Worm Gear OP PTFE Fully Lined Wafer Butterfly Valve

Basic Info of Wafer PTFE Lined Butterfly Valve

- The valve disc is fully lined with PTFE (polytetrafluoroethylene), a non-stick, chemical-resistant material. Because PTFE has excellent resistance to most chemicals, acids, bases and solvents.

- The smooth, low-friction surface of the PTFE valve disc helps prevent debris or media buildup, thereby reducing wear.

- PTFE can withstand a wide temperature range from -100°C to +180°C, making the valve suitable for both high and low temperature applications.

- The valve body is a split design, consisting of two bolted together. The split design allows for easier disassembly for maintenance or replacement of components such as the seat, disc or seal.

- By splitting the valve body, users can more easily inspect and replace parts that wear over time, so this type of butterfly valve is easy to maintain, thereby extending the overall service life of the valve.

- The valve stem adopts a dual-shaft design, which avoids the use of pins, ensures better sealing and reduces the risk of leakage.

Wafer PTFE Lined Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Wafer PTFE Lined Butterfly Valve Standards

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

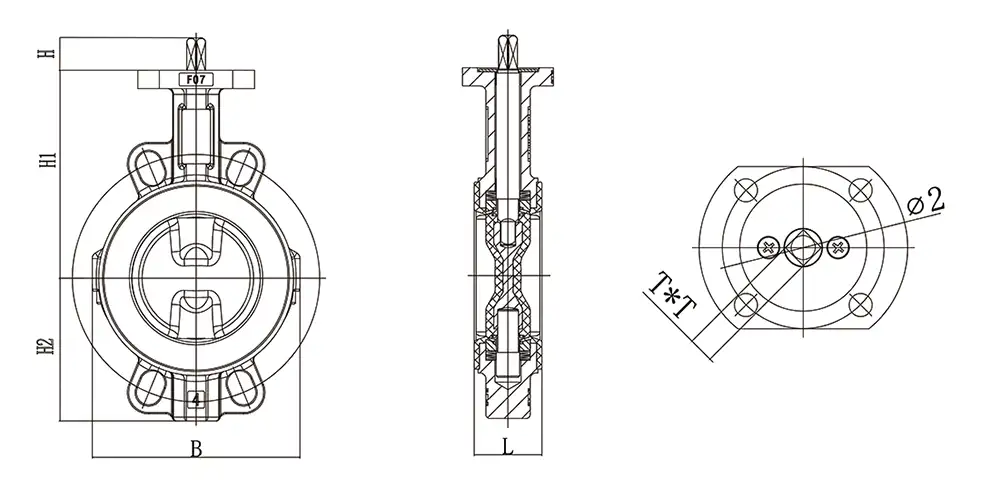

Paraments of PTFE Fully Lined Butterfly Valve

| SIZE | L | H1 | H2 | B | ø2 | T*T | H |

| DN50 | 43 | 134 | 68 | 100 | F05 | 9*9 | 25 |

| DN65 | 46 | 145 | 78 | 120 | F05 | 9*9 | 25 |

| DN80 | 46 | 150 | 80 | 140 | F05 | 9*9 | 25 |

| DN100 | 52 | 160 | 110 | 160 | F07 | 11*11 | 25 |

| DN125 | 56 | 178 | 130 | 190 | F07 | 14*14 | 25 |

| DN150 | 56 | 197 | 140 | 220 | F07 | 14*14 | 25 |

| DN200 | 60 | 239 | 175 | 277 | F10 | 17*17 | 30 |

| DN250 | 68 | 278 | 215 | 330 | F10 | 22*22 | 30 |

| DN300 | 78 | 315 | 250 | 380 | F12 | 22*22 | 30 |

| DN350 | 78 | 355 | 255 | 440 | F12 | 22*22 | 30 |

Manufacture Process of Wafer Butterfly Valve

Wafer PTFE Lined Butterfly Valve Certificates

WRAS

CE

ISO 9001

EAC Russia