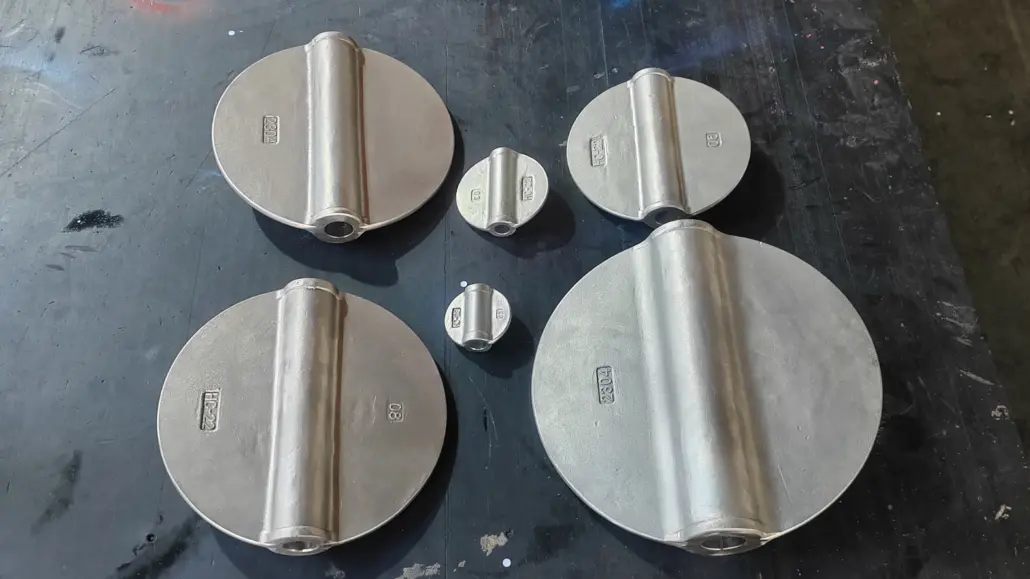

Titanium Alloy Concentric Butterfly Valve Disc

Titanium alloy refers to a metal composition with titanium as the main component and other elements such as aluminum and vanadium added. These alloys are known for their high strength-to-weight ratio, corrosion resistance, and excellent biocompatibility.

Some common applications of titanium alloys include aerospace components, medical implants, marine equipment, sports equipment, and automotive components. The exact composition of the alloy can vary depending on the desired properties and intended use.

Titanium is often sought after for its light weight and high strength, making it a popular choice for industries that value weight reduction and durability.

Basic Info

We produce valve bodies in various materials: Titanium Alloy, Ductile Iron(Ni lined), WCB (A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2205/2507),

can be applied to multinational standards: ASME, ANSI, DIN, JIS, ISO, API,etc.

whatever type of butterfly valve you need, contact us!