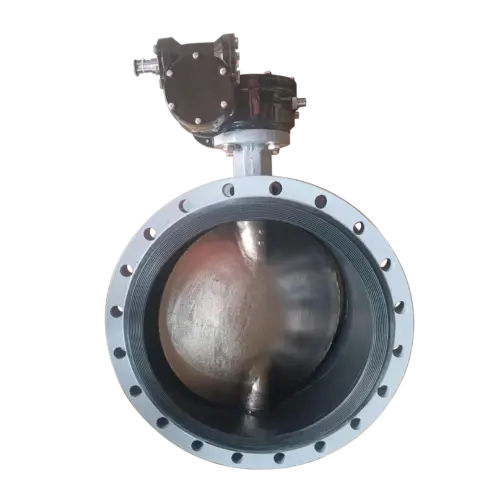

CF8M Disc PTFE Seat Anticorrosive Paint Lug Butterfly Valve

Features of Anticorrosive Paint Lug Butterfly Valve

- The anti-corrosion coating is the biggest highlight of this Anticorrosive Paint Lug Butterfly Valve. The paint provides an additional layer of protection for the butterfly valve body. It can support the long-term operation of the butterfly valve in harsh environments. And extend the butterfly valve’s service life in marine, industrial or high humidity conditions.

- CF8M disc, with excellent corrosion resistance, is especially suitable for chloride, acid and salt environments.

- PTFE seat has excellent chemical resistance, low friction and leak-proof sealing. Suitable for handling abrasive and corrosive fluids.

- Lug-type valve body: equipped with threaded inserts, it can achieve safe installation and easily isolate one side of the pipeline for maintenance without interrupting the entire system.

- The short structural length of Anticorrosive Paint Lug Butterfly Valve ensures space-saving installation and easy operation.

Standards of Anticorrosive Paint Lug Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Paraments of Anticorrosive Paint Lug Butterfly Valve

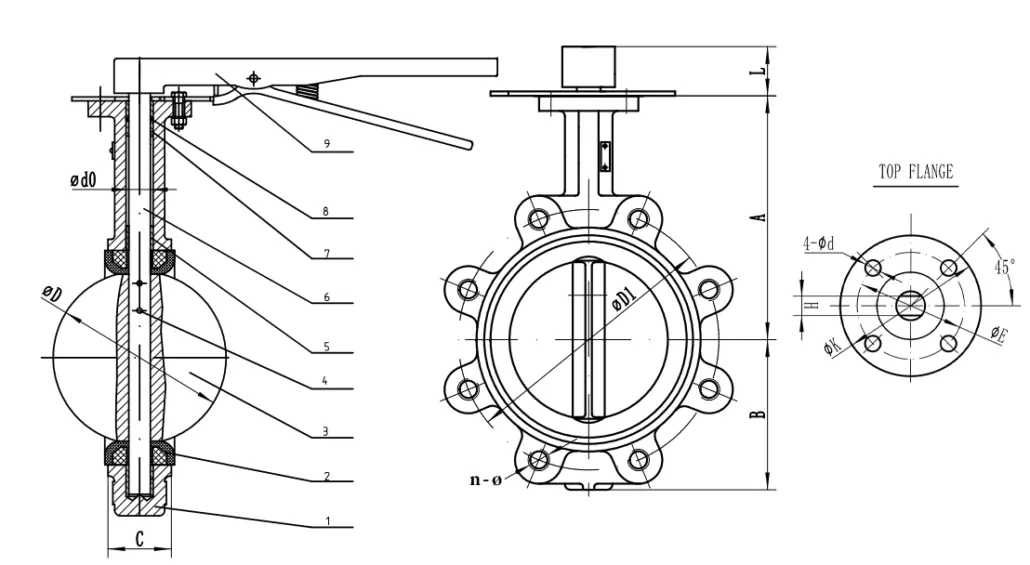

| DN | A | B | C | D | L | D1 | n-ø | K | E | 4-ød | d0 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | |||||||||||

| 50 | 2″ | 161 | 80 | 42 | 52.9 | 32 | 120 | 4-ø23 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 65 | 2.5″ | 175 | 89 | 44.7 | 64.5 | 32 | 136.2 | 4-ø26.5 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 80 | 3″ | 181 | 95 | 45.2 | 78.8 | 32 | 160 | 8-ø18 | 77 | 57.15 | 4-ø6.7 | 12.6 |

