PTFE Seat Hard Seat Back Wafer Butterfly Valve Introduction

The PTFE seat butterfly valve is designed for industrial applications requiring corrosion resistance and durability. It features strong corrosion resistance overall. The PTFE valve seat ensures good sealing performance and a wide temperature range. The hardback seat provides structural support. Its compact structure and light weight make it ideal for various industrial uses.

PTFE Seat Hard Seat Back Wafer Butterfly Valve Advantages

Compared to the EPDM Seat butterfly valve, the PTFE Seat butterfly valve has more advantages.

- Corrosion resistance: PTFE has excellent corrosion resistance to various corrosive liquids, including strong acids, strong alkalis, etc.

- Temperature Range: PTFE can withstand higher temperatures than EPDM, while It has a temperature range of approximately -250°C to +260°C (-418°F to +500°F).

- Versatility: PTFE is also called “Plastic King” in China, so it is suitable for different types of media, whether corrosive or non-corrosive fluid.

- Low Friction: PTFE has a low coefficient of friction, reducing wear on valve components. As a result, it can increase service life and reduce maintenance.

- Universal Sealing Material: PTFE is a universal sealing material compatible with various flanges and gaskets.

PTFE Seat Hard Seat Back Wafer Butterfly Valve Parts

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

PTFE Seat Hard Seat Back Wafer Butterfly Valve Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Hard Seat Back PTFE Seat Wafer Butterfly Valve Applications

- Chemical Processing:due to the resistance to chemical of PTFE seat, so this butterfly valve is an ideal valve for industries chemicals.

- Water Treatment:The most common application of butterfly valves is water treatment. Of course. This PTFE seat butterfly valve can be also used in clean and corrosion-free operation systems.

- HVAC Systems:For use in heating and cooling systems where precise flow control is required.

- FoodProcessing: Food-grade butterfly valves are particularly suitable for handling liquid media such as milk, juice, beer, drinking water, syrup, and are used in fermentation, mixing, and cleaning.

