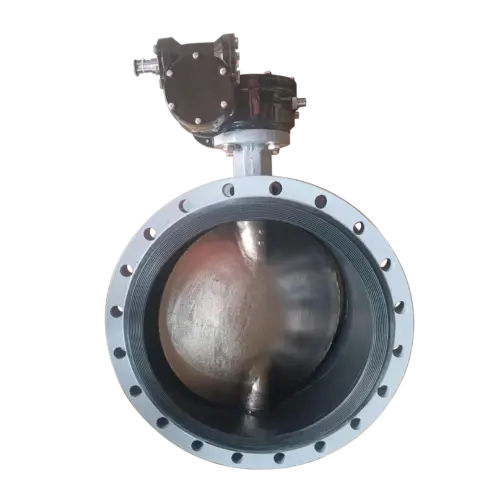

PTFE Seat Stainless Steel Wafer Butterfly Valve

Basic Info

- The material selection of stainless steel wafer butterfly valve in accordance with relevant standards, and refuses to cut corners.

- Standard structure,Thick casting,Quick and light opening and closing, convenient maintenance.

- Strong corrosion resistance: The PTFE lining is not easily eroded by corrosive media such as acids and alkalis, so it can maintain the service life of the valve body.

- Application fields: PTFE lining is not only suitable for liquid media, but also suitable for fluid control in various working conditions such as gas and steam.

- Good stability: PTFE lining can fix the internal rubber and prevent it from deforming during use.

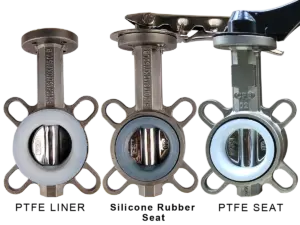

Following is the difference between PTFE Liner, Silicone Rubber Seat and PTFE Seat wafer butterfly valve.

