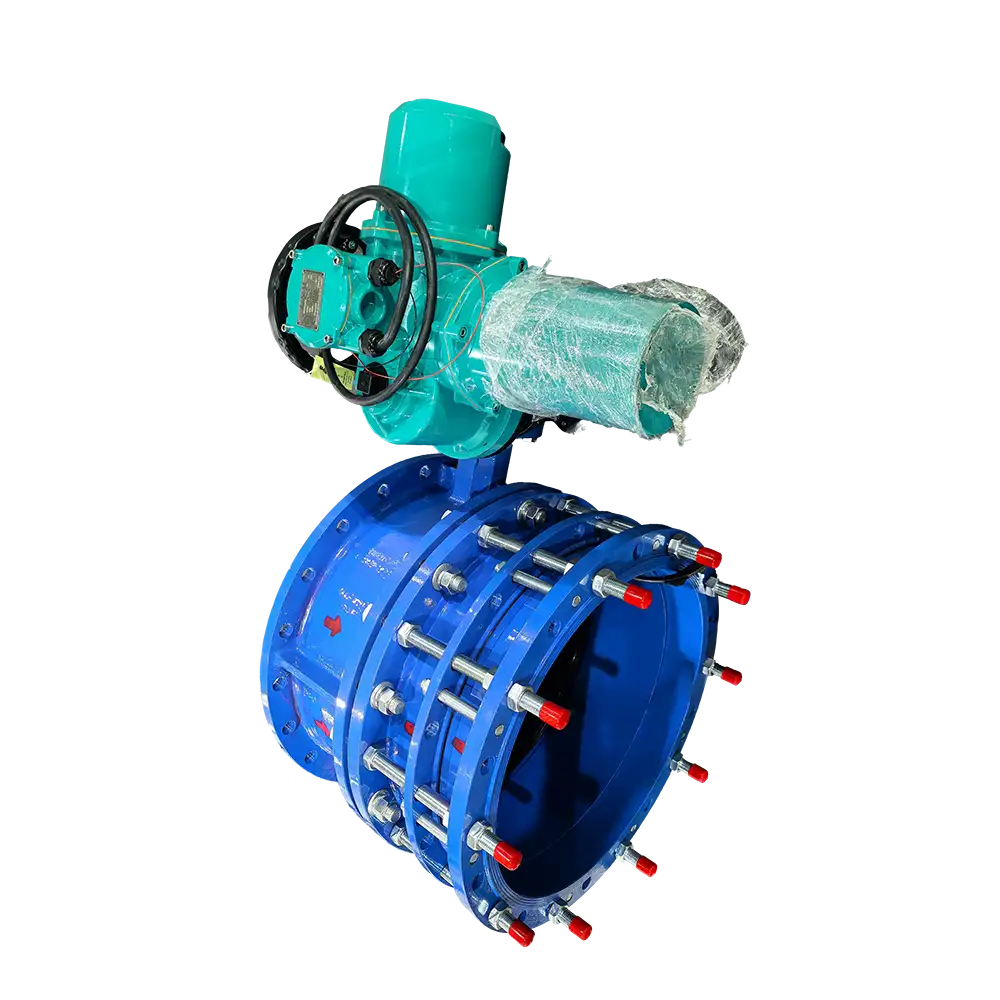

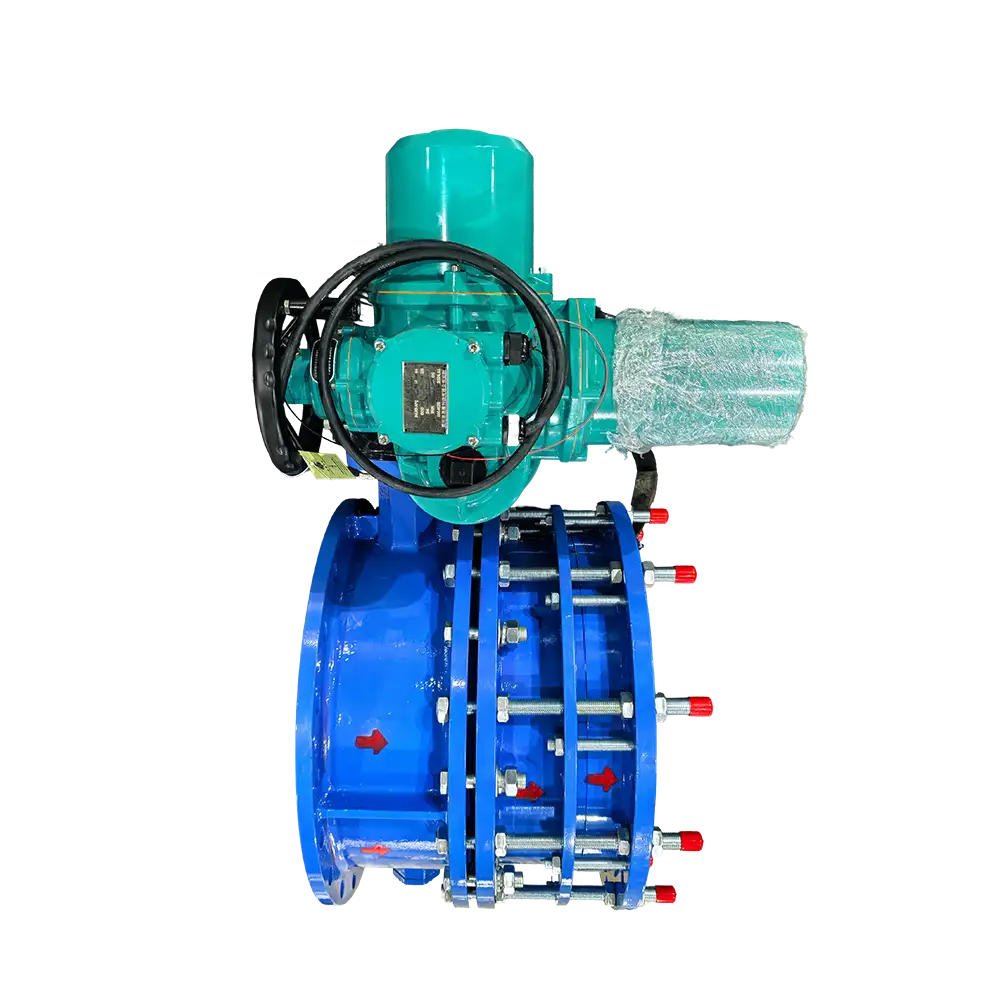

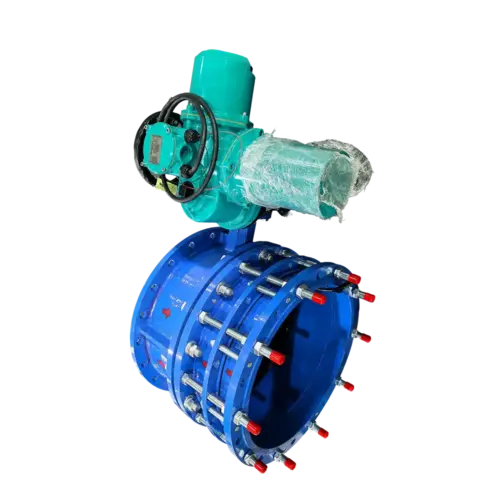

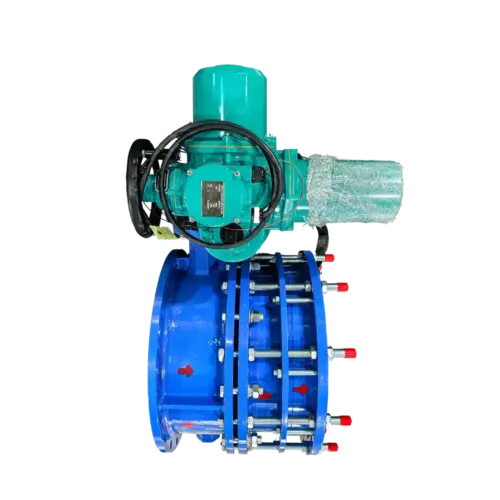

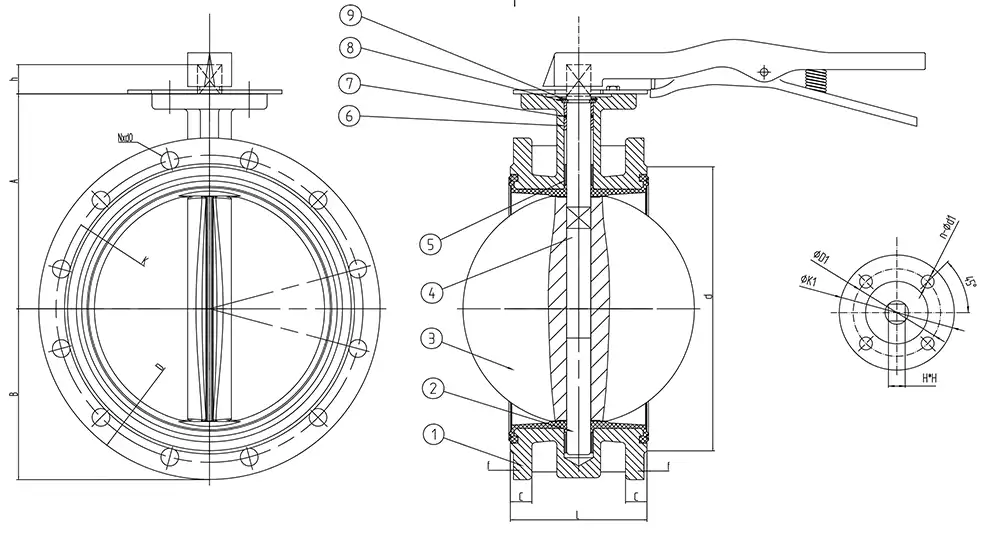

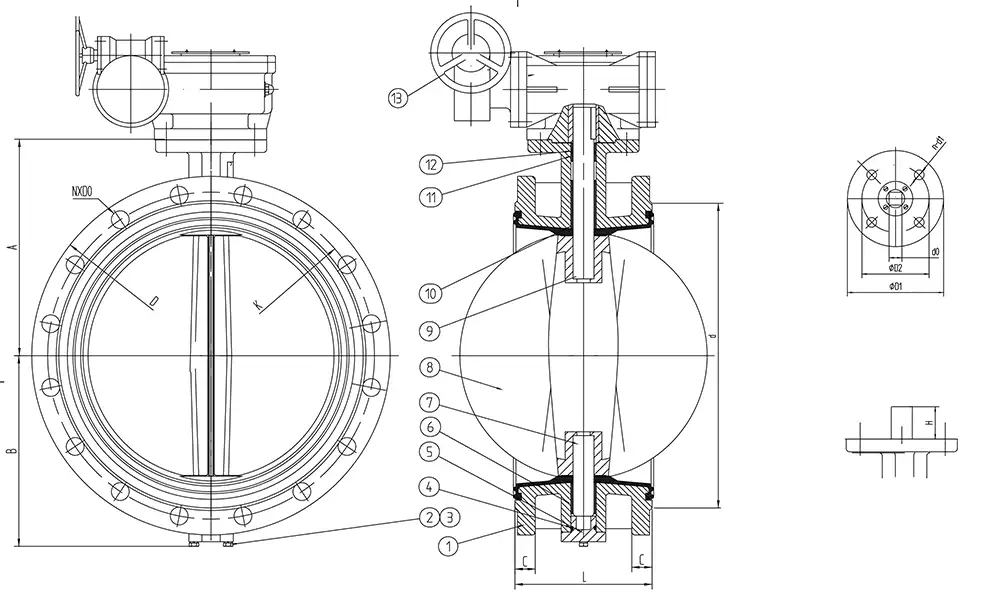

Electric Double Flanged Butterfly Valve with Dismantling Joints

Basic Info of Butterfly Valve with Dismantling Joint

- Ductile iron material: It has high tensile strength, wear resistance, temperature resistance and other characteristics, ensuring long-lasting performance and corrosion resistance. so it it a best material for soft seat butterfly valve.

- Soft valve seat: EPDM has good sealing and wear resistance, and can achieve zero leakage.

- Replaceable soft seat: When the valve seat is worn and affects use, this type of seat can be replaced without damaging the valve body, so that it facilitates maintenance, extends the service life of the valve, and reduces maintenance costs.

- Double flange design ensures the soft seat butterfly valve is easy for installation and is suitable for various pipeline systems, including pipeline end systems.

- The butterfly valve with dismantling joint can be adjusted in length, leaving flexible disassembly space to simplify the installation and removal of valves and other equipment in the pipeline. It also makes maintenance or replacement easier.

