Double Flanged PTFE Lining Butterfly Valve with Worm Gear

Features of Double Flanged PTFE Lining Butterfly Valve

- Corrosion resistance: The PTFE lining butterfly valve can effectively resist various corrosive media, such as acids, alkalis, solvents, etc.. The valve can work stably for a long time in harsh working environments.

- Sealing performance: The dual polarization structure ensures excellent sealing ability. It can prevent media leakage and ensure the safe operation of the pipeline system.

- Wear resistance: PTFE lining butterfly valve has excellent wear resistance. The valve has maintain stable performance during long-term use, and reduce the frequency of maintenance and replacement.

- Smooth fluid characteristics: There are no protrusions inside the valve body. when the fluid passes through the valve, little reduces resistance and pressure drop will occur, then it improves work efficiency.

- Light and easy operation: The structure of Double Flanged Butterfly Valve is light and flexible, easy to operate. In other words, it can open and close quickly, reducing the labor intensity of the operator.

- Reliable performance: The PTFE lining butterfly valve is made of high-quality materials and undergoes strict quality control and testing to ensure the valve has reliable performance and long life.

Standard of Double Flanged PTFE Lining Butterfly Valve

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

Parts Material of PTFE Lining Butterfly Valve

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

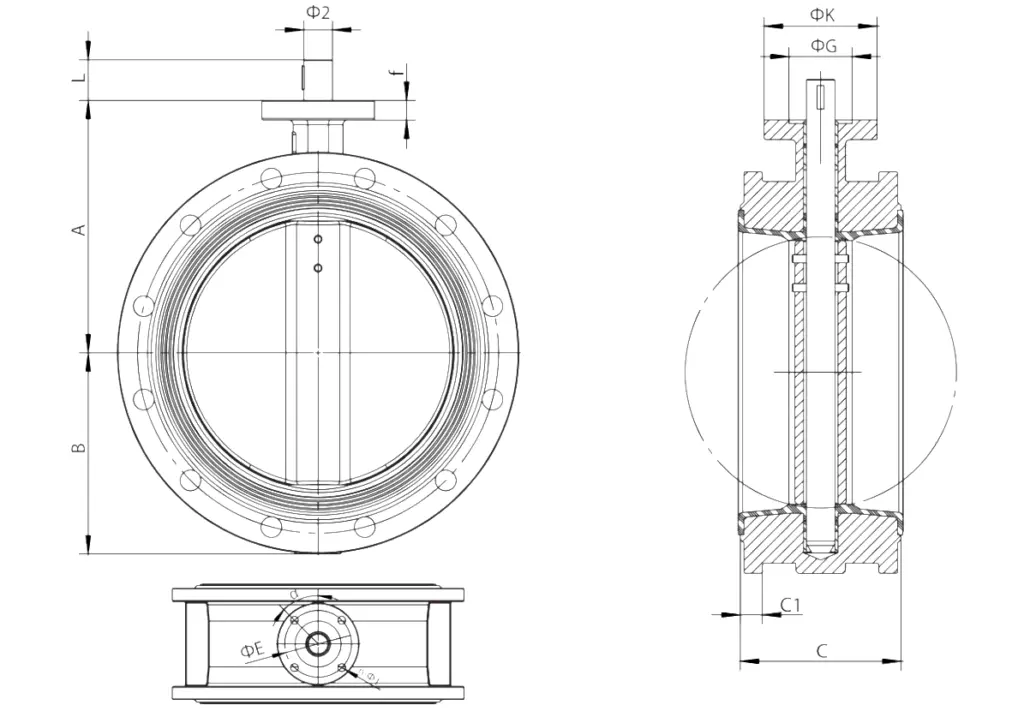

Paraments of PTFE Lining Butterfly Valve

| Specification | A | B | C | C1 | φE | φG | φK | L | n-φ1 | φ2 | |

| mm | inch | ||||||||||

| 50 | 2 | 120 | 83 | 108 | 19 | 50 | 35 | 65 | 28 | 4-8 | 12.6 |

| 65 | 2.5 | 130 | 93 | 112 | 19 | 50 | 35 | 65 | 28 | 4-8 | 12.6 |

| 80 | 3 | 145 | 100 | 114 | 19 | 50 | 35 | 65 | 28 | 4-8 | 12.6 |

| 100 | 4 | 155 | 114 | 127 | 19 | 70 | 55 | 90 | 28 | 4-10 | 15.77 |

| 125 | 5 | 170 | 125 | 140 | 19 | 70 | 55 | 90 | 28 | 4-10 | 18.92 |

| 150 | 6 | 190 | 143 | 140 | 23 | 70 | 55 | 90 | 28 | 4-10 | 18.92 |

