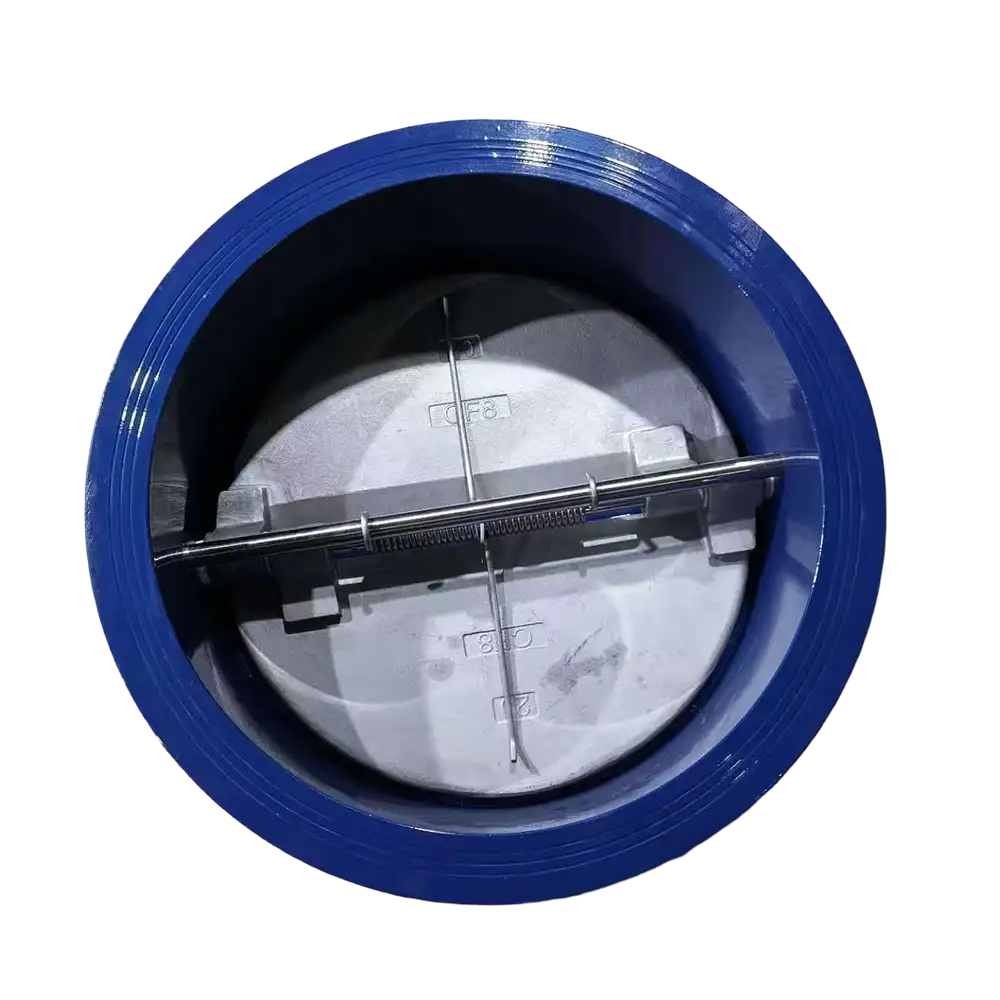

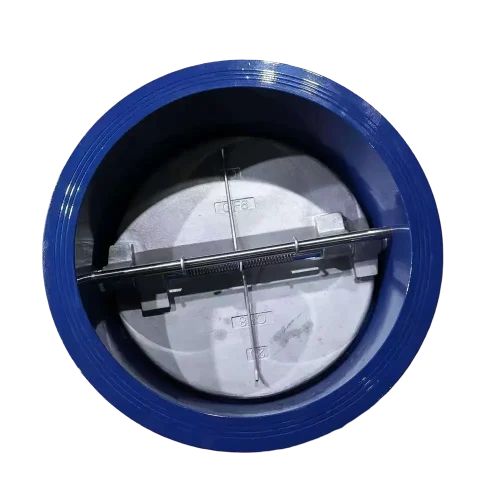

150LB 30inch WCB Double Door Wafer Check Valve One Way Valve

Paraments of Double Door Wafer Butterfly Valve

- 150LB: Pressure Rating Rated for 150 PSI (per ASME B16.34), this valve suits medium-pressure applications in water, oil, gas, or steam systems. Its pressure class balances durability with versatility.

- WCB: The valve body is made of WCB (ASTM A216 cast carbon steel). Suitable for non-corrosive environments, WCB is cost-effective for general service.

