The opening and closing of the butterfly valve requires a power, and the device that provides this power is called an actuator. The actuator controls the opening and closing of the butterfly valve by providing a position signal to realize the circulation and stage functions of the pipeline system. Therefore, the actuator is an indispensable tool for butterfly valve operation. There are many types of butterfly valve actuator, each with its own advantages and disadvantages, so many factors must be considered to determine the appropriate actuator.

This article will solve your butterfly valve actuator selection confusion, elaborating from aspects such as butterfly valve size, pressure level and torque, butterfly valve medium, control accuracy, safety, etc.

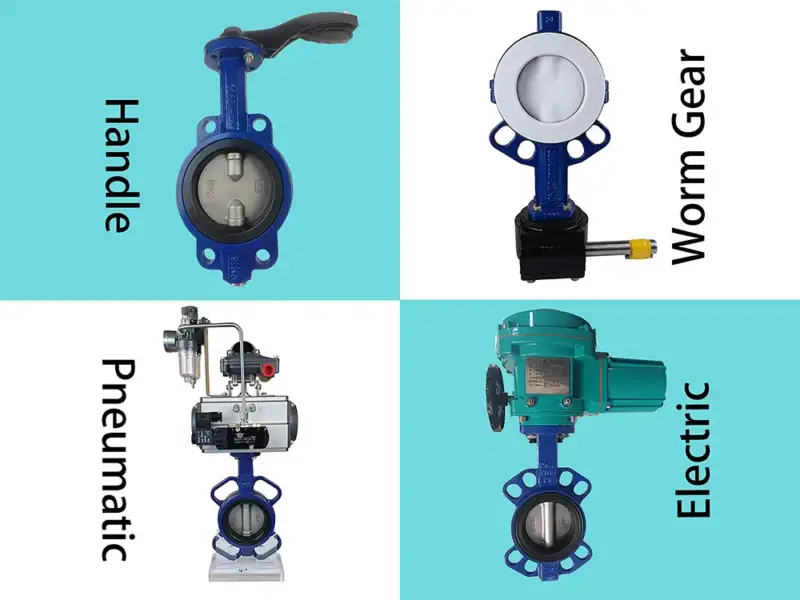

Type of butterfly valve actuator

a. Handle:

The butterfly valve handle is installed on the butterfly valve stem, and the opening and closing of the butterfly valve is controlled by the rotation of the handle. The butterfly valve handle not only has opening and closing functions, but also provides position indication. The material of the handle is generally cast steel, steel plate, cast iron, aluminum, etc. The handle is the most economical and commonly used butterfly valve actuator, but it also has limitations. It is suitable for butterfly valves with DN ≤ 250* and requires manual intervention. It is suitable for simple control needs.

b. Worm gear:

The worm gear actuator includes a worm gear and a transmission rod. By rotating the worm gear, the transmission rod will push the butterfly valve to open or close. Worm gear actuators can convert small input torque into large output torque, so worm gear actuators are often used in pipeline systems that require large torque or require frequent operations.

c. Electric:

Electric actuators control butterfly valves through motors, usually equipped with butterfly valves with DN ≥ 50 or requiring remote control.

Working principle of electric butterfly valve:

- The electric actuator includes a motor, a reducer and a travel switch. It controls the forward and reverse rotation or start and stop of the motor to open and close the butterfly valve.

- When the electric actuator receives the opening signal, the motor starts to rotate forward and transmits the rotational torque to the valve stem through the reducer, thereby opening the butterfly valve.

- When the electric actuator receives the closing signal, the motor starts to reverse and transfer the rotational torque to the valve stem, which rotates in the opposite direction, thereby closing the butterfly valve.

- The electric actuator detects the opening and closing status of the butterfly valve through the stroke switch. When the valve is fully opened or closed, the stroke switch will send a signal to stop the operation of the motor to protect the butterfly valve and the electric actuator.

- By controlling the forward and reverse rotation or start and stop of the electric actuator, the butterfly valve can be adjusted and controlled to achieve the required flow target.

d. Pneumatic:

The pneumatic actuator opens and closes the butterfly valve through the conversion of compressed air energy. It is mainly composed of a cylinder (piston, gear shaft, end cover, seal), and a triple component (air filter, pressure reducing valve and lubricator). . Suitable for occasions requiring remote and automated control.

Working principle of pneumatic butterfly valve:

When the pneumatic actuator receives the control signal, air will enter the cylinder, push the piston to cause the valve stem to rotate, and the butterfly valve opens.

When the control signal stops, the air is exhausted, the piston returns to its original position, the valve stem stops moving, and the butterfly valve closes.

By controlling the air supply and exhaust of the air source, the forward, reverse and stop control functions of the pneumatic actuator can be realized.

e. Hydraulic:

Hydraulic actuators are mainly based on the power system of hydraulic transmission, converting the pressure energy of the liquid into mechanical motion, which is used to rotate the valve stem to open and close the butterfly valve. The operation is relatively stable and suitable for high-demand fluid control systems.

Recommendations for butterfly valve actuator selection

a. Butterfly valve size and torque:

The size of the torque is the decisive factor in selecting the type of butterfly valve actuator.

Valve torque refers to the rotational torque that needs to be applied when a valve closes or opens. Correct calculation of valve torque is important because too little torque may cause the valve to fail to close completely, while too much torque may damage the valve.

|

Model |

Pressure for Butterfly Valve |

Pressure for Butterfly Valve |

||||

|

DN |

PN6 | PN10 | PN16 | PN6 | PN10 | PN16 |

| Torque, Nm (EPDM Seat) |

Torque, Nm (PTFE Seat) |

|||||

| 40 | 8 | 9 | 11 | 10 | 12 | 14 |

| 50 | 8 | 9 | 11 | 10 | 12 | 14 |

| 65 | 13 | 15 | 18 | 17 | 20 | 23 |

| 80 | 20 | 23 | 27 | 26 | 30 | 35 |

| 100 | 32 | 35 | 45 | 42 | 46 | 59 |

| 125 | 51 | 60 | 70 | 66 | 78 | 91 |

| 150 | 82 | 100 | 110 | 107 | 130 | 143 |

| 200 | 140 | 168 | 220 | 182 | 218 | 286 |

| 250 | 230 | 280 | 380 | 299 | 364 | 494 |

| 300 | 320 | 360 | 500 | 416 | 468 | 650 |

| 350 | 480 | 600 | 960 | 624 | 780 | 1248 |

| 400 | 710 | 920 | 1500 | 923 | 1196 | 1950 |

| 450 | 930 | 1355 | 1887 | 1209 | 1762 | 2453 |

| 500 | 1200 | 1600 | 2500 | 1560 | 2080 | 3250 |

| 600 | 2000 | 2600 | 4100 | 2600 | 3380 | 5330 |

| 700 | 2950 | 4100 | 6204 | 3835 | 5330 | 8065 |

| 800 | 4100 | 5400 | 8782 | 5330 | 7020 | 11417 |

| 900 | 6020 | 7092 | 12142 | 7826 | 9220 | 15785 |

| 1000 | 8400 | 11000 | 16122 | 10920 | 14300 | 20959 |

| 1200 | 12000 | 20000 | 26984 | 15600 | 26000 | 35079 |

*The following is the calculation formula

F=T/L

Among them: T is the valve torque, in Newton meters (N m); F is the valve force, in Newtons (N); L is the length of the valve operating rod, which refers to the distance from the valve axis to the end of the operating handle The unit is meters (m)

For example, the PN16 DN200 butterfly valve has a torque of 220 and a handle length of about 30cm.

Then the required force F=220/0.3=733N, about 73kg.

Therefore, usually if DN ≥ 250, we do not recommend the use of handles.

Other actuators are not subject to this restriction.

b. Working environment of Butterfly Valve Actuator

The working environment is also one of the factors that needs to be considered when selecting a butterfly valve actuator.

Temperature and humidity of the working environment. For example, in high or low temperature environments, you need to choose a butterfly valve actuator that can adapt to these extreme temperature conditions; Waterproof actuators are required in outdoor rainy environments, and explosion-proof actuators are required in dusty environments.

In a working environment with vibration or shock, it is necessary to choose a butterfly valve actuator with good vibration resistance.

c. Execution speed

Different actuators of butterfly valves with the same diameter have different switching speeds.

- Pneumatic actuator: Pneumatic actuators generally provide the fastest execution speed, usually between a few tenths of a second and tens of seconds, and the fastest can reach 0.05 seconds/time.

- Electric actuators: Electric actuators generally provide relatively fast execution speeds and can complete opening or closing operations in a few seconds to tens of seconds, depending on the model selected and the power of the motor.

- Hydraulic actuator: Hydraulic actuators can provide high torque output, but the disadvantage is that the execution speed can be relatively slow, usually between tens of seconds to minutes.

- Manual actuator: The execution speed of a manual actuator (worm gear and handle) depends on the operator’s operating speed. It is usually relatively slow and may take tens of seconds to several minutes to complete the operation.

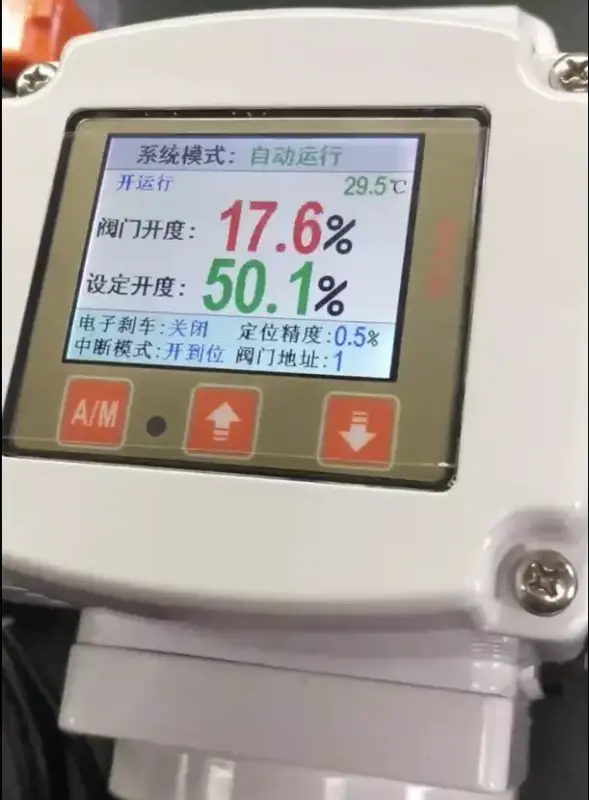

d. Control accuracy.

Different actuators have different control accuracy, which will directly affect the regulating performance of the butterfly valve.

- Electric actuator: Electric actuators usually provide high control accuracy and can achieve precise valve plate position control through the opening control module.

- Pneumatic actuator: The pneumatic actuator positioner can also achieve precise control. The positioner is equipped with a pressure sensor inside to detect the pressure of the air source. Based on different pressure signals, the positioner can determine the current position of the valve and the position that needs to be adjusted.

- Hydraulic actuator: The control accuracy of hydraulic actuators may be affected by the characteristics of the hydraulic system and is usually slightly lower than the control accuracy of electric and pneumatic actuators.

- Manual actuator: Manual actuator has the lowest control accuracy, completely relies on the operator’s manual operation, and cannot provide precise automatic control.

e. Cost of Butterfly Valve Actuator

Cost is a very important factor to consider in addition to performance, that is, while meeting control requirements, it is necessary to reduce costs as much as possible and improve performance-price ratio.

Butterfly valve actuators of the same caliber, hydraulic > pneumatic > electric > worm gear > handle.

f. Maintainability

It means that the butterfly valve actuator needs to be maintained and maintained during use, and its difficulty also needs to be taken into consideration. It is often necessary to select actuators that are easy to maintain to reduce maintenance costs and reduce downtime.

Therefore, factors that need to be considered when selecting a butterfly valve actuator include valve size and torque, working environment, execution speed, control accuracy, maintainability and cost, etc. to select the most suitable butterfly valve actuator product. I hope the introduction in this article can provide you with some help when choosing a butterfly valve actuator.