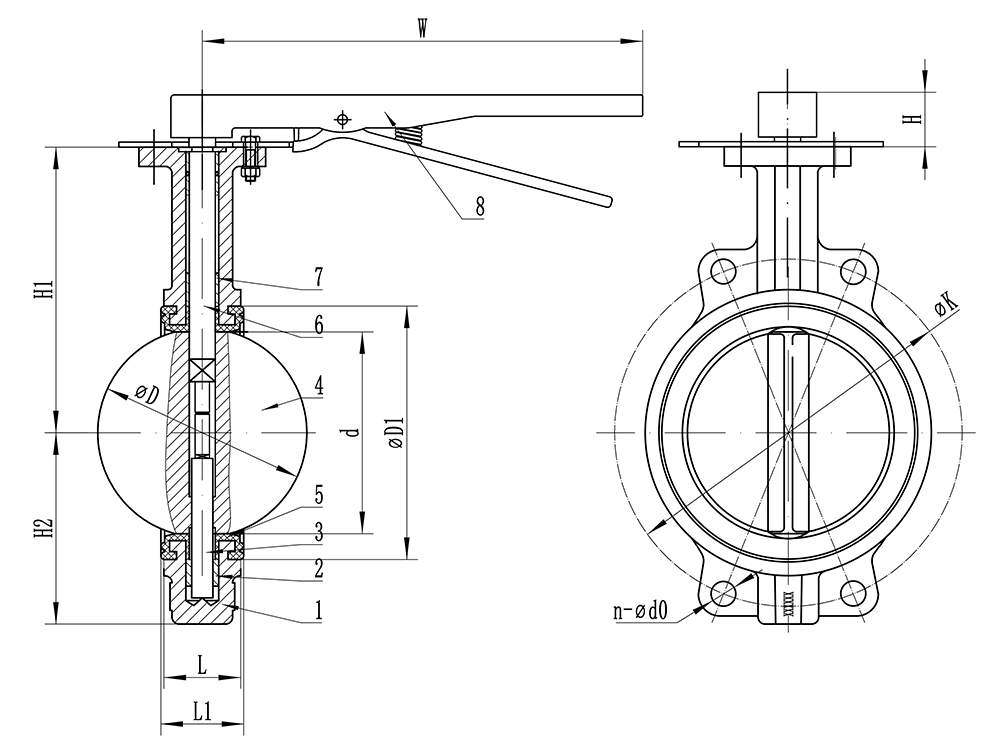

Paraments

DN50-DN200

| SIZE | ∅D | øK | n-∅d0 | øD1 | d | L | L1 | H | H1 | H2 | W |

| DN50 | 53 | 120.7 | 4-∅19 | 76.3 | 45 | 43 | 46 | 25 | 140 | 64 | 170 |

| DN65 | 64.5 | 139.7 | 4-ø19 | 94 | 59.4 | 45.6 | 49 | 25 | 143 | 80 | 170 |

| DN100 | 104 | 190.5 | 4-∅19 | 135 | 97 | 52.1 | 56 | 25 | 170 | 96.7 | 215 |

| DN125 | 123.2 | 215.9 | 4-∅22.4 | 166 | 117 | 56 | 60 | 25 | 190 | 117 | 215 |

| DN150 | 156 | 241.3 | 4-∅22.4 | 188.4 | 146.3 | 56 | 60 | 25 | 210 | 137 | 215 |

| DN200 | 202 | 298.5 | 4-ø22.4 | 238.2 | 193.7 | 60 | 64 | 35 | 235 | 168 | 265 |

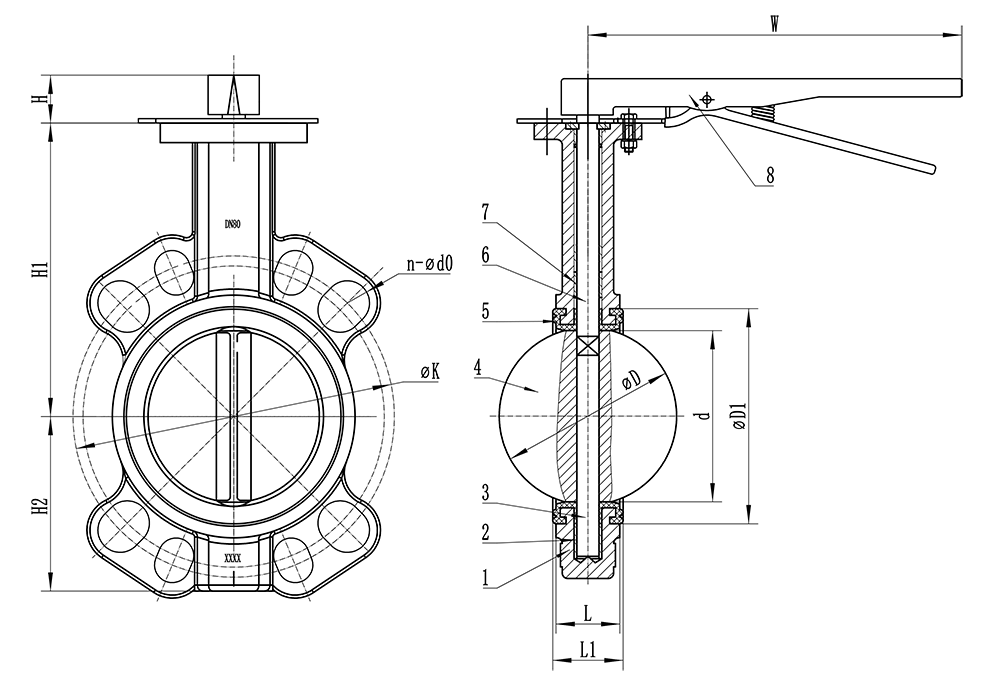

DN80

| SIZE | ∅D | øK | n-∅d0 | øD1 | d | L | L1 | H | H1 | H2 | W |

| DN80 | 77.3 | 152.4 | 4-∅19 | 103.9 | 78 | 45.2 | 49.3 | 25 | 155 | 94.4 | 170 |

Manufacture Process

Certificates