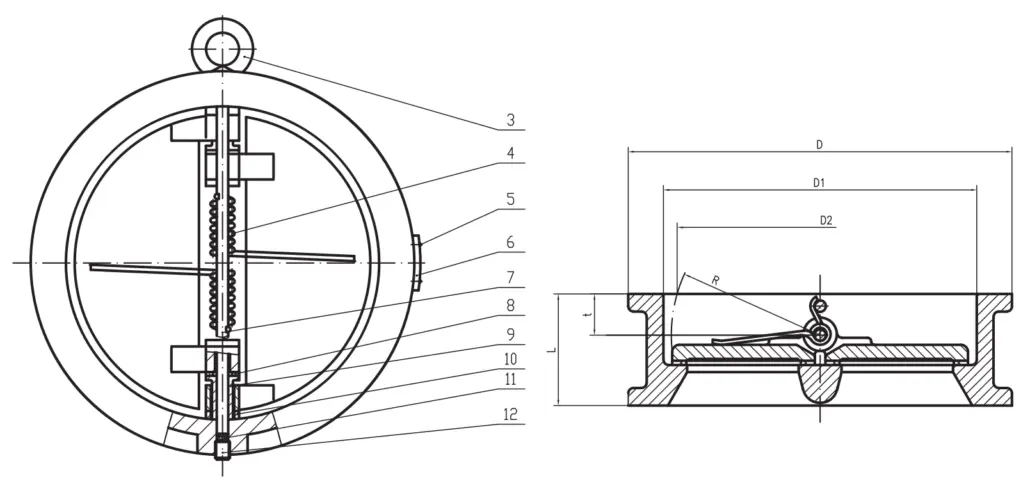

- Double Door one way Valve Design: Features two spring-loaded, hinged discs that open with forward flow and snap shut instantly against reverse flow. The wafer-style installation fits between ANSI/ASME B16.5 flanges, eliminating the need for separate flange bolts and reducing weight.

- Compact and Lightweight: The wafer design saves space and simplifies installation compared to traditional swing check valves, which is critical for large 30-inch systems.

| DN | D | D1 | D2 | L | R | t | |

|---|---|---|---|---|---|---|---|

| mm | inch | ||||||

| 50 | 2″ | 107 | 65 | 43.3 | 43 | 28.2 | 19 |

| 65 | 2.5″ | 127 | 80 | 60.2 | 46 | 36.1 | 20 |

| 80 | 3″ | 142 | 94 | 66.4 | 64 | 43.4 | 28 |

| 100 | 4″ | 162 | 117 | 90.8 | 64 | 52.8 | 27 |

| 125 | 5″ | 192 | 145 | 116.9 | 70 | 65.7 | 30 |

| 150 | 6″ | 218 | 170 | 144.6 | 76 | 78.6 | 31 |

| 200 | 8″ | 273 | 224 | 198.2 | 89 | 104.4 | 33 |

| 250 | 10″ | 328 | 265 | 233.7 | 114 | 127 | 50 |

| 300 | 12″ | 378 | 310 | 283.9 | 114 | 148.3 | 43 |

| 350 | 14″ | 438 | 360 | 332.9 | 127 | 172.4 | 45 |

| 400 | 16″ | 489 | 410 | 381 | 140 | 197.4 | 52 |

| 450 | 18″ | 539/555 | 450 | 419.9 | 152 | 217.8 | 58 |

| 500 | 20″ | 594 | 505 | 467.8 | 152 | 241 | 58 |

| 600 | 24″ | 690 | 624 | 572.6 | 178 | 295.4 | 73 |

| 700 | 28″ | 800 | 720 | 680 | 229 | 354 | 98 |

Applications of Double Door One Way Valve

- Water Treatment Plants: Prevents backflow in pump discharge lines.

- Oil and Gas Pipelines: Safeguards equipment from reverse flow in hydrocarbon transport.

- HVAC Systems: Manages steam or chilled water in large commercial setups.

- Power Generation: Used in cooling water or condensate systems.

Advantages of Dual Disc Check Valve.

- Quick Closure: Spring-assisted discs minimize water hammer and protect pumps.

- Low Maintenance: No lubrication required; resistant to wear in high-flow conditions.

- Cost-Effective: Reduced material and installation costs due to wafer design.

Installation Tips of One Way Flow Valve

- Ensure proper flange alignment (ASME B16.5) and gasket integrity for leak-free performance.

- Install horizontally or vertically, but verify spring tension for optimal disc movement.

- Inspect discs periodically for debris or wear in high-sediment environments.