1. A Concise Guide to Butterfly Valve Flow Characteristics

A butterfly valve is a flow control device used in a variety of industries. Such as water treatment, chemical processing, and HVAC systems. A butterfly valve uses a rotating disc that adjusts the angle of the disc to regulate fluid flow. The disc can be open, partially open, or closed depending on specific flow requirements.

In fluid control, butterfly valves are used as reliable on/off devices. They regulate or isolate the flow of fluid within a pipeline. You can operate them manually or through actuators such as pneumatic, electric, or hydraulic systems. Their design ensures minimal pressure drop when fully open, allowing for efficient management of large volumes of fluid.

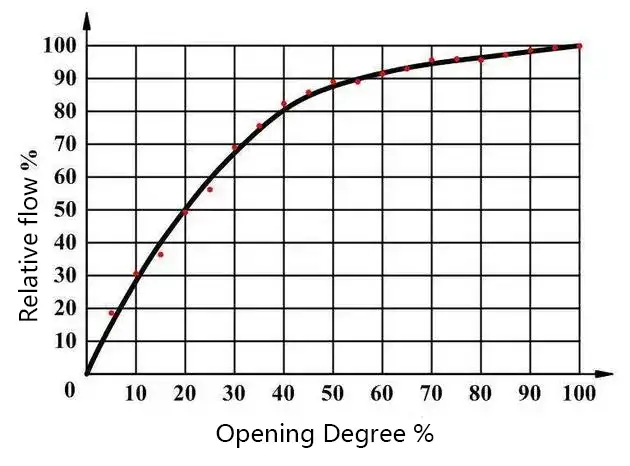

The flow characteristics describe how the flow rate changes when the valve goes from closed to open.

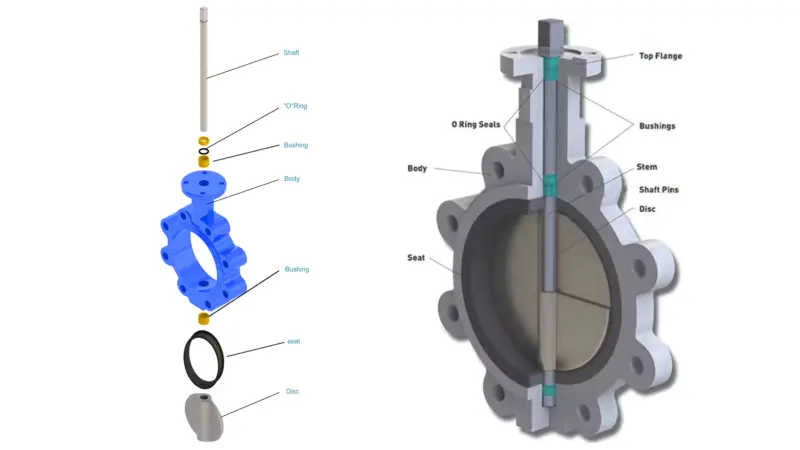

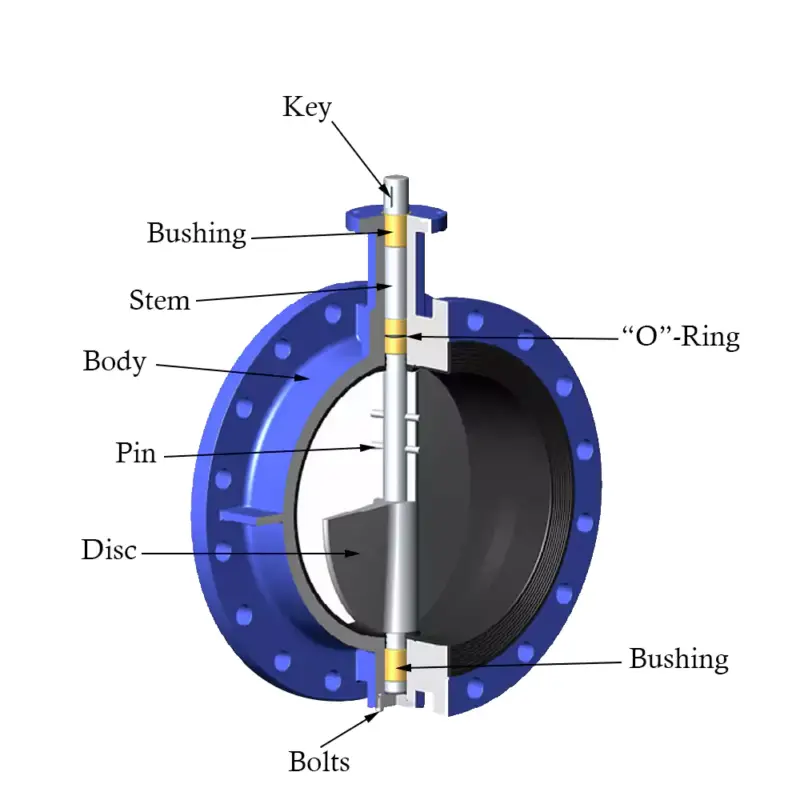

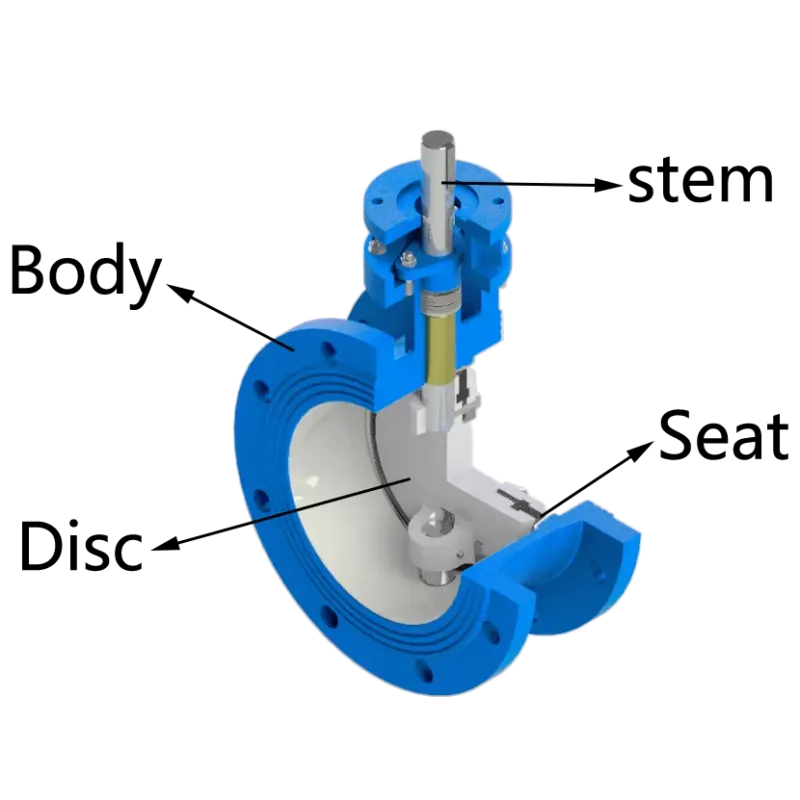

2. Basic Structure of a Butterfly Valve

A butterfly valve consists of several key parts: the valve body, stem, disc, seat, and actuator. The disc resembles the wings of a butterfly and rotates around a central axis. This design allows the valve to control the flow of fluid with a simple quarter-turn motion. When the valve is open, the disc is aligned with the fluid, minimizing obstruction. A 90-degree rotation is required to close, effectively stopping the flow.

3. Butterfly Valve Flow Characteristics

One of the key aspects of a butterfly valve is its flow characteristics, which refers to the fluid dynamics of the butterfly valve when controlling the flow of liquid or gas. It is also important to understand these characteristics so that the right valve for the specific application can ensure optimal performance, efficiency and safety.

3.1 Flow Coefficient (Cv)

The flow coefficient (Cv) is a key parameter used to describe the flow capacity of a valve. It is defined as the amount of water (gallons per minute) that can pass through the valve when the pressure drop across the valve is 1 psi in a specific position. The size of the CV value directly affects the valve’s regulating ability, that is, the amount of fluid flow. The larger the CV value, the greater the flow rate of the valve; conversely, the smaller the CV value, the smaller the flow rate of the valve.

Cv depends on valve size, design and opening. The size and shape of the valve disc affect the fluid flow rate of the butterfly valve.

– Smaller opening positions result in lower Cv values, which means that the valve significantly restricts the flow rate.

