API 609 is the butterfly valve standard established by the American Petroleum Institute. The API 609 standard specifies the design, manufacturing, material and testing requirements for butterfly valves. API 609 ensures certain performance and reliability of butterfly valves in industrial applications.

In short, as long as the butterfly valve complies with the API609 standard, it is called an API609 butterfly valve.

what a butterfly valve is

The Content of API609 Standard

1) API609 regulations on butterfly valve FTF dimensions.

API609 Standard covers the design and manufacturing of butterfly valves, including the connection type with the pipeline, structural form, structural length, etc.

- Connection form: wafer butterfly valve, flange butterfly valve, lug butterfly valve, grooved butterfly valve, welded butterfly valve, etc.

- Structural form: center line butterfly valve, eccentric butterfly valve (double eccentric butterfly valve, triple eccentric butterfly valve).

- Structural length(FTF): divided into A series and B series. A series covers clamp and lug types, and B series covers clamp lug and flange types. The flange type is divided into long structure and short structure.

Face-to-face Dimensions, Category A Valves (Lug and Wafer type):

| Face-to-face Dimensions, Category A Valves (Lug and Wafer type) | ||

| DN(INCH) | mm | in. |

| 2 | 43 | 1.69 |

| 2 1/2 | 46 | 1.81 |

| 3 | 46 | 1.81 |

| 4 | 52 | 2.06 |

| 5 | 56 | 2.19 |

| 6 | 56 | 2.19 |

| 8 | 60 | 2.38 |

| 10 | 68 | 2.69 |

| 12 | 78 | 3.06 |

| 14 | 78 | 3.06 |

| 16 | 102 | 4.00 |

| 18 | 114 | 4.50 |

| 20 | 127 | 5.00 |

| 24 | 154 | 6.06 |

| 30 | 165 | 6.50 |

| 36 | 200 | 7.88 |

| 42 | 251 | 9.88 |

| 48 | 276 | 10.88 |

Face-to-face Dimensions, Category B Valves:

| Face-to-face Dimensions, Category B Valves | ||||||||||||||||||

| Lug and Wafer type | Double-flanged Long type | Double-flanged Short type | ||||||||||||||||

| DN (inch) |

150lb | 300lb | 600lb | 150lb | 300lb | 600lb | 150lb | 300lb | 600lb | |||||||||

| mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | in. | |

| 3 | 48 | 1.88 | 48 | 1.88 | 54 | 2.12 | 203 | 8.00 | 282 | 11.12 | 356 | 14 | 114 | 4.50 | 180 | 7.09 | 180 | 7.09 |

| 4 | 54 | 2.12 | 54 | 2.12 | 64 | 2.50 | 229 | 9.00 | 305 | 12.00 | 432 | 17 | 127 | 5.00 | 190 | 7.48 | 190 | 7.48 |

| 6 | 57 | 2.25 | 59 | 2.31 | 78 | 3.06 | 267 | 10.50 | 403 | 15.88 | 559 | 22 | 140 | 5.50 | 330 | 8.27 | 210 | 8.27 |

| 8 | 64 | 2.50 | 73 | 2.88 | 102 | 4.00 | 292 | 11.50 | 418 | 16.50 | 660 | 26 | 152 | 6.00 | 350 | 9.06 | 230 | 9.06 |

| 10 | 71 | 2.81 | 83 | 3.25 | 117 | 4.62 | 330 | 13.00 | 457 | 18.00 | 787 | 31 | 165 | 6.50 | 250 | 9.84 | 250 | 9.84 |

| 12 | 81 | 3.19 | 92 | 3.62 | 140 | 5.50 | 356 | 14.00 | 502 | 19.75 | 838 | 33 | 270 | 7.00 | 178 | 10.63 | 270 | 10.63 |

| 14 | 92 | 3.62 | 117 | 4.62 | 155 | 6.12 | 381 | 15.00 | 762 | 30.00 | 889 | 35 | 190 | 7.50 | 290 | 11.42 | 290 | 11.42 |

| 16 | 102 | 4.00 | 133 | 5.25 | 178 | 7.00 | 406 | 16.00 | 838 | 33.00 | 991 | 39 | 216 | 8.50 | 310 | 12.20 | 310 | 12.2 |

| 18 | 114 | 4.50 | 149 | 5.88 | 200 | 7.88 | 432 | 17.00 | 914 | 36.00 | 1092 | 43 | 222 | 8.75 | 210 | 12.99 | 330 | 12.99 |

| 20 | 127 | 5.00 | 159 | 6.25 | 216 | 8.50 | 457 | 18.00 | 991 | 39.00 | 1194 | 47 | 229 | 9.00 | 230 | 13.78 | 350 | 13.78 |

| 24 | 154 | 6.06 | 181 | 7.12 | 232 | 9.13 | 508 | 20.00 | 1143 | 45.00 | 1397 | 55 | 267 | 10.50 | 390 | 15.35 | 390 | 15.35 |

| 26 | — | — | — | — | — | — | 559 | 22.00 | 1245 | 49.00 | 1448 | 57 | 292 | 11.50 | 410 | 16.14 | — | — |

| 28 | — | — | — | — | — | — | 610 | 24.00 | 1346 | 53.00 | 1549 | 61 | 292 | 11.50 | 430 | 16.93 | — | — |

| 30 | — | — | — | — | — | — | 610 | 24.00 | 1397 | 55.00 | 1651 | 65 | 318 | 12.52 | 450 | 17.72 | — | — |

| 32 | — | — | — | — | — | — | 660 | 26.00 | 1524 | 60.00 | 1778 | 70 | 318 | 12.52 | 470 | 18.50 | — | — |

| 36 | — | — | — | — | — | — | 711 | 28.00 | 1727 | 68.00 | 2083 | 82 | 330 | 12.99 | 510 | 20.80 | — | — |

| 38 | — | — | — | — | — | — | — | — | — | — | — | — | 410 | 16.14 | 530 | 20.87 | — | — |

| 40 | — | — | — | — | — | — | — | — | — | — | — | — | 410 | 16.14 | 550 | 21.65 | — | — |

| 42 | — | — | — | — | — | — | — | — | — | — | — | — | 410 | 16.14 | 570 | 22.44 | — | — |

| 48 | — | — | — | — | — | — | — | — | — | — | — | — | 470 | 18.50 | 630 | 24.80 | — | — |

2) API609 regulations on butterfly valve materials.

- Cast iron is the earliest material used for valves. Its biggest advantage is that it is easy to cast and has a low price. The disadvantage is that it has a weak pressure bearing capacity and cannot be used for medium and high pressure.

Ductile iron is one of the most commonly used materials for valves now. It has high tensile strength and can be used for medium and high pressure pipelines. It is very cost-effective. Therefore, it is generally the first choice for use in media that are not strong acids or strong alkalis.

But in any case, it also complies with the API609 regulations ASME B16.41. - WCB: The biggest feature of WCB is that it can be welded, especially for butterfly valves with extra large diameters. The cost of welding is much lower than that of casting. And it has better high temperature resistance. And it also includes low-temperature resistant LCB materials, which can be used in extremely cold areas.

But at the same time, it also has advantages and disadvantages, such as poor corrosion resistance compared to ductile iron.

Api609 stipulates that WCB must comply with ASME B16.34, - Stainless steel: Stainless steel is famous for its corrosiveness, and it is not easy to produce sand holes during the casting process. Common stainless steel grades include 304, 316 and 316L. In valves, it becomes CF8, CF8M, CF3, CF3M.

Duplex stainless steel: has higher strength and corrosion resistance than stainless steel, and the most common ones are 2205, 2507, etc. - Aluminum bronze: used in applications that require corrosion resistance and low friction. It can be used as a ship valve as a whole, or for components such as valve stems, valve seats and shaft sleeves.

Aluminum bronze and other materials comply with ASME B16.24.

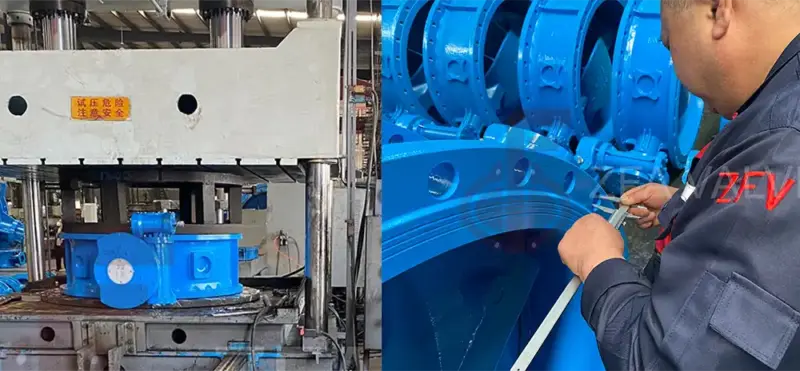

3) API609 regulations on butterfly valve inspection.

- Appearance: including the smoothness of the surface, whether there are blisters, whether there is damage, etc.

- Dimensions: including valve diameter, structural length, etc., to ensure compliance with design requirements.

- Sealing: including static sealing and dynamic sealing, water sealing and air sealing, sealing tests are conducted under different pressures and different media to ensure that the valve has no leakage in the closed state.

- Pressure: In accordance with API598 standards, check the pressure resistance performance of the butterfly valve under the design pressure.

The main features and applications of API 609 butterfly valve

1. Simple structure

Compared with other valves, the butterfly valve has a relatively simple structure, light weight and small size.

2. Quick opening and closing

The disc of the butterfly valve only needs to rotate 90 degrees, so it can be opened or closed quickly.

3. Low flow resistance

Since the valve disc of the butterfly valve rotates on the axis within the pipe, when it is fully opened, the resistance of the fluid is relatively small and has a lower pressure drop than most other valves.

4. High flow capacity

Butterfly valves usually have larger diameters, and ZFA valves can reach DN3000, which can control large flows.

5. Wide range of applications

Butterfly valves are suitable for low-pressure and medium-pressure systems, and are usually used to control media such as liquids, gases, and powders. The temperature range is usually based on the material and design of the butterfly valve.

6. Operation method

API 609 butterfly valve is usually operated by manual, pneumatic, electric or hydraulic methods.

Advantages of API 609 butterfly valve from ZFA Valves

1. We provide OEM services for many well-known valve brands around the world.

2. In the past 17 years, our production lines have been gradually improved. We have more than 30 machines that produce parts, processing, assembly. Furthermore, we have professional technicians and sales team, to ensure the comminication and product quality.

3. We have more than ten sets of molds on hand, including valve bodies, valve plates, handles, etc.