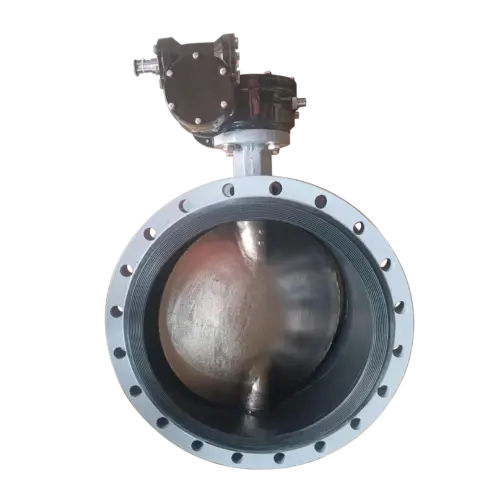

Soft Back Seat Nylon Coated Disc Wafer Butterfly Valve

Basic Info

The main difference between nylon coated disc soft back seat wafer butterfly valve and hard back seat wafer butterfly valve is the seat material:

- 1. Compared with the hard-backed valve seat, the soft-backed valve seat has a wider contact surface with the pipe flange, and the installation and sealing performance is better, without the need for a special flange for butterfly valves;

- 2. The soft-backed valve seat is highly replaceable and does not require any special tools. The replacement can be completed;

- 3. The wall thickness of the hard-backed valve body is relatively thin, and the valve body is easily deformed. The wall thickness of the soft-backed valve body is larger than that of the hard-backed valve body, and the valve body is heavier. The different shape designs prevent the valve body from deforming. Deformation.

- 4. The vulcanization process of the soft-backed valve seat is more perfect, and there will be no phenomenon of immature rubber of the hard-backed valve seat. The rubber performance is more reliable.

- 5. The soft-backed butterfly valve has small torque.

- 6. Nylon Coated disc butterfly valve: It has excellent friction reduction and self-lubricating properties. The operating torque is 40% lower than that of ordinary pinned butterfly valves.

- 7. Nylon Coated disc has excellent alkali and salt resistance, resistance to weak acid erosion, is inert to organic compounds, and has a wide range of adaptability

Basic Info of Wafer Butterfly Valve

Material

| Part Name | Material/Method |

| Body | Ductile Iron, Casting Iron, WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Disc | Ductile Iron(Coated/Lined), WCB, LCB/LCC, Stainless Steel, Duplex Stainless Steel, Aluminium Bronze |

| Seat | PFA, Rubber(EPDM/NBR/VITON), Nature Rubber, Silicon Rubber, PU, HNBR, Hypalon |

| Stem | 304, 316, 420(2Cr13), 431, 1.4462, 17-4PH, Monel |

| Actuator | Handlever, Worm Gear, Electric, Pneumatic |

Technical Parameters

| ITEM | Standard |

| Design | EN593 | API609 |

| Face to Face | EN558 | ISO5752 | API608 | BS5155-4 |

| Top Flange | ISO5211 |

| Flange Drilling | PN6 | PN10 | PN16 | ASME B16.5 CL150 | JIS 10K |

| Pressure Rating | PN6 | PN10 | PN16 | PN25 | CL150 | JIS 10K |

| Tightness Test | ISO5208 | API598 | EN12266-1 |

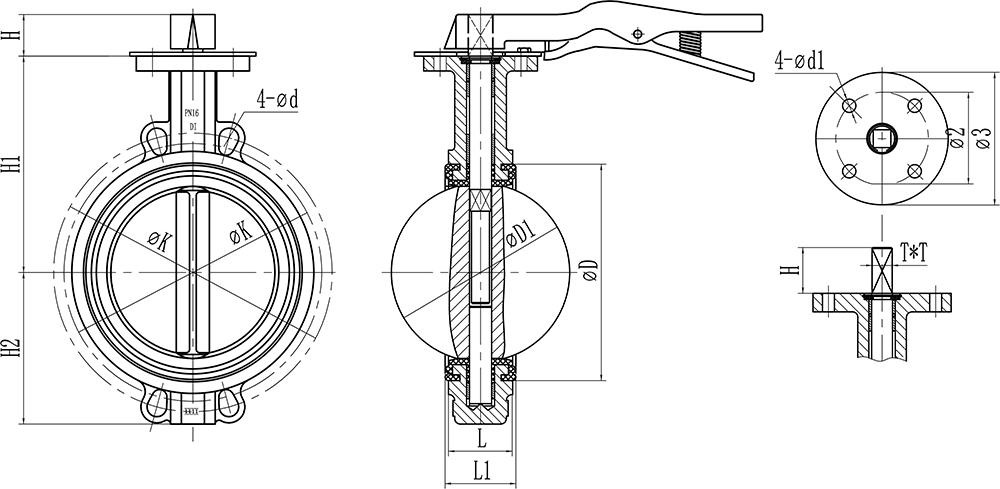

Paraments of Wafer Type Butterfly Valve

| SIZE | øK | 4-ød | øD | øD1 | L | L1 | H | H1 | H2 | ø2 | ø3 | 4-ødl | T*T | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN6 | PN10 | PN16 | CL150 | PN6 | PN10 | PN16 | CL150 | ||||||||||||

| DN50 | 110 | 125 | 120.6 | 4-ø14 | 4-ø19 | 4-ø19 | 82 | 53.08 | 42.5 | 46.1 | 30 | 140 | 60 | 70 | 90 | 10 | 11 | ||

| DN65 | 130 | 145 | 139.7 | 4-ø14 | 4-ø19 | 4-ø19 | 94 | 64.82 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11 | ||

| DN80 | 150 | 160 | 152.4 | 4-ø19 | 8-ø19 | 4-ø19 | 111.2 | 79.04 | 45.6 | 48.4 | 30 | 160 | 87 | 70 | 90 | 10 | 11 | ||

| DN100 | 170 | 180 | 190.5 | 4-ø19 | 8-ø19 | 8-ø19 | 140 | 104.04 | 52 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11 | ||

| DN125 | 200 | 210 | 215.9 | 8-ø19 | 8-ø19 | 8-ø22.4 | 166 | 123.3 | 56 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14 | ||

| DN150 | 225 | 240 | 241.3 | 8-ø19 | 8-ø23 | 8-ø22.4 | 187 | 155.68 | 56 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14 | ||

| DN200 | 280 | 295 | 298.4 | 8-ø19 | 8-ø23 | 12-ø23 | 8-ø22.4 | 246.8 | 201.9 | 60 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17 | |

| DN250 | 335 | 350 | 355 | 361.9 | 12-ø19 | 12-ø23 | 12-ø28 | 12-ø25.4 | 301.5 | 250.45 | 68 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 395 | 400 | 410 | 431.8 | 12-ø23 | 12-ø23 | 12-ø28 | 12-ø25.4 | 352 | 301.55 | 78 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

Manufacture Process of Butterfly Valve

Certificates

WRAS

CE

ISO 9001

EAC Russia