– Fully open valves generally have higher Cv values, indicating that the valve allows a larger volume of fluid to pass through with minimal restriction.

| Cv Value- Flow Rate Coefficient DN50 to DN1400 | |||||||||

| Size(mm) | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° |

| 50 | 0.1 | 5 | 12 | 24 | 45 | 64 | 90 | 125 | 135 |

| 65 | 0.2 | 8 | 20 | 37 | 65 | 98 | 144 | 204 | 220 |

| 80 | 0.3 | 12 | 22 | 39 | 70 | 116 | 183 | 275 | 302 |

| 100 | 0.5 | 17 | 36 | 78 | 139 | 230 | 364 | 546 | 600 |

| 125 | 0.8 | 29 | 61 | 133 | 237 | 392 | 620 | 930 | 1022 |

| 150 | 2 | 45 | 95 | 205 | 366 | 605 | 958 | 1437 | 1579 |

| 200 | 3 | 89 | 188 | 408 | 727 | 1202 | 1903 | 2854 | 3136 |

| 250 | 4 | 151 | 320 | 694 | 1237 | 2047 | 3240 | 4859 | 5340 |

| 300 | 5 | 234 | 495 | 1072 | 1911 | 3162 | 5005 | 7507 | 8250 |

| 350 | 6 | 338 | 715 | 1549 | 2761 | 4568 | 7230 | 10844 | 11917 |

| 400 | 8 | 464 | 983 | 2130 | 3797 | 6282 | 9942 | 14913 | 16388 |

| 450 | 11 | 615 | 1302 | 2822 | 5028 | 8320 | 13168 | 19752 | 21705 |

| 500 | 14 | 791 | 1674 | 3628 | 6465 | 10698 | 16931 | 25396 | 27908 |

| 600 | 22 | 1222 | 2587 | 5605 | 9989 | 16528 | 26157 | 39236 | 43116 |

| 700 | 36 | 1813 | 3639 | 6636 | 10000 | 14949 | 22769 | 34898 | 49500 |

| 800 | 45 | 2387 | 4791 | 8736 | 13788 | 20613 | 31395 | 48117 | 68250 |

| 900 | 60 | 3021 | 6063 | 11055 | 17449 | 26086 | 39731 | 60895 | 86375 |

| 1000 | 84 | 4183 | 8395 | 15307 | 24159 | 36166 | 55084 | 84425 | 119750 |

| 1200 | 106 | 5370 | 10741 | 19641 | 30690 | 46065 | 70587 | 107568 | 153450 |

| 1400 | 174 | 8585 | 17171 | 31398 | 49060 | 73590 | 112838 | 171710 | 245300 |

3.2 Flow Resistance and Pressure Drop

The flow resistance in a butterfly valve is affected by the geometry of the disc and its interaction with the fluid flow. The pressure drop across the valve is an indicator of the energy loss caused by this resistance. The pressure drop is usually highest when the valve is partially open. This is because the disc creates turbulence and disrupts the flow path.

A low pressure drop means that the valve allows fluid to pass with minimal resistance. This feature is critical in systems where maintaining pressure is critical to efficient operation. You will find that butterfly valves with streamlined designs promote smooth fluid flow, reducing energy consumption and operating costs.

– Large butterfly valves with streamlined disc designs generally have lower resistance.

– When the disc interrupts the flow, especially at small valve openings, the resistance is higher.

3.3 Butterfly Valve Flow Characteristics:Linear, Equal Percentage, and Fast Opening

The flow characteristics describe how the flow rate changes when the valve goes from closed to open. Butterfly valves usually exhibit one of the following flow characteristics:

– Linear flow characteristics: The flow rate changes proportionally with the valve position. For example, if the valve is 50% open, the flow rate will be approximately 50% of the maximum possible flow rate.

– Equal Percentage Flow Characteristics: Flow increases exponentially as the valve opens. In the early stages of opening, flow changes little, but as the valve opens further, flow increases rapidly. This is useful in applications that require fine control of low opening flow.

– Fast Opening Flow Characteristics: Flow increases rapidly at first, then levels off when the valve is fully open. This characteristic is ideal for on-off applications that require fast, full flow.

4. Factors Affecting Butterfly Valve Flow Characteristics

4.1 Valve Size

The size of a butterfly valve is a key factor in determining flow characteristics. As can be seen in the table above, larger valves generally have higher flow coefficients (Cv), meaning they can pass more fluid with less resistance. However, as valve size increases, sensitivity to changes in valve position also increases.

– Smaller valves tend to have more predictable, linear flow characteristics, making them easier to control in applications that require precise flow regulation.

– Larger valves may exhibit less control at small openings, as small adjustments in position can cause significant changes in flow.

4.2 Valve Types: Concentric vs. Eccentric Designs – Shape of the Disc

4.2.1 There are two main designs of butterfly valves: concentric and eccentric.

– Concentric butterfly valve: The disc is located in the center of the butterfly valve, with the shaft passing through the center of the disc. Typically used for low-pressure applications. The flow characteristics of these valves are generally more linear, but the flow resistance is greater due to the disc being centered.

– Eccentric butterfly valve: Both the disc and shaft are offset, with the disc slightly offset from the center. This design reduces contact between the disc and the seat, which reduces friction and allows for smoother operation. Eccentric valves typically exhibit an equal percentage flow characteristic, making them suitable for high-pressure applications that require precise flow control.

4.2.2 Concentric Butterfly Valve Flow Characteristics

Because the disc is centered, it creates more turbulence in the flow path than an eccentric butterfly valve. This results in higher flow resistance and pressure drop, especially when the valve is partially open.

Concentric butterfly valves are ideal for low-pressure applications, such as HVAC systems, water supply, and some industrial processes.

4.2.3 Eccentric Butterfly Valve Flow Characteristics

The offset disc design minimizes disruption to fluid flow, which reduces pressure drop and energy loss. This makes eccentric butterfly valves more energy efficient than concentric butterfly valves.

Eccentric butterfly valves are often used in high-pressure applications, including water treatment plants, oil and gas pipelines, and chemical processing facilities.

4.3 Disc Geometry and Design

The shape and design of the disc play an important role in influencing the flow characteristics of a butterfly valve.

– Thin disc: Reduces flow resistance by allowing the fluid to pass around the disc more smoothly, especially in larger valves. This design can improve flow efficiency and reduce pressure drop.

– Streamlined disc design: Further reduces turbulence and flow disruption, resulting in a more predictable flow pattern.

In contrast, a flat or thicker disc may cause more turbulence and result in higher flow resistance, especially in valves with smaller openings.

4.4 Valve Position and Opening Angle

The position of the valve directly affects the flow rate and flow coefficient (Cv). Butterfly valves are very sensitive to small changes in position, especially in the first 15-30 degrees of opening.

– At low opening angles (0-30 degrees), flow increases rapidly, making it difficult to precisely control flow at small openings.

– Between 30-70 degrees, flow rate continues to increase in a more controlled manner, making this range ideal for applications that require modulation and flow control.

– Beyond 70 degrees, the valve is close to fully open, and further adjustments have little effect on flow rate.

5. Comparison with other valve types

5.1 Butterfly Valves vs. Globe Valves

When you compare butterfly valves to globe valves, you will notice a clear difference in flow characteristics. Butterfly valves excel in applications that require fast and efficient flow control. Their design allows for rapid opening and closing, which is ideal for systems that require fast response times.

5.2 Butterfly Valves vs. Ball Valves

Comparing butterfly valves to ball valves, you will find that both provide effective flow control. However, butterfly valves have a simpler mechanism, which means lower lifecycle costs. They are particularly effective in systems with a wide pressure range. Ball valves are known for their tight sealing capabilities and have excellent shutoff performance. This makes them ideal for applications where leak prevention is a priority.

6. Practical Applications of Butterfly Valves

6.1 Water Treatment

In water treatment facilities, butterfly valves help manage the flow of water through different purification stages. Because butterfly valves have the lowest pressure drop of almost all valves, they are ideal for this application. This is critical to maintaining water quality and system efficiency.

6.2 Chemical Processing

In chemical processing plants, butterfly valves have proven their reliable performance in handling a wide range of chemicals, ensuring safe and efficient operation. This is because butterfly valves are durable and corrosion-resistant, which is critical in environments with frequent chemical exposure.

7. Limitations of Butterfly Valves

7.1 Pressure Limitations

When using butterfly valves, you may encounter pressure limitations. These valves generally handle low-pressure to high-pressure systems effectively. However, they may not perform well in vacuum and ultra-high pressure environments. The design of butterfly valves, with their thin discs and compact structure, can limit their ability to withstand extreme pressures.

7.2 Temperature Limitations

Temperature limitations also affect butterfly valves. Valves work best within a specific temperature range. Extreme temperatures, whether hot or cold, can affect the materials and sealing capabilities of the valve. High temperatures can cause valve components to expand, resulting in potential leaks. Conversely, low temperatures can make the material brittle, increasing the risk of failure. Understanding the temperature limits of butterfly valves is essential to maintaining system integrity and preventing operational issues.

8. Conclusion

Butterfly valves stand out for their lightweight design, cost-effectiveness, and efficiency of fluid management systems. Their versatility makes them a top choice for industries that require precise flow control. Their simple design leads to lower costs, especially for larger valve sizes.