- The butterfly valve with dismantling joint provides flexibility during installation, compensating for slight lateral and longitudinal errors, minimizing the need for precise adjustments.

- The electric actuator is integrated with the control system to enable remote operation and real-time monitoring.

- Manual override can be configured for use in power outages or emergency situations.

Paraments of Flanged Butterfly Valve

| DN | D | K | Nxd0 | d | C | L | f | A | B | K1 | 01 | n-d1 | HXH | h | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN50 | 165 | 125 | 4xφ18 | 99 | 19 | 108 | 3 | 139 | 80 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN65 | 185 | 145 | 4xφ18 | 118 | 19 | 112 | 3 | 146 | 89 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN80 | 200 | 160 | 8xφ18 | 132 | 19 | 114 | 3 | 150 | 95 | 65 | 50 | 4-8 | 11X11 | 30 | |||||

| DN100 | 220 | 180 | 8xφ18 | 156 | 19 | 127 | 3 | 177 | 114 | 90 | 70 | 4-10 | 11X11 | 30 | |||||

| DN125 | 250 | 210 | 8xφ18 | 184 | 19 | 140 | 3 | 178 | 125 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN150 | 285 | 240 | 8xφ22 | 211 | 20 | 140 | 3 | 201 | 139 | 90 | 70 | 4-10 | 14X14 | 30 | |||||

| DN200 | 340 | 295 | 8xφ22 | 12xφ22 | 270 | 20 | 152 | 3 | 230 | 170 | 125 | 102 | 4-12 | 17X17 | 35 | ||||

| DN | 0 | K | Nxd0 | d | C | L | f | A | B | 01 | 02 | 0-d1 | d0 | H | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN250 | 395 | 405 | 350 | 355 | 12xφ23 | 12xφ28 | 319 | 22 | 165 | 3 | 266 | 198 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN300 | 445 | 460 | 400 | 410 | 12xφ23 | 12xφ28 | 370 | 24.5 | 178 | 4 | 298 | 223 | 125 | 102 | 4-12 | 22X22 | 35 | ||

| DN350 | 505 | 520 | 460 | 470 | 16xφ23 | 16xφ28 | 429 | 24.5 | 26.5 | 190 | 4 | 310 | 254 | 150 | 125 | 4-14 | 22X22 | 35 | |

| DN400 | 565 | 580 | 515 | 525 | 16xφ28 | 16xφ31 | 480 | 245 | 28 | 216 | 4 | 340 | 278 | 175 | 140 | 4-18 | 27X27 | 50 | |

| DN500 | 670 | 715 | 620 | 650 | 20xφ28 | 20xφ34 | 582 | 609 | 265 | 32 | 229 | 4 | 430 | 348 | 175 | 140 | 4-18 | 36X36 | 50 |

| DN600 | 780 | 840 | 725 | 770 | 20xφ31 | 20xφ37 | 682 | 720 | 30 | 36 | 267 | 5 | 500 | 410 | 210 | 165 | 4-22 | 36X36 | 60 |

| DN700 | 895 | 910 | 840 | 24xφ31 | 24xφ37 | 794 | 325 | 395 | 292 | 5 | 560 | 480 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN800 | 1015 | 1025 | 950 | 24xφ34 | 24xφ40 | 901 | 35 | 41 | 318 | 5 | 620 | 530 | 300 | 254 | 8-18 | φ6335 | 80 | ||

| DN900 | 1115 | 1125 | 1050 | 28xφ34 | 28xφ40 | 1001 | 36 | 44 | 330 | 5 | 685 | 605 | 300 | 254 | 8-18 | φ75 | 100 | ||

| DN1000 | 1230 | 1255 | 1160 | 1170 | 28xφ37 | 28xφ43 | 1112 | 40 | 50 | 410 | 5 | 735 | 670 | 300 | 254 | 8-18 | φ80 | 100 | |

| DN1200 | 1455 | 1485 | 1380 | 1390 | 32xφ40 | 32xφ49 | 1328 | 45 | 57 | 470 | 5 | 917 | 780 | 350 | 298 | 8-22 | φ90 | 100 | |

Manufacture Process of Butterfly Valve

Certificates of Zfa Valve

WRAS

CE

ISO 9001

EAC Russia