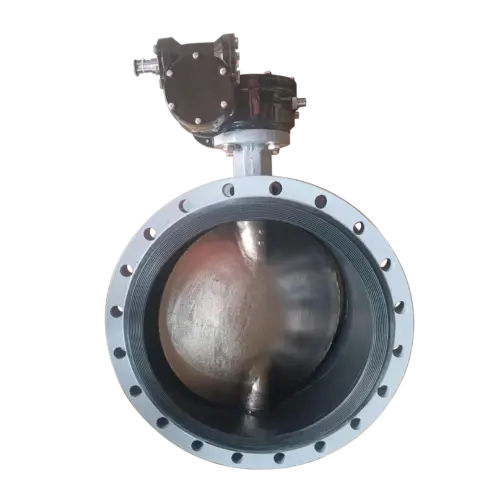

10K CF8 Body Polished CF8M Disc Soft Replaceable Silicone Seat Wafer Butterfly Valve

Basic Info of Silicone Seat Wafer Butterfly Valve

- JIS 10K is the Japanese standard pressure grade. This corresponds to a maximum working pressure of approximately 10 bar or 150 psi.

-

Silicone rubber valve seat butterfly valve can work stably in the temperature range of -10℃ to 160℃, and can withstand instantaneous temperature of 250 degrees.

-

Rubber Silicone has good corrosion resistance. Therefore, silicone valve seat butterfly valve can be used stably for a long time in a variety of chemical media.

-

Silicone has good flexibility and is not easy to break or crack. Therefore, silicone valve seat butterfly valve can achieve two-way sealing and 0 leakage.

- The CF8M (316 stainless steel) disc has excellent corrosion resistance, such as common acids and bases.

- The polished disc surface minimizes surface irregularities, further reducing the risk of pitting and crevice corrosion. The risk of media build-up is also reduced.

Silicone Seat Wafer Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Silicone Seat Wafer Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

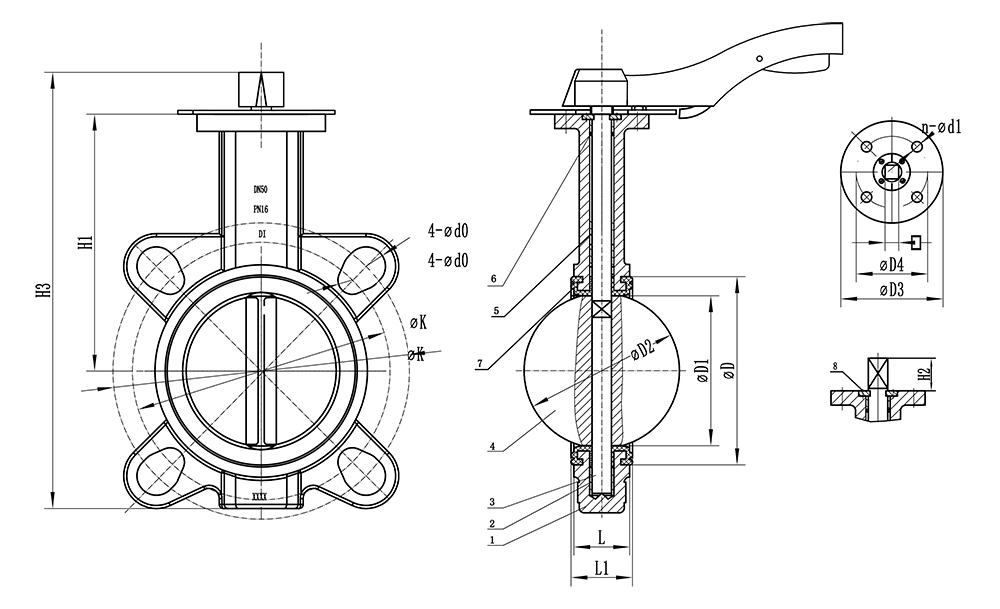

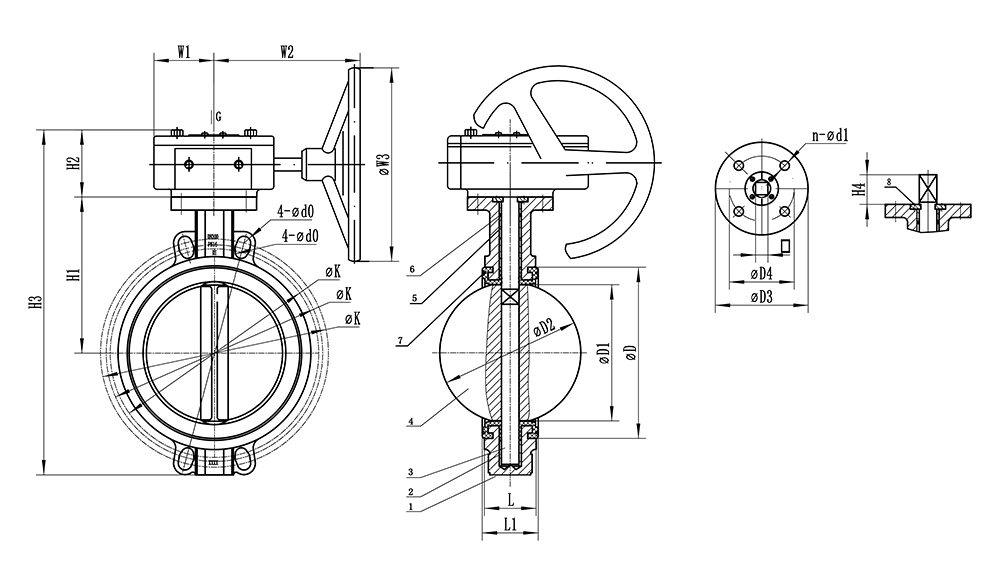

Paraments of Silicone Seat Wafer Butterfly Valve

| SIZE | D1 | D2 | D3 | N×φD | α° | F | G | A | B | C | E |

| DN50(2″) | 52.6 | 100 | 120.6 | 4×19 | 45 | 52 | 266.7 | 273 | 161 | 43 | 32 |

| DN100(4″) | 104 | 156 | 190.5 | 8×19 | 22.5 | 52 | 266.7 | 346 | 200 | 52.1 | 32 |

| DN150(6″) | 155.6 | 212 | 241.3 | 8×22. | 422.5 | 52 | 266.7 | 397 | 226 | 55.8 | 32 |

| DN200(8″) | 202.4 | 264 | 298.4 | 8×22. | 422.5 | 52 | 359 | 485 | 260 | 60.6 | 45 |

| SIZE | øK | 4-ød0 | øD | øD1 | øD2 | L | L1 | H1 | H2 | H3 | øD3 | øD4 | n-ød1 | □ | H4 | W1 | W2 | øW3 | |||||||

| PN6 | PN10 | PN16 | CL150 | PN6 | PN10 | PN16 | CL150 | ||||||||||||||||||

| DN200 | 8〞 | 280 | 295 | 295 | 298.5 | 4-ø19 | 4-ø23 | 4-ø23 | 4-ø22.3 | 246 | 194 | 202 | 60 | 64 | 235 | 86 | 487 | 125 | 102 | 4-012 | □17 | 35 | 75 | 238 | 300 |

| DN250 | 10〞 | 335 | 350 | 355 | 362 | 4-ø19 | 4-ø23 | 4-ø28 | 4-ø25.4 | 301.5 | 241 | 250 | 68 | 72 | 270 | 86 | 553 | 125 | 102 | 4-ø12 | □22 | 35 | 75 | 238 | 300 |

| DN300 | 12〞 | 395 | 400 | 410 | 431.8 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø25.4 | 352 | 290 | 301 | 78 | 83 | 310 | 118 | 658 | 25 | 102 | 4-ø12 | □22 | 35 | 81 | 227 | 300 |

| DN350 | 14〞 | 445 | 460 | 470 | 476.3 | 4-ø23 | 4-ø23 | 4-ø28 | 4-ø28.6 | 390 | 325.4 | 333.3 | 78 | 83 | 360 | 118 | 733 | 150 | 125 | 4-ø14 | □22 | 35 | 81 | 227 | 300 |

| DN400 | 16〞 | 495 | 515 | 525 | 539.8 | 4-ø23 | 4- ø 28 | 4-ø31 | 4-ø28.6 | 452 | 377 | 387 | 102 | 106 | 380 | 150 | 821 | 175 | 140 | 4-018 | □27 | 50 | 115 | 278 | 300 |

| DN500 | 20〞 | 600 | 620 | 650 | 635 | 4-ø23 | 4-ø28 | 4-ø34 | 4-ø31.8 | 564 | 480 | 491.6 | 127 | 132 | 470 | 150 | 981 | 175 | 140 | 4-ø18 | □27 | 50 | 115 | 278 | 300 |

| DN600 | 24〞 | 705 | 725 | 770 | 749.3 | 4-ø26 | 4-ø31 | 4-ø37 | 4-ø35 | 649.5 | 579.9 | 592.5 | 153 | 159 | 495 | 180 | 1120 | 210 | 165 | 4-022 | □36 | 60 | 144 | 304 | 300 |

Silicone Seat Wafer Butterfly Valve Applications

- Environmentally friendly and non-toxic: Silicone is a green and non-toxic material that does not contain toxic substances and will not cause harm to the environment and human body.

- Water treatment: used in water supply systems, wastewater treatment plants and other water-related processes.

- Drinking water and other systems: Silicone seat butterfly valves ensure a sanitary, leak-proof seal. They are suitable for drinking water pipes.

- HVAC systems: can control airflow in heating, ventilation and air conditioning systems.

- Chemical and pharmaceutical: Silicone rubber valve seats are ideal for industries that are resistant to corrosive chemicals.

- Food and Beverages: The cleanliness and non-corrosive materials of this valve make it suitable for food processing and beverage applications.

Silicone Seat Wafer Butterfly Valve Manufacture Process

ZFA Butterfly Valve Certificates

WRAS

CE

ISO 9001

EAC Russia