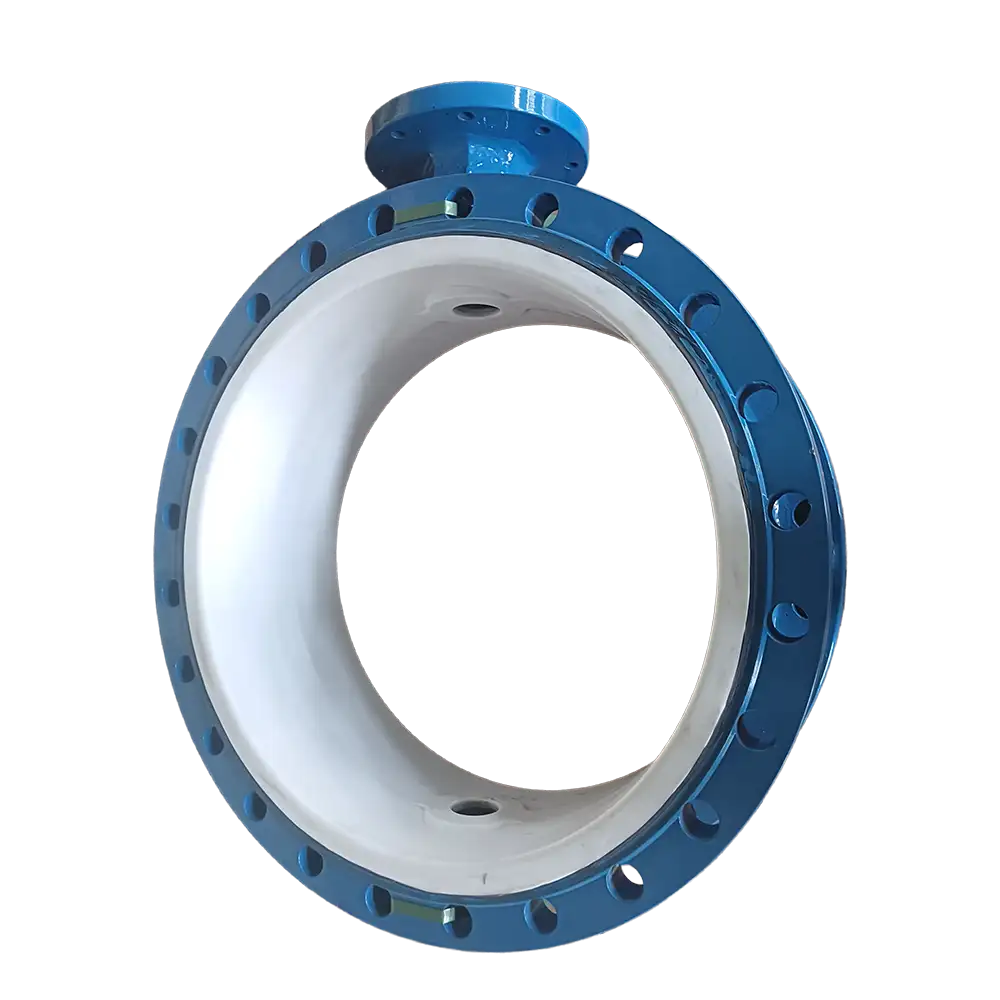

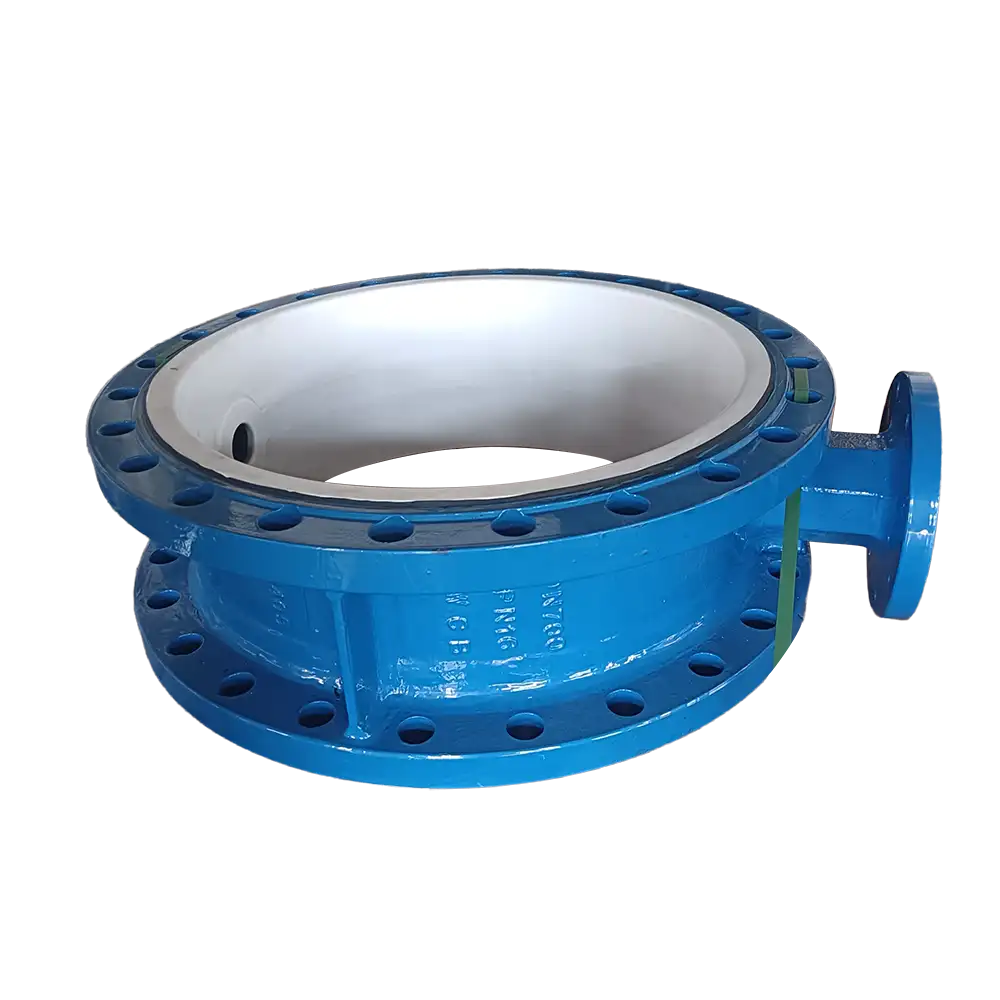

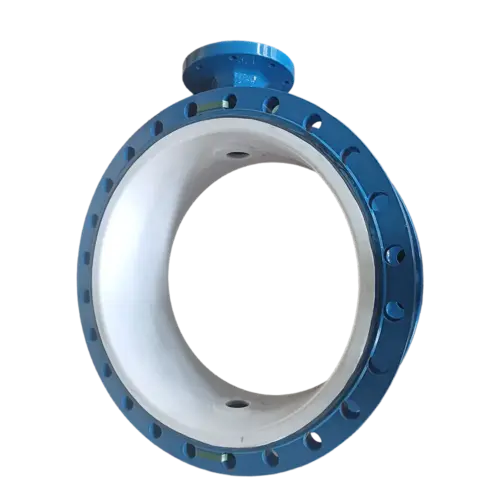

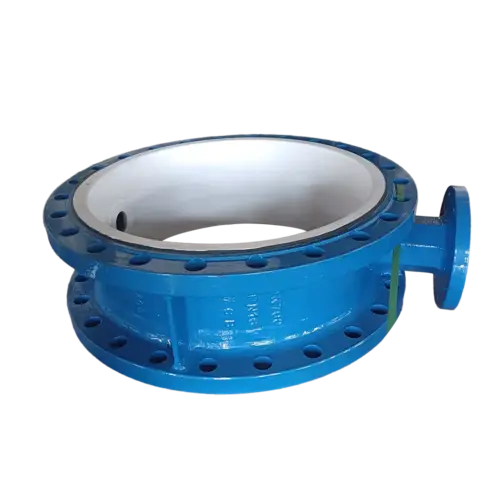

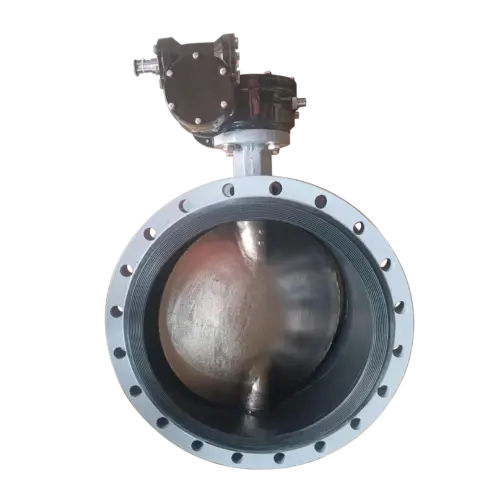

WCB Body PTFE Seated Flanged Butterfly Valve

Basic Info of PTFE Flanged Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

- WCB body provides excellent strength and durability, and ability to handle high-pressure and high-temperature applications.

- By using fluorine-lined material in the center line, the PTFE flanged butterfly valves body can be effectively prevented from being corroded and the service life of the valve is increased.

- The PTFE Seat is firmly bonded to the EPDM of the valve body through a vulcanization process. It is ensuring long-lasting sealing performance.

