Vulcanized Seat CF8 Disc Flanged DN1500 Large Diameter Butterfly Valve

Basic Info of Large Diameter Butterfly Valve

- Body Material: This large diameter butterfly valve uses WCB to make the valve body.

- Flange connection: The double flange design is very strong for DN1500 large diameter butterfly valve. It is designed to connect to flanged piping systems per standards like DIN, ANSI B16.1, or ISO. Flanged connections ensure secure installation and easy maintenance.

- Seal: The vulcanized seat provides 100% bidirectional sealing. It is suitable for full vacuum to PN10 pressure. The sophisticated vulcanization process ensures its durability and vacuum handling ability.

- The CF8 disc and vulcanized seat make it suitable for non-corrosive media, and specific seat materials can be selected depending on the fluid (e.g. EPDM seats for drinking water, Viton seats for chemicals).

- Top Flange comply with standards such as API 609, MSS SP-67 or ISO 5211 (for actuator mounting).

- Applications: Suitable for water, wastewater, gas or mild chemical systems.

Butterfly Valve Parts

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

|---|---|---|---|---|

| Body | Cast Iron(GG25) Ductile Iron(GGG40/50) |

A216 A217 A105(forged) |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M |

2205 2507 1.4529 |

| Disc | Ductile Iron with Ni coated Ductile Iron with nylon coated Ductile Iron with PTFE/EPDM lined Stainless Steel Duplex Stainless Steel Bronze |

SS304/ CF8 SS316/CF8M SS304L/CF3 SS316L/CF3M 2205 2507 1.4529 |

2205 2507 1.4529 |

|

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

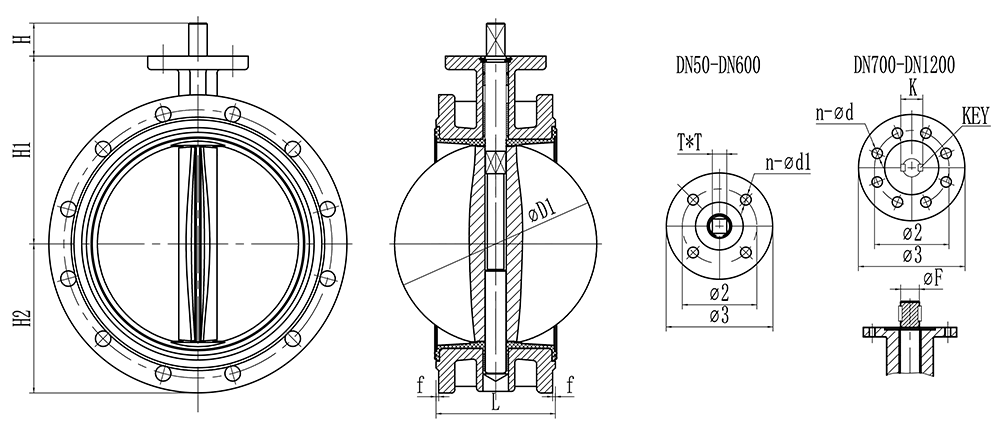

Paraments of DN1500 Large Diameter Butterfly Valve

| SIZE | L | øD1 | f | H1 | H2 | ø2 | ø3 | n-ød1 | T*T | H | øF | K | KEY |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN50 | 108 | 52.6 | 3 | 139 | 80 | 70 | 90 | 4-10 | 11 | 30 | —— | —— | —— |

| DN65 | 112 | 64.3 | 3 | 146 | 89 | 70 | 90 | 4-10 | 11 | 30 | —— | —— | —— |

| DN80 | 114 | 78.8 | 3 | 150 | 95 | 70 | 90 | 4-10 | 11 | 30 | —— | —— | —— |

| DN100 | 127 | 104.0 | 3 | 177 | 114 | 70 | 90 | 4-10 | 11 | 30 | —— | —— | —— |

| DN125 | 140 | 123.3 | 3 | 179 | 125 | 70 | 90 | 4-10 | 14 | 30 | —— | —— | —— |

| DN150 | 140 | 155.7 | 3 | 201 | 139 | 70 | 90 | 4-10 | 14 | 30 | —— | —— | —— |

| DN200 | 152 | 202.4 | 3 | 230 | 170 | 102 | 125 | 4-12 | 17 | 40 | —— | —— | —— |

| DN250 | 165 | 250.4 | 3 | 267 | 198 | 102 | 125 | 4-12 | 22 | 40 | —— | —— | —— |

| DN300 | 178 | 301.5 | 4 | 298 | 223 | 102 | 125 | 4-12 | 22 | 45 | —— | —— | —— |

| DN350 | 190 | 333.3 | 4 | 310 | 254 | 125 | 150 | 4-14 | 22 | 45 | —— | —— | —— |

| DN400 | 216 | 389.6 | 4 | 340 | 278 | 140 | 175 | 4-18 | 27 | 50 | —— | —— | —— |

| DN450 | 222 | 440.5 | 4 | 375 | 315 | 140 | 175 | 4-18 | 27 | 50 | —— | —— | —— |

| DN500 | 229 | 491.6 | 4 | 430 | 348 | 140 | 175 | 4-18 | 36 | 50 | —— | —— | —— |

| DN600 | 267 | 592.5 | 5 | 500 | 410 | 165 | 210 | 4-22 | 36 | 60 | —— | —— | —— |

| DN700 | 292 | 695.0 | 5 | 560 | 480 | 254 | 300 | 8-18 | —— | 80 | 63.35 | 72.15 | 18*70 |

| DN800 | 318 | 794.7 | 5 | 620 | 530 | 254 | 300 | 8-18 | —— | 80 | 63.35 | 72.15 | 18*70 |

| DN900 | 330 | 864.7 | 5 | 685 | 605 | 254 | 300 | 8-18 | —— | 100 | 75 | 84.80 | 20﹡90 |

| DN1000 | 410 | 965.0 | 5 | 735 | 670 | 254 | 300 | 8-18 | —— | 100 | 85 | 95.80 | 22﹡90 |

| DN1200 | 470 | 1160.6 | 5 | 917 | 780 | 298 | 350 | 8-22 | —— | 100 | 105 | 117.80 | 28*90 |

Manufacture Process of Butterfly Valve

Certificates of Zfa Butterfly Valve

WRAS

CE

ISO 9001

EAC Russia