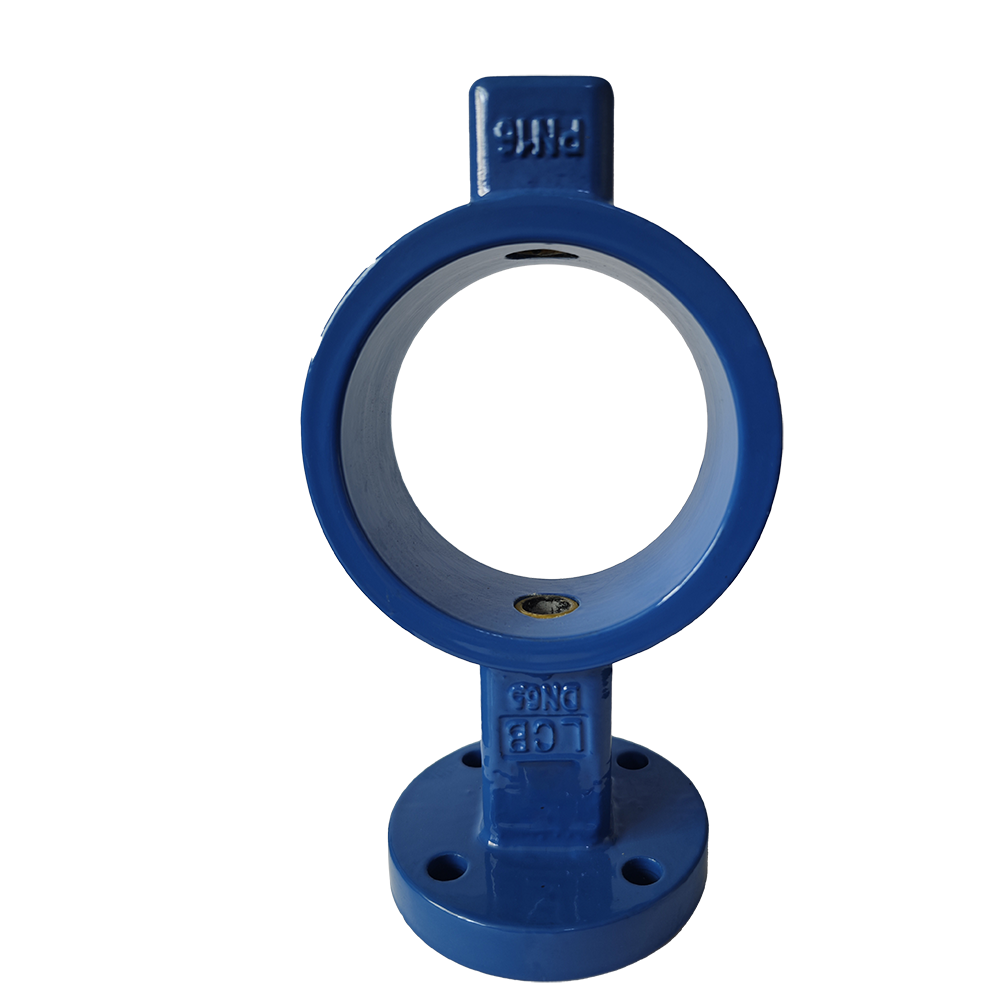

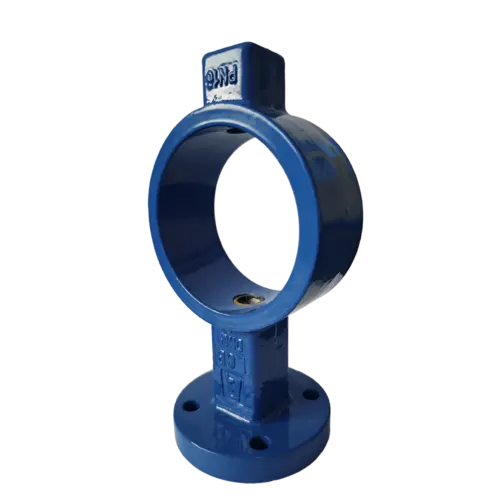

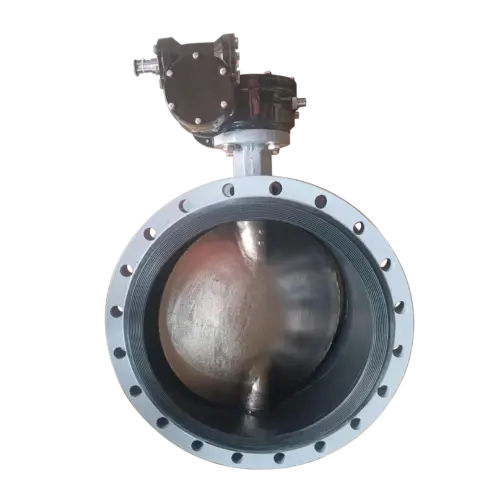

Hard Back Seat Soft Seal LCB Wafer Butterfly Valve

Basic Info of LCB wafer butterfly valve

The LCB wafer butterfly valve is made of cryogenic steel-low-temperature steel. It is a type of steel specifically designed to work in low-temperature environments.

Its advantages include:

- Excellent low-temperature toughness: LCB can maintain good toughness and strength at extremely low temperatures. It allows to work normally in extremely cold environments.

- Suitable for low-temperature processes: LCB is widely used in low-temperature processes such as liquefied natural gas (LNG) and liquefied petroleum gas (LPG).

However, low temperature steel LCB wafer butterfly valve also has some disadvantages, such as:

-Higher cost: Since LCB needs to have excellent low-temperature properties and corrosion resistance. Its manufacturing cost is usually higher.

-Difficulty in processing: Due to the special performance requirements of low-temperature steel, it may be more difficult to process. It requires higher processing and welding processes.

-Poor weldability: Some special types of low-temperature steel may have certain difficulties in welding and require special welding processes and materials.

Technical Parameters of LCB wafer butterfly valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Hand lever, Worm Gear, Electric, Pneumatic |

Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

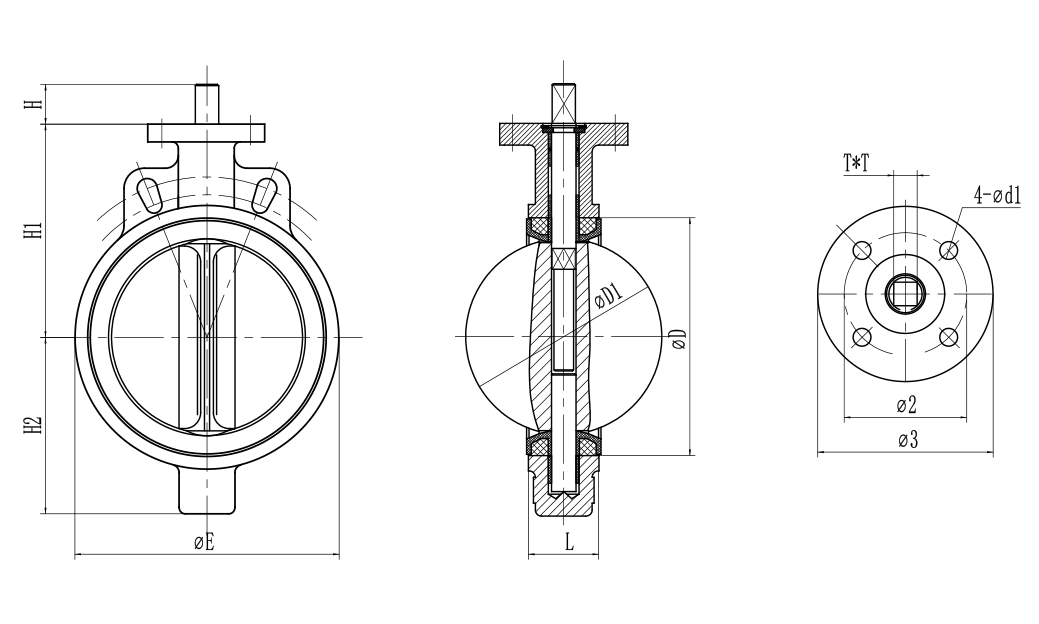

Drawing and Dimension

| SIZE | øD | øD1 | L | H | WCB | GGG40 | ø2 | ø3 | 4-ød1 | T*T | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | øE | H1 | H2 | øE | |||||||||

| DN50 | 76.3 | 52.8 | 43 | 30 | 113 | 73 | 95 | 115 | 74 | 100 | 70 | 90 | 10 | 11*11 |

| DN65 | 89 | 64.6 | 46 | 30 | 120 | 80 | 108 | 123 | 81 | 121 | 70 | 90 | 10 | 11*11 |

| DN80 | 103.9 | 79.1 | 46 | 30 | 128 | 87 | 126 | 130 | 90 | 129 | 70 | 90 | 10 | 11*11 |

| DN100 | 135 | 104.4 | 52 | 30 | 147 | 103 | 151 | 148 | 108 | 162 | 70 | 90 | 10 | 11*11 |

| DN125 | 159 | 123.3 | 56 | 30 | 160 | 116 | 181 | 161 | 118 | 193 | 70 | 90 | 10 | 14*14 |

| DN150 | 188.4 | 155.6 | 56 | 30 | 176 | 138 | 208 | 178 | 139 | 245 | 102 | 125 | 12 | 14*14 |

| DN200 | 238.2 | 202.5 | 60 | 40 | 200 | 162 | 262 | 200 | 163 | 271 | 102 | 125 | 12 | 17*17 |

| DN250 | 292.4 | 250.5 | 68 | 40 | 244 | 202 | 318 | 246 | 204 | 322 | 102 | 125 | 12 | 22*22 |

| DN300 | 344.2 | 301.6 | 78 | 45 | 275 | 222 | 376 | 272 | 229 | 379 | 125 | 150 | 14 | 22*22 |

| DN350 | 375.2 | 333.4 | 78 | 45 | 315 | 270 | 419 | 314 | 269 | 436 | 125 | 150 | 14 | 22*22 |

| DN400 | 439.5 | 389.6 | 102 | 52 | 364 | 305 | 485 | 365 | 321 | 491 | 140 | 175 | 18 | 27*27 |

| DN500 | 535.4 | 491.6 | 127 | 65 | 412 | 374 | 591 | 413 | 369 | 591 | 140 | 175 | 18 | 36*36 |

| DN600 | 653.7 | 592.5 | 154 | 70 | 495 | 440 | 728 | 495 | 437 | 728 | 165 | 210 | 22 | 36*36 |

Manufacture Process

Certificates

WRAS

CE

ISO 9001

EAC Russia