- The low friction coefficient of PTFE seat enables the valve to reduce wear during opening and closing. Thereby extending the service life of the valve.

- PTFE itself has non-stick properties, which can prevent the medium from adhering to the valve seat surface, ensuring the cleanliness and smoothness of the fluid channel.

- Compact structure: The PTFE flanged butterfly valve is made of ductile iron material, which can achieve a smaller size and lightweight structure, and is suitable for occasions with limited space.

- CF8M disc: Provides outstanding performance in demanding applications due to its superior corrosion resistance and mechanical strength.

Double Flanged Butterfly Valve Part Options

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

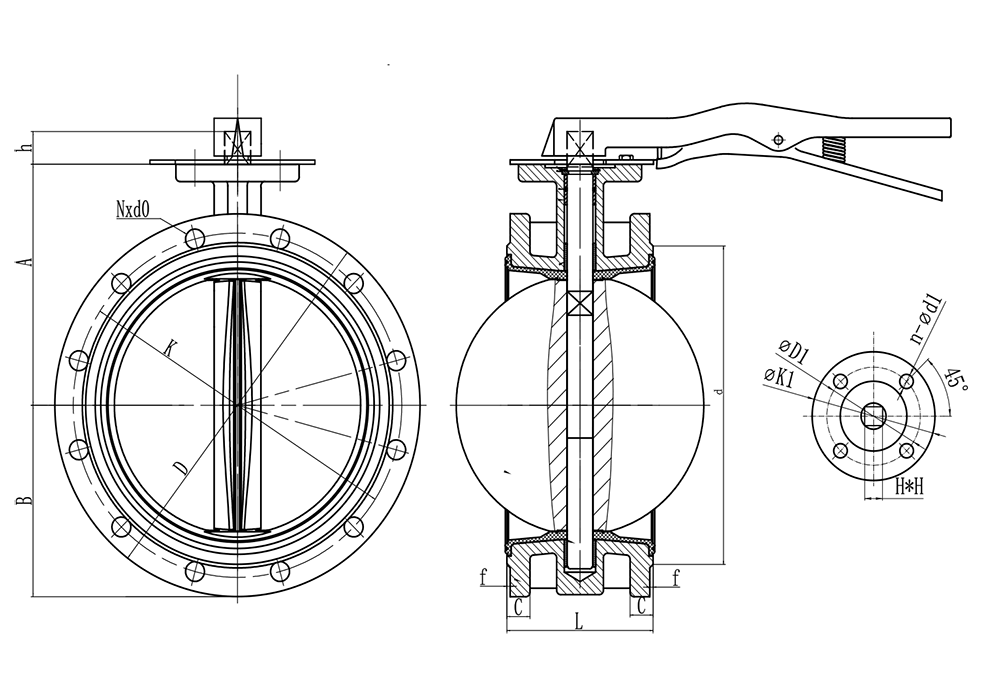

Paraments of PTFE Flanged Butterfly Valve

| DN | D | K | Nxd0 | d | C | L | f | A | B | K1 | D1 | n-d1 | HXH | h | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN50 | 165 | 125 | 4xø18 | 99 | 19 | 108 | 3 | 125 | 83 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN65 | 185 | 145 | 4xø18 | 118 | 19 | 112 | 3 | 142 | 93 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN80 | 200 | 160 | 8xø18 | 132 | 19 | 114 | 3 | 159 | 100 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN100 | 220 | 180 | 8xø18 | 156 | 19 | 127 | 3 | 165 | 130 | 90 | 70 | 4-10 | 11X11 | 30 | |||||

| DN125 | 250 | 210 | 8xø18 | 184 | 19 | 140 | 3 | 170 | 125 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN150 | 285 | 240 | 8xø22 | 211 | 20 | 140 | 3 | 185 | 143 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN200 | 340 | 295 | 8xø22 | 12xø22 | 270 | 20 | 152 | 3 | 228 | 150 | 125 | 102 | 4-12 | 17X17 | 35 | ||||

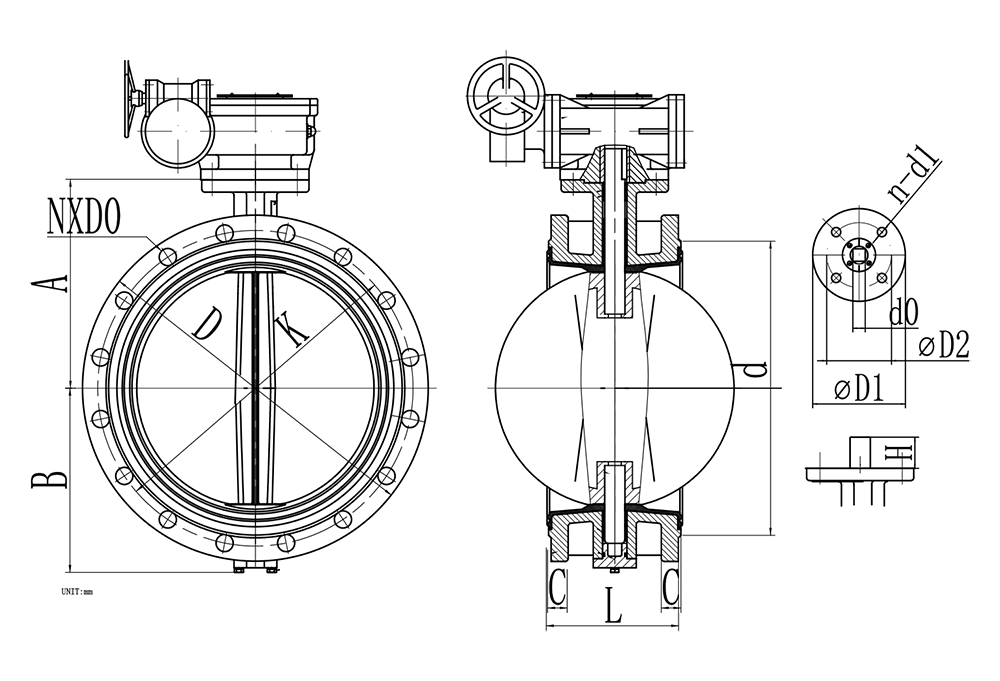

| DN | D | K | NxdO | d | C | L | f | A | B | D1 | D2 | n-d1 | d0 | H | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xø23 | 12xø28 | 319 | 22 | 165 | 3 | 279 | 200 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xø23 | 12xø28 | 370 | 24 | 178 | 4 | 303 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xø23 | 16xø28 | 429 | 24 | 28 | 190 | 4 | 330 | 245 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xø28 | 16xø31 | 480 | 28 | 36 | 216 | 4 | 370 | 272 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xø28 | 20xø34 | 582 | 609 | 26 | 32 | 229 | 4 | 430 | 339 | 210 | 165 | 4-22 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xø31 | 20xø37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 384 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xø31 | 24xø37 | 794 | 32.5 | 39.5 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | ø63.35 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xø34 | 24xø40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | ø63.35 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xø34 | 28xø40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | ø75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xø37 | 28xø43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | ø80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xø40 | 32xø49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | ø90 | 100 | |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia