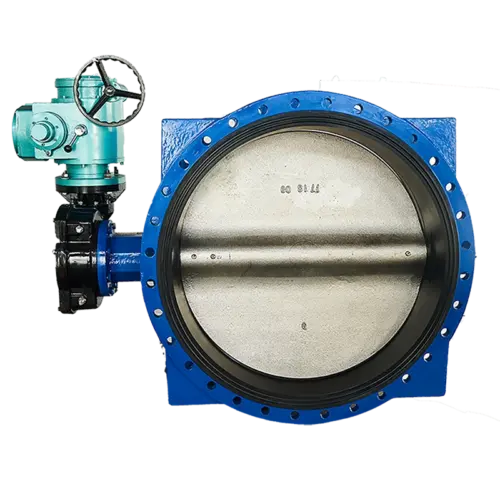

Ducitle Iron Wafer Butterfly Valve With Worm Gear

Basic Info

- Reliable sealing: The wafer butterfly valve is equipped with a high-quality sealing system, ensuring leak-proof operation and preventing any unwanted fluid or gas leakage.

- Excellent throttling capability: The worm gear mechanism allows for precise control of the valve opening, enabling efficient throttling and flow regulation.

- Easy operation: The worm gear design provides smooth and effortless operation, allowing for easy opening and closing of the valve even in applications with high pressure or temperature.

- Long service life: The ductile iron construction offers exceptional durability and resistance to wear, ensuring a long service life even in demanding environments.

- Wide range of sizes and pressure ratings: The butterfly valve is available in various sizes and pressure ratings, allowing for flexibility in installation and compatibility with different piping systems.

- Versatile application: The wafer butterfly valve can be used in a wide range of industries and applications, including water treatment, HVAC systems, chemical processing, and industrial processes, where reliable flow control is essential.

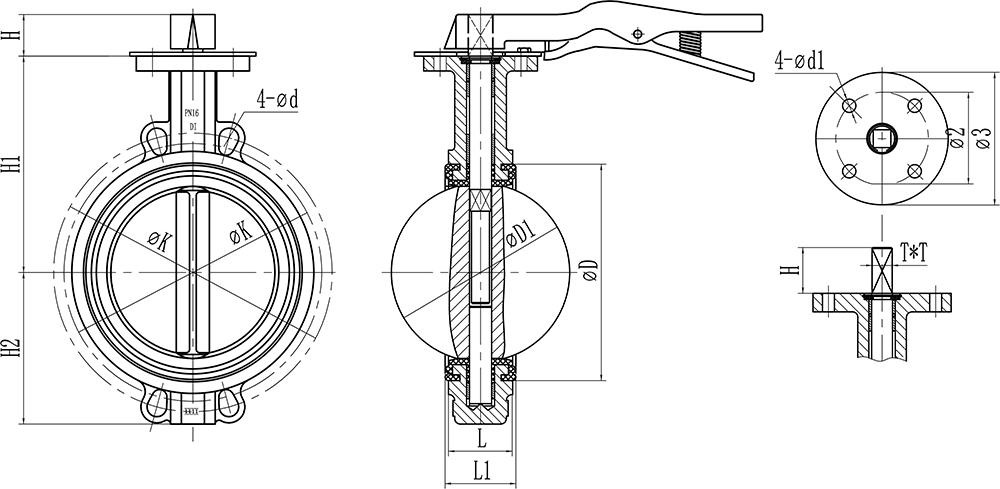

Paraments

| SIZE | øK | 4-ød | øD | øD1 | L | L1 | H | H1 | H2 | ø2 | ø3 | 4-ødl | T*T | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN6 | PN10 | PN16 | CL150 | PN6 | PN10 | PN16 | CL150 | ||||||||||||

| DN50 | 110 | 125 | 120.6 | 4-ø14 | 4-ø19 | 4-ø19 | 82 | 53.08 | 42.5 | 46.1 | 30 | 140 | 60 | 70 | 90 | 10 | 11 | ||

| DN65 | 130 | 145 | 139.7 | 4-ø14 | 4-ø19 | 4-ø19 | 94 | 64.82 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11 | ||

| DN80 | 150 | 160 | 152.4 | 4-ø19 | 8-ø19 | 4-ø19 | 111.2 | 79.04 | 45.6 | 48.4 | 30 | 160 | 87 | 70 | 90 | 10 | 11 | ||

| DN100 | 170 | 180 | 190.5 | 4-ø19 | 8-ø19 | 8-ø19 | 140 | 104.04 | 52 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11 | ||

| DN125 | 200 | 210 | 215.9 | 8-ø19 | 8-ø19 | 8-ø22.4 | 166 | 123.3 | 56 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14 | ||

| DN150 | 225 | 240 | 241.3 | 8-ø19 | 8-ø23 | 8-ø22.4 | 187 | 155.68 | 56 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14 | ||

| DN200 | 280 | 295 | 298.4 | 8-ø19 | 8-ø23 | 12-ø23 | 8-ø22.4 | 246.8 | 201.9 | 60 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17 | |

| DN250 | 335 | 350 | 355 | 361.9 | 12-ø19 | 12-ø23 | 12-ø28 | 12-ø25.4 | 301.5 | 250.45 | 68 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 395 | 400 | 410 | 431.8 | 12-ø23 | 12-ø23 | 12-ø28 | 12-ø25.4 | 352 | 301.55 | 78 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

Manufacture Process