| 200 | 8 | 205 | 170 | 152 | 23 | 102 | 70 | 125 | 45 | 4-12 | 22.1 |

| 250 | 10 | 235 | 198 | 165 | 28 | 102 | 70 | 125 | 45 | 4-12 | 28.45 |

| 300 | 12 | 280 | 223 | 178 | 28 | 102 | 70 | 125 | 45 | 4-12 | 31.6 |

| 350 | 14 | 310 | 270 | 190 | 28 | 125 | 85 | 150 | 45 | 4-14 | 31.6 |

| 400 | 16 | 340 | 300 | 216 | 31 | 140 | 100 | 175 | 51 | 4-18 | 33.15 |

| 450 | 18 | 375 | 340 | 222 | 31 | 140 | 100 | 175 | 51 | 4-18 | 38 |

| 500 | 20 | 430 | 355 | 229 | 34 | 140 | 100 | 175 | 57 | 4-18 | 41.15 |

| 600 | 24 | 500 | 410 | 267 | 37 | 165 | 130 | 210 | 72 | 4-22 | 50.65 |

| 700 | 28 | 560 | 478 | 292 | 37 | 254 | 200 | 300 | 82 | 8-18 | 63.35 |

| 800 | 32 | 620 | 529 | 318 | 41 | 254 | 200 | 300 | 82 | 8-18 | 63.35 |

| 900 | 36 | 685 | 584 | 330 | 41 | 254 | 200 | 300 | 110 | 8-18 | 75 |

| 1000 | 40 | 735 | 657 | 410 | 44 | 254 | 200 | 300 | 142 | 8-18 | 85 |

| 1200 | 48 | 917 | 799 | 470 | 44 | 298 | 230 | 350 | 150 | 8-22 | 105 |

| 1400 | 56 | 1040 | 919 | 530 | 50 | 356 | 260 | 415 | 200 | 8-33 | 120 |

| 1500 | 60 | 1050 | 965 | 570 | 50 | 356 | 260 | 415 | 200 | 8-33 | 140 |

| 1600 | 64 | 1150 | 1045 | 600 | 57 | 356 | 260 | 415 | 200 | 8-33 | 140 |

| 1800 | 72 | 1260 | 1156 | 670 | 57 | 406 | 300 | 475 | 280 | 8-40 | 160 |

| 2000 | 80 | 1323 | 1350 | 760 | 57 | 406 | 300 | 475 | 280 | 8-40 | 160 |

| 2200 | 88 | 1500 | 1430 | 800 | 62 | 483 | 370 | 560 | 300 | 12-40 | 180 |

Application of PTFE Lining Butterfly Valve

- Chemical Processing: PTFE lining resists chemicals, acids, alkalis, and solvents.

- Water Treatment: Protects valves from corrosion in chemical applications.

- Food and Beverage: Maintains sanitary conditions, prevents harmful contact.

- Pharmaceutical: Non-reactive PTFE ensures drug safety in production.

- Oil and Gas: Protects valves from corrosive fluids, suitable for refineries.

- Power Generation: Controls damaging fluids in power plants.

- Pulp and Paper: Handles harsh chemicals in pulping and bleaching processes.

Manufacture Process

Certificates of ZFA Butterfly Valve

WRAS

CE

ISO 9001

EAC Russia