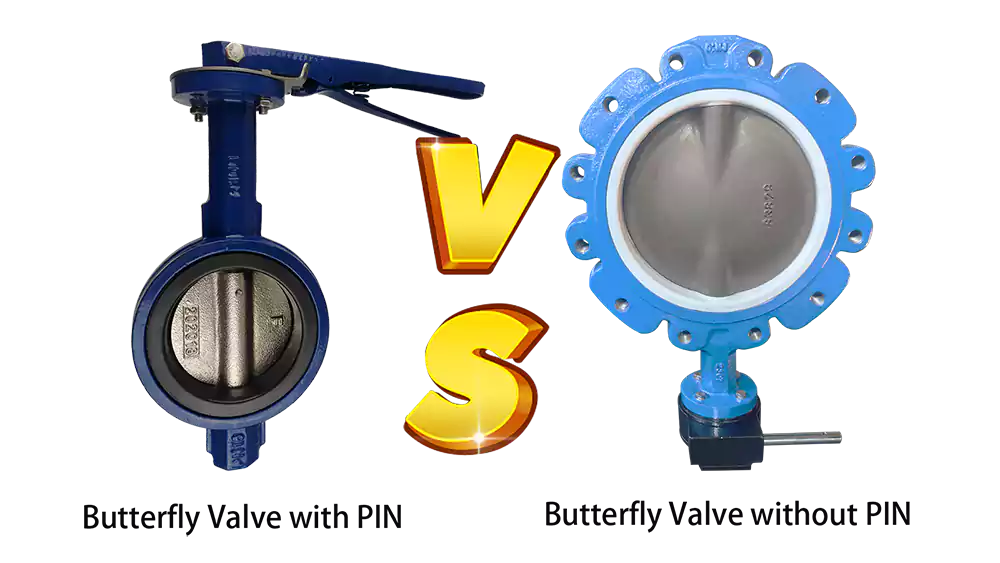

During the inquiry and purchase process, some customers often ask us why our main products are pinless butterfly valves. Compared with pinned butterfly valves, what are its advantages and disadvantages? Let’s compare them in detail below.

What is a pin?

The pin is a small conical metal nail, which used to penetrate the valve plate and connect the valve stem. It can prevent the relative position of the two parts from shifting.

so how the stem of pinless butterfly valve work?

what is the advantage and disadvantage of pinless butterfly valve and pinned butterfly valve?

- Appearance comparison – the pinned butterfly valve has an obvious pin head bulge in appearance, which is not as smooth and beautiful as the pinless butterfly valve, but in fact, the impact on the overall appearance is not particularly huge.

lets compare the valve disc directly, obviously, a valve with pin has hole on the disc.

2. Process comparison – The structural processing technology of pinned butterfly valves is relatively simple. You only need to drill holes of corresponding sizes on the valve plate and shaft, and wedge the pins. However, if maintenance is required after long-term use, it will be more troublesome to disassemble the shaft and valve plate. Because the pins are usually stacked and pressed with a press, it is not easy to take out the valve stem. Pinless butterfly valves are relatively complex in structure and technology, due to different ways of transmitting torque, but later maintenance and disassembly are easier to repair.

Above is the process of disc drilling hole for pin.

3. Stability comparison – because the pins can fix the pinned butterfly valve, its stability is better than the pinless structure. Pinless butterfly valves usually transmit torque and position, through other means (such as wedge-shaped valve discs, bearings, etc.), so after long-term operation, the axle and plate wear of the mating surfaces may affect the accuracy of the movement, but we have been working hard to solve this problem.

4. Sealing Comparison – In actual use of pinned butterfly valves, the medium may penetrate from the pinned area into the space between the valve plate and the valve stem. As a result, the pin becomes corroded and breaks and the valve becomes inoperable. Because pinless butterfly valves can reduce the risk of leakage.

To sum up, when comparing pin butterfly valves and pinless butterfly valves, objectively speaking, each design has its own characteristics and advantages, and we cannot simply say which one is better. As long as we choose the product that best suits our cost budget and our working conditions, it will be a good product for us.