| 100 | 4″ | 200 | 114 | 52.1 | 104 | 32 | 185 | 4-ø24.5 | 92 | 69.85 | 4-ø10.3 | 15.77 |

| 125 | 5″ | 213 | 127 | 54.4 | 123.3 | 32 | 215 | 4-ø23 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 150 | 6″ | 226 | 139 | 55.8 | 155.6 | 32 | 238 | 4-ø25 | 92 | 69.85 | 4-ø10.3 | 18.92 |

| 200 | 8″ | 260 | 175 | 60.6 | 202.5 | 45 | 295 | 4-ø25 | 115 | 88.9 | 4-ø14.3 | 22.1 |

| 4-ø23 | ||||||||||||

| 250 | 10″ | 292 | 203 | 65.6 | 250.5 | 45 | 357 | 4-ø29 | 115 | 88.9 | 4-ø14.3 | 28.45 |

| 300 | 12″ | 337 | 242 | 76.9 | 301.6 | 45 | 407 | 4-ø29 | 140 | 107.95 | 4-ø14.3 | 31.6 |

| 350 | 14″ | 368 | 267 | 76.5 | 333.3 | 467 | 4-ø30 | 140 | 107.95 | 4-ø14.3 | 31.6 | |

| 400 | 16″ | 400 | 309 | 86.5 | 389.6 | 51.2 | 515 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 33.15 |

| 72 | 525 | 4-ø30 | ||||||||||

| 450 | 18″ | 422 | 328 | 105.6 | 440.51 | 51.2 | 565 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 38 |

| 72 | 585 | 4-ø30 | ||||||||||

| 500 | 20″ | 480 | 361 | 131.8 | 491.6 | 64.2 | 620 | 4-ø26 | 197 | 158.75 | 4-ø20.6 | 41.15 |

| 82 | 650 | 4-ø33 | ||||||||||

| 600 | 24″ | 562 | 459 | 152 | 592.5 | 70.2 | 725 | 20-ø30 | 276 | 215.9 | 4-ø22.2 | 50.65 |

| 82 | 770 | 20-ø36 | ||||||||||

| 700 | 28″ | 624 | 520 | 163 | 695 | 66 | 840 | 24-ø30 | 300 | 254 | 8-ø18 | 55/63.35 |

| 82 | 20-ø36 | |||||||||||

| 800 | 32″ | 672 | 591 | 188 | 794.7 | 66 | 950 | 24-ø33 | 300 | 254 | 8-ø18 | 55/63.35 |

| 82 | 24-ø39 | |||||||||||

| 900 | 36″ | 720 | 656 | 203 | 864.7 | 118 | 1050 | 24-ø33 | 300 | 254 | 8-ø18 | 75 |

| 1000 | 40″ | 800 | 721 | 216 | 965 | 142 | 1160 | 24-ø36 | 300 | 254 | 8-ø18 | 85 |

Applications of Anticorrosive Paint Lug Butterfly Valve

Due to its excellent corrosion resistance, this butterfly valve can be used in chemical processing plants, seawater treatment, oil and gas, pharmaceutical and power plant systems in addition to basic water treatment.

- Chemical Processing Plants:

-Handles acids, alkalis and corrosive chemicals without degradation.

-Suitable for applications involving sulfuric acid, hydrochloric acid and alkaline solutions. - Desalination:

-Can be used for wastewater, drinking water and desalination plants.

-Suitable for salt water and high chlorine environments. - Oil and Gas Industry

-For offshore and onshore facilities that are frequently exposed to seawater and harsh chemicals.

-Suitable for fuel handling and refined petroleum products. - Pharmaceutical and Food Industry

-PTFE valve seats provide a contamination-free flow path to ensure hygienic operation.

-For applications requiring clean, corrosion-resistant materials. - Marine and Shipbuilding

-Suitable for ballast water systems, seawater cooling and fire protection systems.

-Resistant to salt water corrosion. - Power Plants

-For cooling water systems, chemical metering lines and flue gas desulfurization (FGD) units.

-Resistant to high temperatures and corrosive chemicals.

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia