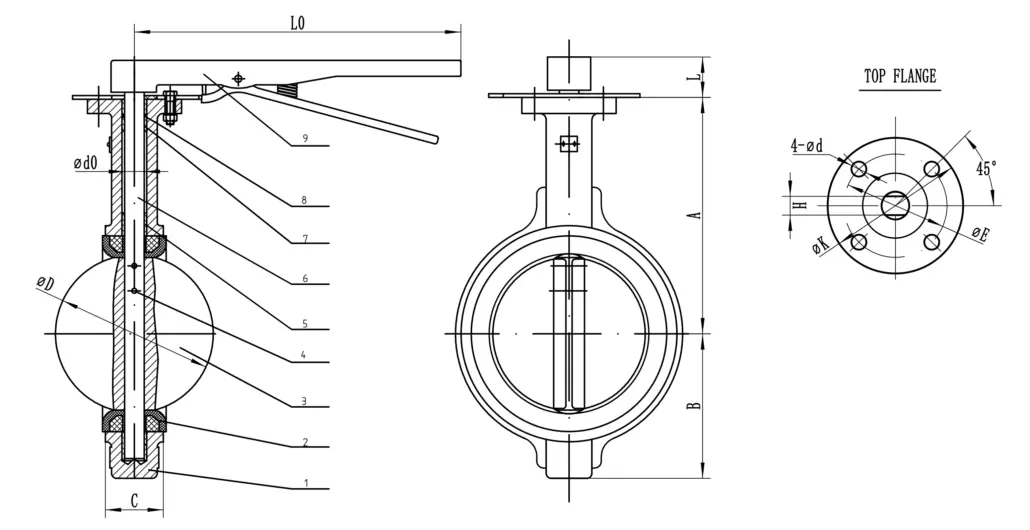

Non Ear Wafer Butterfly Valve

Basic Info

The main difference between earless butterfly valves and ordinary wafer butterfly valves

- Connection method: The earless butterfly valve adopts an ear-clip connection design, while the ordinary wafer butterfly valve adopts an ear-clip connection design. The earless design of the earless butterfly valve makes it smaller and more compact.

- Installation method: The installation of the earless butterfly valve is relatively simple. You only need to connect the two flanges and tighten the bolts to complete the installation. Ordinary wafer butterfly valves require lugs to be installed on the wafer connection flange and then fixed with bolts.

- In other respects, there is not much difference in function and performance between earless butterfly valves and ordinary wafer butterfly valves. They both have good sealing performance, low fluid resistance and reliable fluid control capabilities. The choice of which type of clamp-on butterfly valve to use should be determined based on actual needs and installation conditions.

- Besides, both two ears wafer butterfly valve and earless wafer butterfly valve can adopt Soft seat/hard back seat. the difference between them is the neck of two ears bfv is short and the earless bfv is suitable for DN≤75.

Paraments

| SIZE | A | B | C | D | do | H | L | LO | IS05211 | K | E | 4-φd | Weight |

| DN50(2〞) | 161 | 80 | 42 | 52.9 | 12.6 | 10 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 2.85 |

| DN65(2.5〞) | 175 | 89 | 45.8 | 64.5 | 12.6 | 10 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 3.2 |

| DN80(3〞) | 181 | 95 | 45.8 | 78.8 | 12.6 | 10 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 4.2 |

| DN100(4〞) | 200 | 114 | 52 | 104 | 15.77 | 12 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 5.2 |

| DN125(5〞) | 213 | 127 | 55 | 123.3 | 18.92 | 14 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 6.8 |

| DN150(6〞) | 226 | 139 | 55.8 | 155.6 | 18.92 | 14 | 30 | 266 | F07 | 90 | 70 | 4-φ9 | 8.1 |

| DN200(8〞) | 260 | 175 | 61.6 | 202.5 | 22.1 | 17 | 38 | 355 | F10 | 125 | 102 | 4-φ12 | 14.4 |

| DN250(10〞) | 292 | 203 | 67.2 | 250.5 | 28.45 | 22 | 38 | 355 | F10 | 125 | 102 | 4-φ12 | 20.6 |

| DN300(12〞) | 337 | 242 | 76.9 | 301.6 | 31.6 | 24 | 45 | 505 | F10 | 125 | 102 | 4-φ12 | 36.05 |

Manufacture Process

Certificates