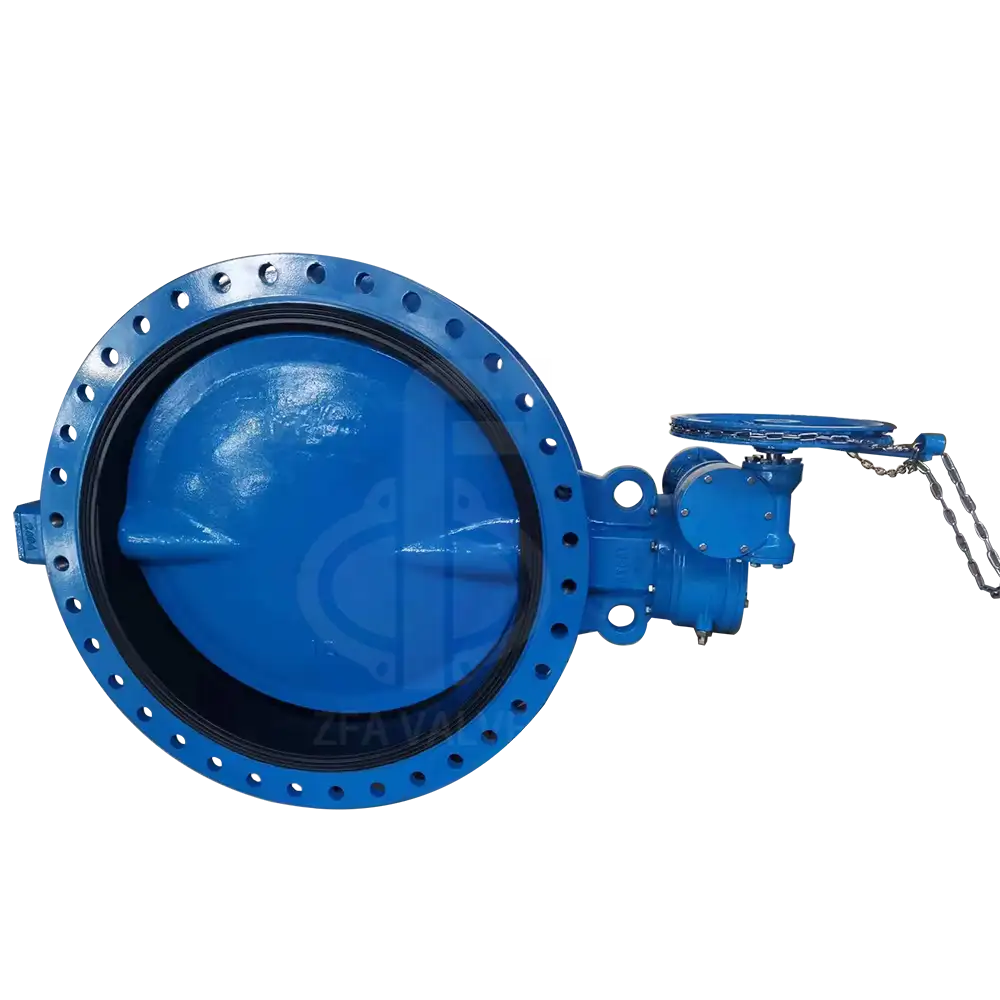

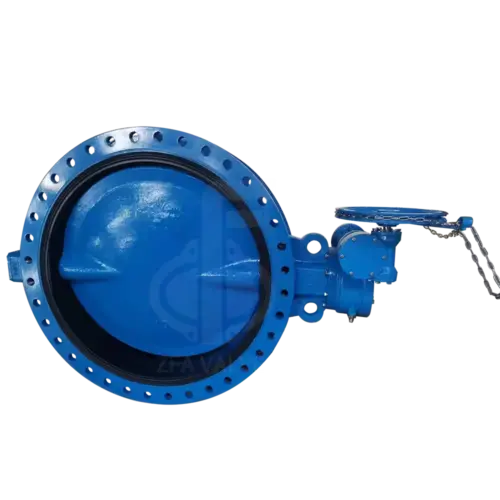

Chain Wheel Operated U Shape Butterfly Valves

Basic Info of Chain Wheel Butterfly Valves U Shape

- Chain wheel butterfly valve: it allows remote manual operation. It makes it easy to operate butterfly valves in hard-to-reach areas, like high places or tight spaces. The chain wheel butterfly valve is easily opened and closed by pulling the chain. Use sprocket operation if the handwheel’s center height exceeds 1800mm. But if DN is less than or equal to 40, sprockets are generally not used to avoid damaging the butterfly valve.

-

The U-shaped butterfly valve has a short, space-saving design. It is cheaper than a common flange butterfly valve.

- Rubber seat: It can be made of EPDM, NBR, PTFE, or other materials. This ensures a tight seal and fluid compatibility.

-

Replaceable seat ring: The Replaceable Seat Double Flanged Butterfly Valve has a replaceable seat. It can be easily replaced if it breaks, without replacing the entire valve.

-

Simple Installation: The Double Flanged Butterfly Valve is easy to install. Just place it between two flanged pipes or at the end of the pipe system.

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Worm Gear, Electric, Pneumatic | |||

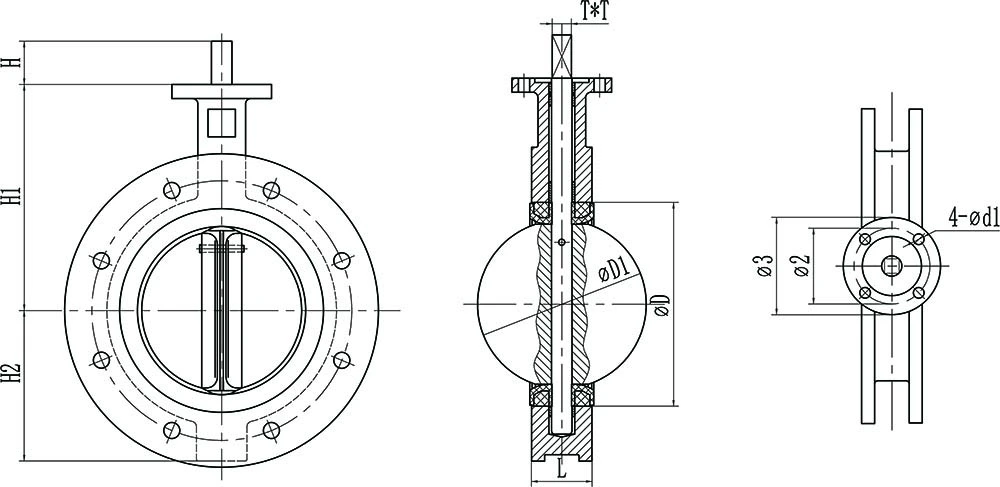

Paraments of U Shape Chain Wheel Butterfly Valves

| SIZE | øD | øD1 | L | H | H1 | H2 | ∅2 | ø3 | 4ødl | T*T |

| DN100 | 135 | 104.4 | 52 | 30 | 200 | 114 | 70 | 90 | 4-10 | 11*11 |

| DN125 | 159 | 123.3 | 56 | 30 | 213 | 127 | 70 | 90 | 4-10 | 14*14 |

| DN150 | 188.4 | 155.7 | 56 | 30 | 226 | 139 | 70 | 90 | 4-10 | 14*14 |

| DN200 | 238.2 | 202.5 | 60 | 40 | 260 | 175 | 102 | 125 | 4-12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68 | 40 | 292 | 203 | 102 | 125 | 4-12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78 | 45 | 337 | 242 | 102 | 125 | 4-12 | 22*22 |

| DN350 | 375.2 | 333.4 | 78 | 45 | 368 | 267 | 102 | 125 | 4-12 | 22*22 |

| DN400 | 439.5 | 389.6 | 102 | 52 | 400 | 309 | 140 | 175 | 4-18 | 27*27 |

| DN450 | 490.5 | 440.5 | 114 | 52 | 422 | 328 | 140 | 175 | 4-18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127 | 65 | 480 | 360 | 140 | 175 | 4-18 | 36*36 |

| DN600 | 654.3 | 592.5 | 154 | 70 | 562 | 456 | 165 | 210 | 4-22 | 36*36 |

Manufacture Process of Butterfly Valves

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia