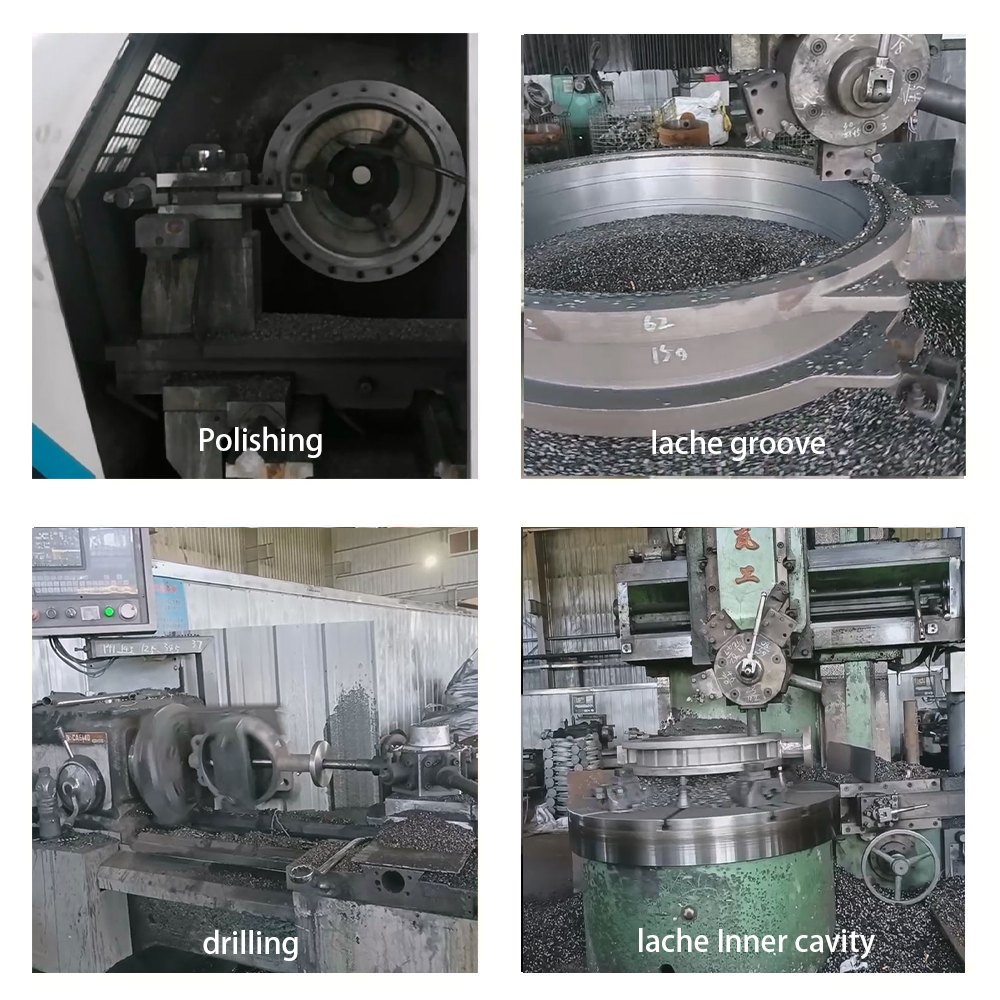

Step 4:Machining Parts

Step 5:Surface Treatment

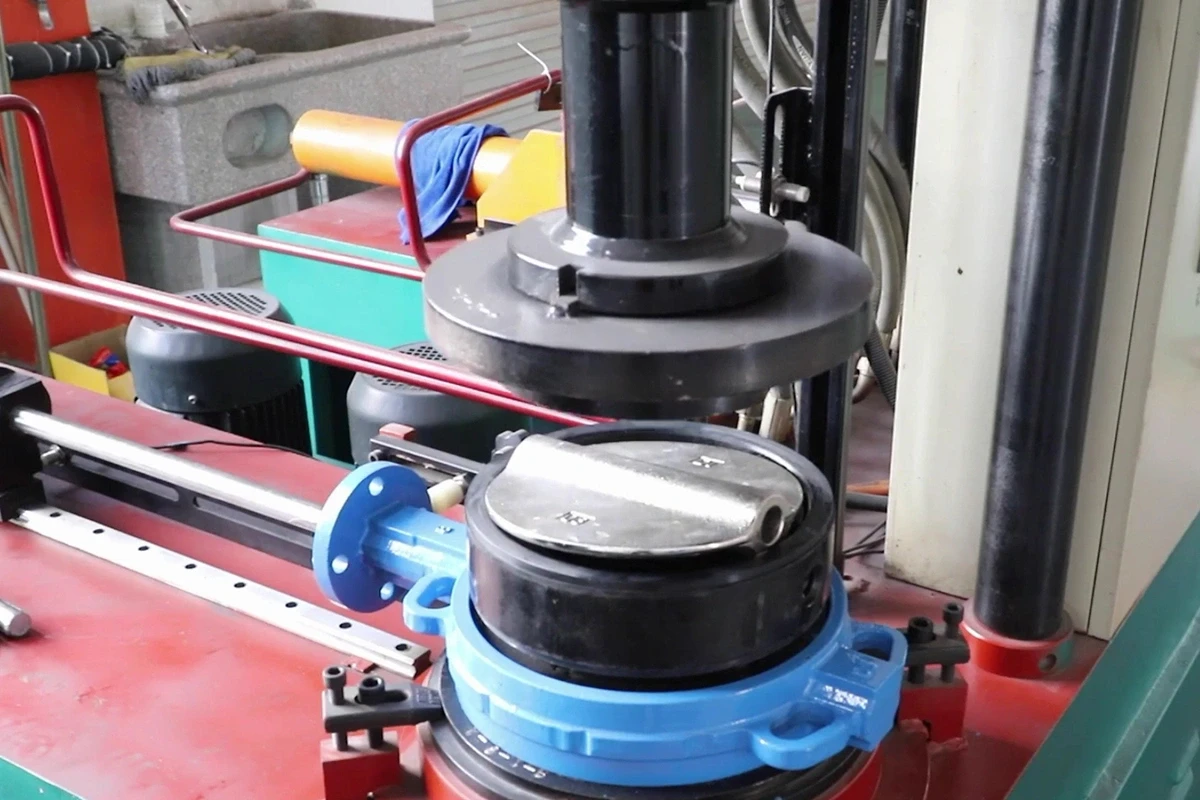

Step 6:Assembly

Step 7:Inspection And Quality Control

Step 8: Packaging

Step 9: Distribution

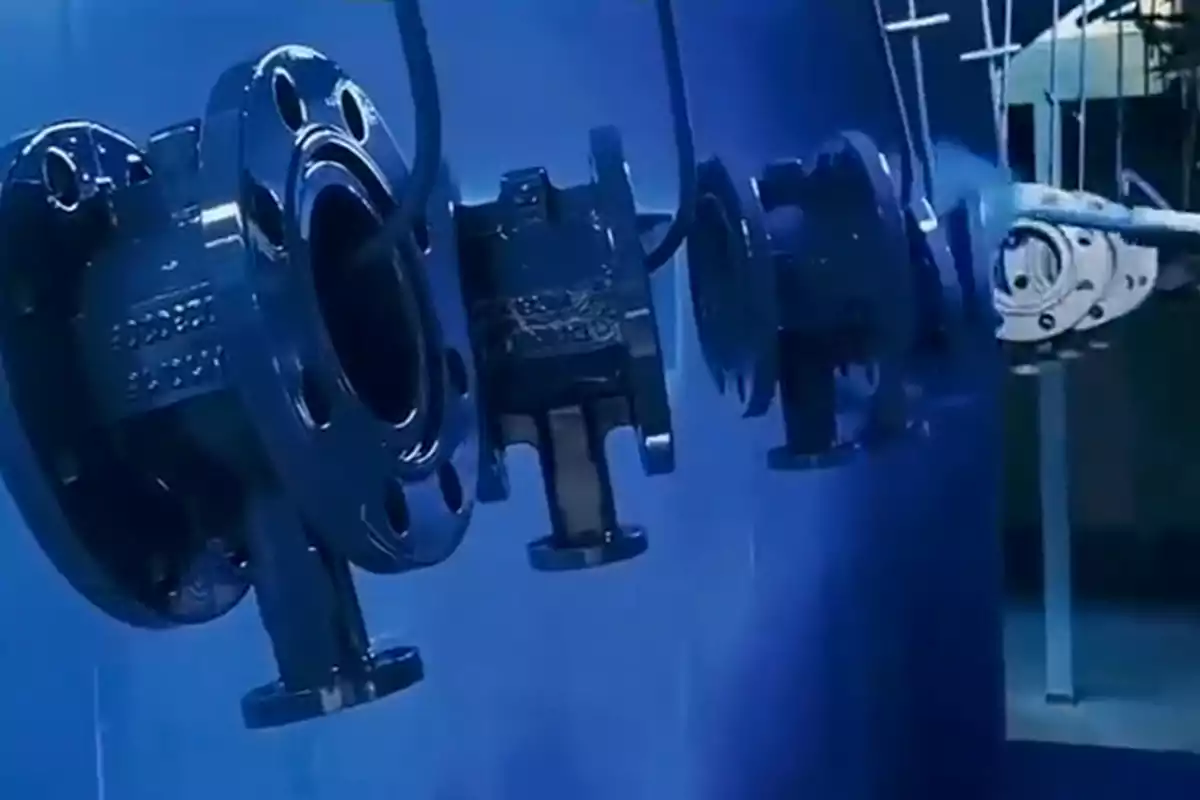

Producing Process of Butterfly Valve Parts

Valve Body of Butterfly Valve

Valve Disc of Butterfly Valve

Soft-backed Seat of Butterfly Valve

Factory Overview

Get More Videos about MANUFACTURING PROCESS, and CAD DAWING about the butterfly valve, please contact us!

Certificates