Paraments Of PTFE Seat Wafer Butterfly Valve

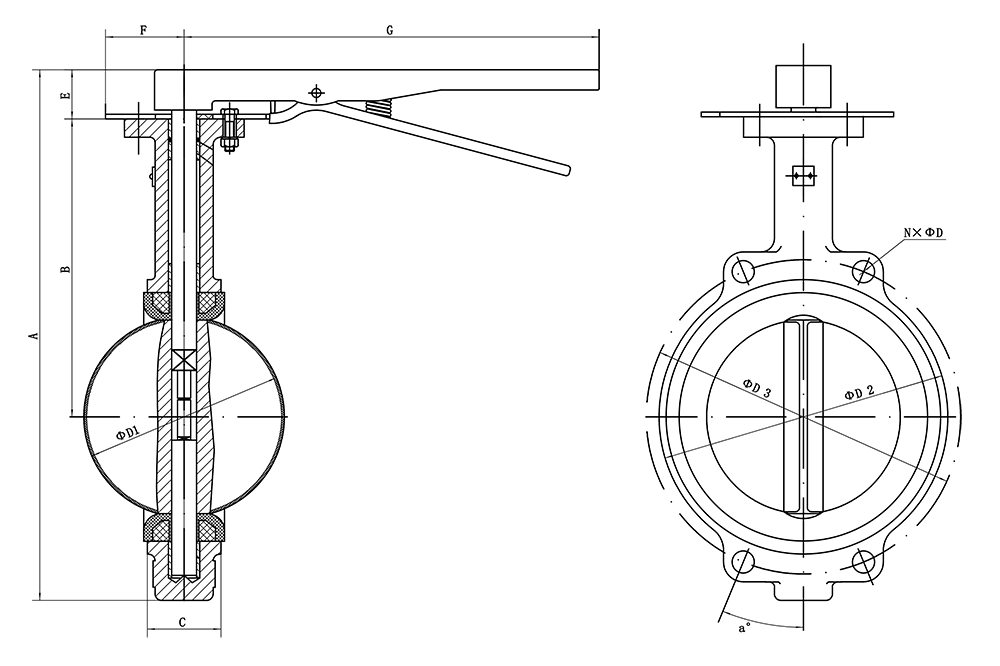

DN50-DN200

| SIZE | D1 | D2 | D3 | N×φD | α° | F | G | A | B | C | E |

| DN50(2″) | 52.6 | 100 | 120.6 | 4×19 | 45 | 52 | 266.7 | 273 | 161 | 43 | 32 |

| DN100(4″) | 104 | 156 | 190.5 | 8×19 | 22.5 | 52 | 266.7 | 346 | 200 | 52.1 | 32 |

| DN150(6″) | 155.6 | 212 | 241.3 | 8×22.4 | 422.5 | 52 | 266.7 | 397 | 226 | 55.8 | 32 |

| DN200(8″) | 202.4 | 264 | 298.4 | 8×22.4 | 422.5 | 52 | 359 | 485 | 260 | 60.6 | 45 |

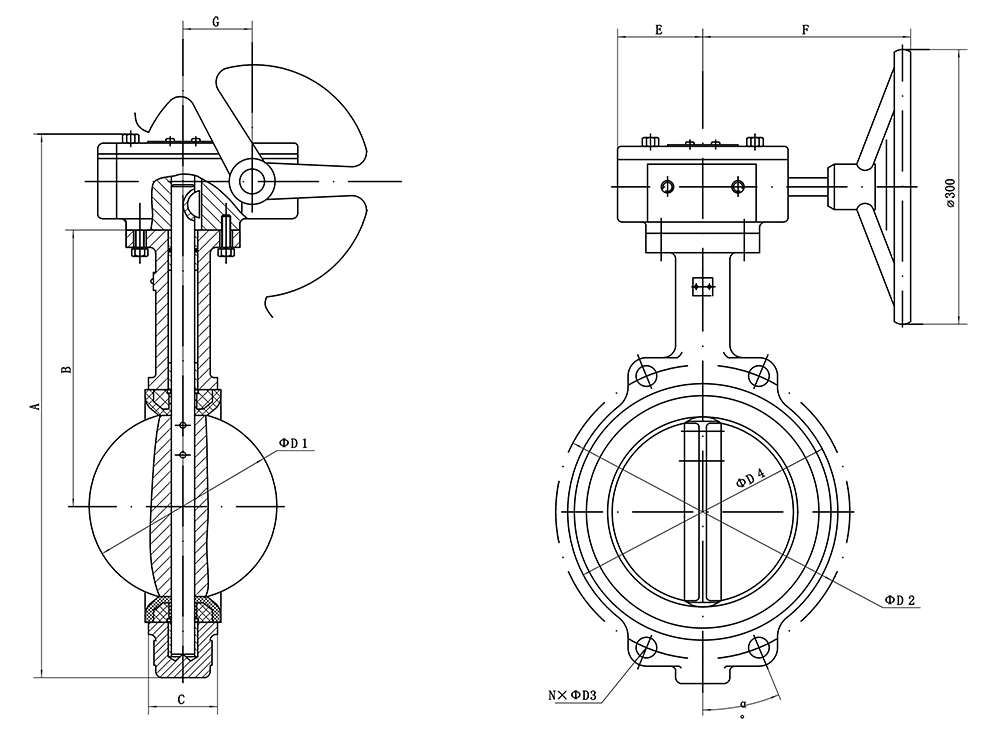

DN200-DN350

| SIZE | A | B | C | D1 | D2 | N×D3 | α ° | D4 | E | F | G |

| DN200(8〞) | 514 | 260 | 60.6 | 202.4 | 298.4 | 8×22.4 | 22.5 | 268 | 72.5 | 247.5 | 62.75 |

| DN250(10″) | 574 | 292 | 65.6 | 250.5 | 361.9 | 12×25.4 | 15 | 325 | 72.5 | 247.5 | 62.75 |

| DN300(12〞) | 662 | 337 | 76.5 | 301.5 | 431.8 | 12×25.4 | 15 | 403 | 80 | 237 | 80 |

| DN350(14″) | 717 | 368 | 76.2 | 333.32 | 476.2 | 12×28.4 | 15 | 436 | 80 | 237 | 80 |

PTFE Seat Butterfly Valve Manufacture Process

PTFE Seat Butterfly Valve Certificates

WRAS

CE

ISO 9001

EAC Russia