OEM Hard Back Seat WCB Mono Flanged Butterfly Valve

Basic Info

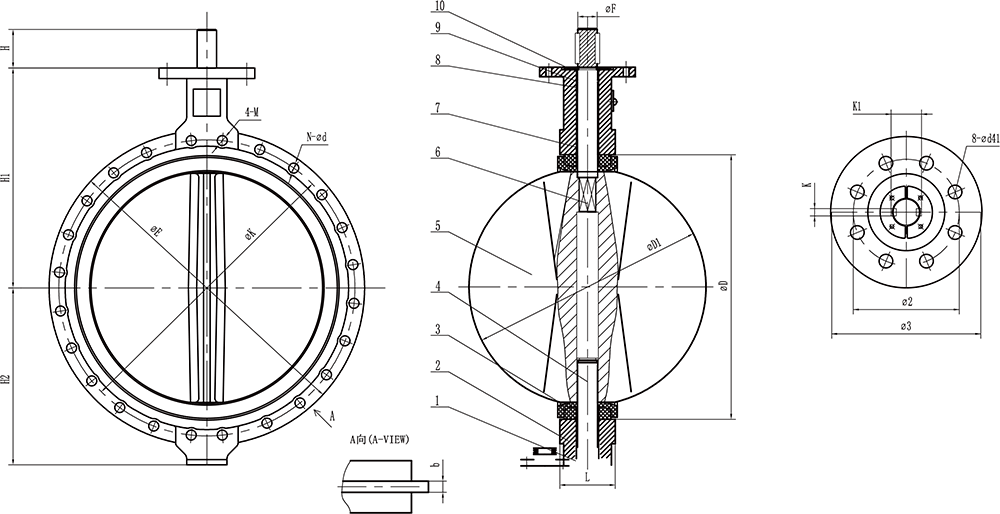

As shown in the figure, the mono flanged butterfly valve has only one flange surrounding the valve body.

Compared with wafer type butterfly valve, the connection of a mono flanged butterfly valve has better stability.

Generally speaking, the wafer type is used for DN<600. For DN >700, use single flange type.

Compared with double flange butterfly valve, the single flanged butterfly valve has shorter structural length, lighter weight and lower cost. As its TFT is same with wafer type.

The hard back seat is used to enhance sealing capabilities, ensuring minimal leakage and reliable operation under pressure. A hard back seat single flanged butterfly valve is cheaper than a soft back seat single flange butterfly valve. The valve body is made of WCB for excellent strength and durability. The mono-flange configuration simplifies installation and reduces space requirements, allowing direct installation between pipe flanges.

whatever type of butterfly valve you need, contact us!

Paraments

| SIZE | PN16 | ∅D | ∅D1 | L | b | H1 | H2 | ∅2 | ∅3 | 8-ød1 | H | øF | K | K1 | ||||

| øE | øK | N-ød | ||||||||||||||||

| DN700 | 28″ | 910 | 840 | 24-ø37 | 744.1 | 695 | 165 | 24 | 624 | 520 | 254 | 300 | 18 | 80 | 63.35 | 18 | 72.15 | |

| DN800 | 32″ | 1025 | 950 | 24-ø40 | 849.9 | 794.7 | 190 | 24 | 672 | 591 | 254 | 300 | 18 | 80 | 63.35 | 18 | 72.15 | |

| DN900 | 36″ | 1125 | 1050 | 24-ø40 | 4-M36 | 947 | 864.7 | 203 | 24 | 720 | 656 | 254 | 300 | 18 | 100 | 75 | 20 | 84.8 |

| DN1000 | 40″ | 1255 | 1170 | 24-ø43 | 4-M39 | 1053 | 965 | 216 | 33 | 800 | 721 | 254 | 300 | 18 | 100 | 85 | 22 | 95.8 |

| DN1200 | 48″ | 1485 | 1390 | 28-ø49 | 4-M45 | 1264.1 | 1160.6 | 254 | 42 | 941 | 864 | 298 | 350 | 22 | 100 | 105 | 28 | 117.8 |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia