NBR Seat CF3MN Disc 14 Fully Lug Butterfly Valve

Features of CF3MN lug butterfly valve

- CF3MN is DIN 1.4429, JIS SUS316LMN.

-

CF3MN is a high-alloy stainless steel with excellent corrosion resistance. It is especially suitable for working environments containing acidic or alkaline media.

-

CF3MN material has high temperature resistance. So it can operate stably for a long time in high temperature environments without failure.

-

CF3MN material has good mechanical properties, high strength and toughness. Besides, it can withstand high pressure and high flow working conditions.

- 14 lug butterfly valves refers to DN350, 14inch, and the connecte type is lug, which is more stable than wafer butterfly valves.

- The Worm gear operated type lug butterfly valve provides mechanical advantage, making people easier to operate the valve, especially in larger sizes or higher-pressure applications.

Furthermore, the CF3MN lug butterfly valve has a NBR seat, this material is as non-toxic and odorless as CF3MN. so the lug butterfly valve meets environmental protection requirements, and is safe and reliable to use. Therefore, it can be used in drinking water, sewage and other treatment. It can also be used in chemical industry, petroleum, natural gas, and other fields to meet different industrial needs.

Standard of CF3MN lug butterfly valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

CF3MN lug butterfly valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

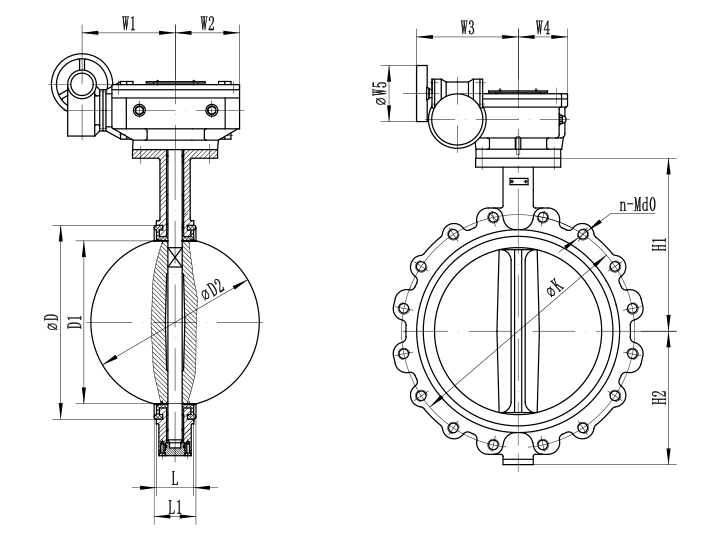

Paraments of CF3MN lug butterfly valve

| SIZE | ∅K | n-Md0 | ∅D | D1 | øD2 | L | L1 | H1 | H2 | W1 | W2 | øW3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN350 | 476.3 | 12-1″-8NUC | 390 | 325.4 | 333.3 | 78 | 83 | 360 | 255 | 81 | 227 | 300 |

| DN400 | 539.8 | 16-1″-8NUC | 452 | 377 | 387 | 102 | 106 | 380 | 291 | 178 | 121 | 278 |

| DN500 | 635 | 20-1 1/8″-7NUC | 564 | 480 | 491.6 | 127 | 132 | 470 | 361 | 178 | 121 | 278 |

| DN600 | 749.3 | 20-1 1/4″-7NUC | 649.5 | 579.9 | 590 | 153 | 159 | 495 | 445 | 198 | 142 | 304 |

Manufacture Process of Lug Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia