Wafer Soft Silicone Seat CF8M Disc Butterfly Valve

- Corrosion Resistance: silicone seat butterfly valve offers excellent corrosion resistance. They resist aggressive chemicals, solvents, and corrosive liquids.

- Non-Stick Properties: Silicone seat butterfly valve non-stick and low-friction properties minimize wear and enhance smooth operation.

- The CF8M disc is equivalent to 316 stainless steel and offers excellent resistance to pitting, corrosion and oxidation.

- The CF8M disc ensures strength and durability, making this valve suitable for high pressure and high temperature applications.

Basic Info of Silicone Seat Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | PFA, Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

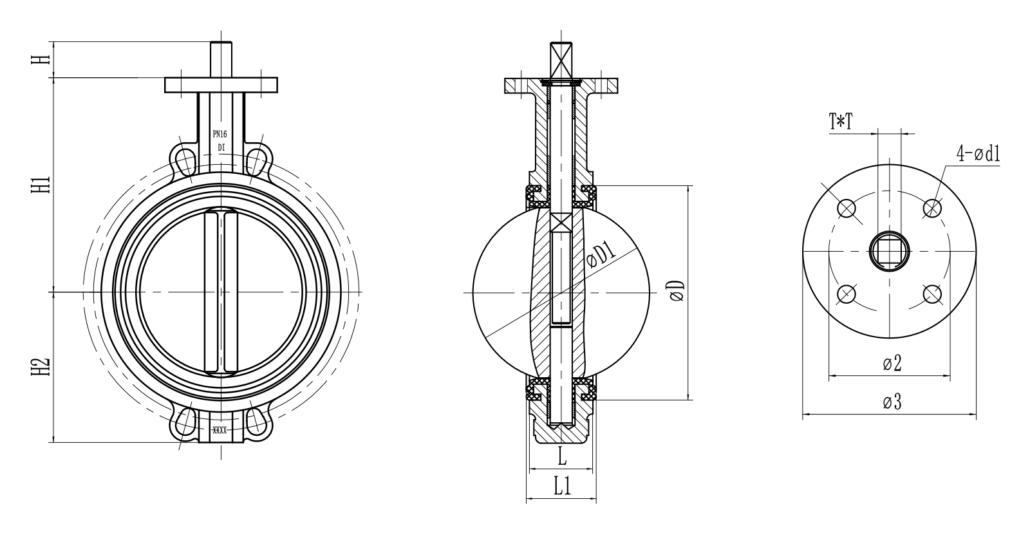

Paraments of Silicone Seat Butterfly Valve

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ø2 | ø3 | 4-ød1 | T*T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN25 | 55 | 33 | 26 | 29 | 30 | 122 | 48 | 50 | 65 | 7 | 11 |

| DN40 | 65 | 43.1 | 33 | 36 | 30 | 139 | 70 | 50 | 65 | 7 | 11 |

| DN50 | 82 | 53.08 | 42.5 | 46.1 | 30 | 140 | 60 | 70 | 90 | 10 | 11 |

| DN65 | 94 | 64.82 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11 |

| DN80 | 111.2 | 79.04 | 45.6 | 48.4 | 30 | 160 | 87 | 70 | 90 | 10 | 11 |

| DN100 | 140 | 104.04 | 52 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11 |

| DN125 | 166 | 123.3 | 56 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14 |

| DN150 | 187 | 155.68 | 56 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14 |

| DN200 | 246.8 | 201.9 | 60 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17 |

| DN250 | 301.5 | 250.45 | 68 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 352 | 301.55 | 78 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

| DN350 | 390 | 333.8 | 78 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22 |

| DN400 | 452 | 389 | 102 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27 |

| DN450 | 510 | 439.2 | 114 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27 |

| DN500 | 564 | 491.4 | 127 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36 |

| DN600 | 651 | 579 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36 |

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia